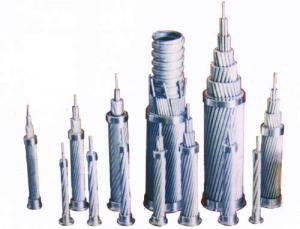

ACCC Conductor -Low Price and Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 10000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction ACCC Conductor consists of composite core and annealed aluminumformed wires outer layer. The annealed aluminum formed wires outer layer anditsadjacent layer are trapezoidal crosssection. CFCC is a kind of carbonfiber product with high performance. Compared with the traditional aluminumconductors steel reinforced, it has series ofadvantages including high heat resistance, high current carrying capacity, hightensile strength, light weight, low-sag, saving costs of towers and poles anddecreasing the covering area etc.

2.Speification

high-temperature resistance,

low thermal expansion coefficient,

anti-corrosion, high current carrying capacity,

low line l

3.ACCC product is the newest type stranded conductor , usually used in the overhead power transmission lines. It has double capacity of ACSR at the same conditions.

4.Increased Power Transfer

When compared to an ACSR that can be strung on the same towers, ACCC conductors will carry about 28% more annealed aluminum in a trapezoidal configuration giving greatly increased conductivity; the carbon core provides increased strength and virtually eliminates high temperature sag allowing more efficient operation at up to 180°C. This can double current capacity (ampacity) over the ACSR.

5.Reduced High Temperature Sag

The coefficient of thermal expansion of ACCC conductor at its final condition is eight times less than typical ACSR, and the ACCC core is approximately two and a half times lighter than steel. ACCC conductors sag very little due to thermal expansion which eliminates this as a significant design consideration.

6.Energy Efficiency

Using more aluminum with better conductivity reduces losses at every temperature of operation. When operating as a High Temperature Low Sag (HTLS) conductor, the higher operating efficiency can reduce line losses and their associated emissions by more than 35%. This results in more power delivered to be sold and can result in lower power generation costs.

Lower initial sag at normal tensioning allows for lowering initial tensions on weaker towers and during line upratings or allows designing for smaller power towers on new lines.

Uprating lines and Building New Lines

7.Pictures

- Q: Four lines only reached a phase line, at the other end all charged, I use the digital pen! In addition, I often check the cable when the cable current through the dot digital pen voltage symbols sometimes have time to disappear, in other bare wires when the test keys are normal! What is this going on! Ask the heroes to give the younger brother a complete point of the answer! More

- Bookstore tool book should have "communication project budget", I do is what you say, the budget is divided into estimates and budget, is two steps. So that is not very clear. But what is needed is the preliminary design of the project. The budget is needed for design and drawings. Internal management of this piece, the main thing is that you need to do what the project department, and are generally very complicated

- Q: I would like to ask my new workshop power consumption of about 500KW, injection molding machine, 60KW . 40KW . 20KW . the other 20KW, how much should the wire? Respectively how to use lines and switches more

- A very practical proposal: to your local talent market, a large job fairs, and the best and your professional relevance, to see, look at what positions, pay how? You can also chat with hr, you will understand.

- Q: The data line is my online to buy the extension of the line, has been able to use, and today suddenly can not charge the electricity, and pop up the tips, which is why? More

- What do you want to do? Do network cabling buried? Or in the building after the tube?

- Q: Wire and cable CCC product consistency is what

- Wire of course, is to use a good slightly, the first life, ah, can not buy cheap because of cheap, like China's top ten brands to buy the brand on the purchase of these brands I feel very good ah, Po Sheng , Luneng Taishan, Far East, Shenghua cable, on the up, prosperous photoelectric, Nexans Nexans these brands of wire is still very good. The landlord you can go to the above to learn more detailed information ah, the top ten wire brand is very detailed, the landlord can understand very clearly, the above brand is very good, my father last time to go above to see, and then buy

- Q: What is the difference between "wire" and "cable"?

- Simple point, the plotter is generally used to out of the line map, the general is the Academy of Engineering, the Bureau of the use of a CAD map, and some can also be some effect of the general effect of the map, generally suitable for color requirements are not very high, but right Print accuracy requires a high place. Inkjet machine can be divided into indoor and outdoor ink, outdoor irritating smell, for outdoor advertising like the effect of the map, the indoor no irritating smell, the general subway, as well as other indoor advertising are used this out of

- Q: Why this cable has not yet been certified

- Electromechanical products are usually used to be assembled into parts, multiple parts and then assembled into a single product, the number of products or the number of pieces measured

- Q: What are the varieties of wire and cable (detailed point)

- Cable regardless of the definition of the number of elements in the definition of a few such as: YJV-3 * 50 + 1 * 16 calculated the number of lines is always a different, different wire rules Model input: bv-2 * 2.5 / bv-3 * 4 (different material), bv-2 * 2.5 + 3 * 4 (the same material)

- Q: Why does the bird stand on the wire without anything, but if people touch it,

- Please provide air-conditioned three-leg socket photo, because you said "open inside is 2.5 square line ~ is a separate line ~" is not very understanding.

- Q: How are various wire and cable models named?

- Cable type a lot, here to give an example: ZRC-YJV22-0.6 / 1KV3 * 25 +2 * 16 This model specification means: C-class flame retardant (ZRC) XLPE insulated (YJ) PVC jacket 22) steel tape armor (0.6 / 1KV) 0.6 / 1 kV (3 * 25) 3 25 square (+ 1 * 16) plus two 16 square copper conductor flame retardant copper core steel tape armored cross-linked poly Ethylene insulated PVC sheathed low voltage electric power.

- Q: What are the T and T, s of the wire and cable test type?

- The expression is not very clear, it should be said to wear a tube, if a single wear on the line 100. Outside diameter 60mm.

Send your message to us

ACCC Conductor -Low Price and Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 10000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches