High Quality 550C Abrasive Sanding Mesh Screen - Fiberglass Mesh Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

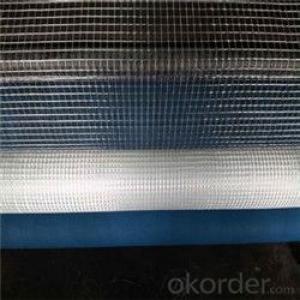

1.Structure of Abrasive Sanding Mesh Screen Description:

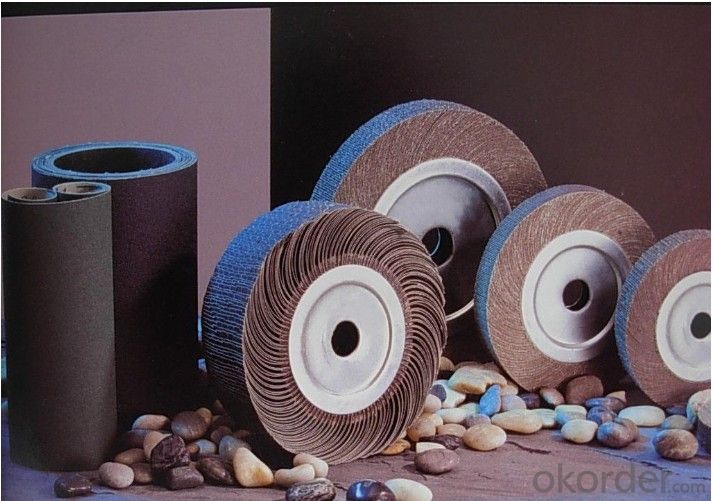

Abrasive Sanding Mesh Screen is made of nylon fabric, coated with abrasive materials; there are three kinds of shape: Sheets, Discs and Rolls.It is not only suitable for sanding plaster and wall surface, but also for sanding rusty spots of metal materials and making grinding and polishing treatment. It has good properties of grinding, cutting and filings removing. And it is the most ideal abrasive tool for interior decoration.

2.Main Features of Abrasive Sanding Mesh Screen:

High grinding efficiency, fine functioning in chip removal, excellent water tolerance and long service life

Has excellent performances of grinding, cutting and filings removing.

Being coated with abrasive materials on each side, both sides of the screens can be used

Sanding Surface of woodworking, plaster metal, plastic, enamel and remove rusty and making grinding and polishing treatment.

Easily cleaned by water, dried by air for reuse

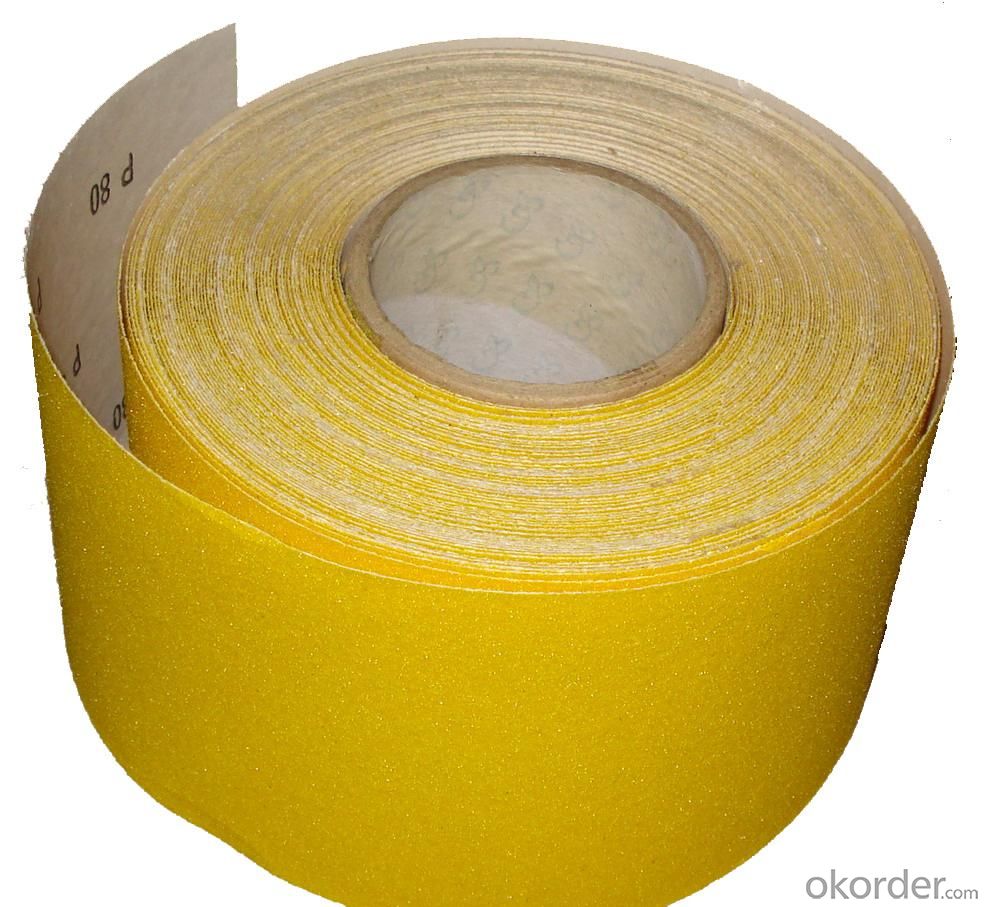

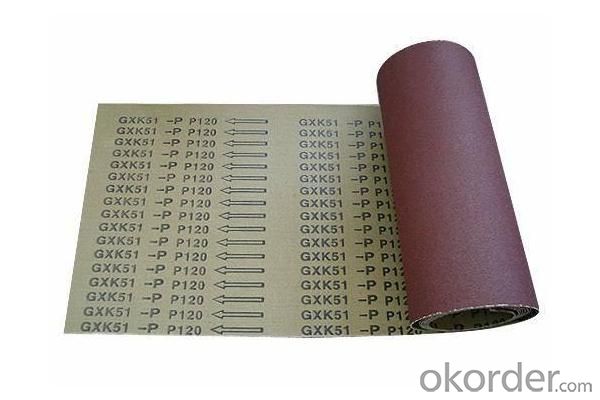

3. Abrasive Sanding Mesh Screen Images

4. Abrasive Sanding Mesh Screen Specification

| Abrasive Sanding Mesh Screen | |

| Backing | Fiberglass mesh |

| Abrasive | Silicon carbide, aluminum oxide |

| Color | Red, green, blue, white, yellow, black ,etc |

| Material | Fibreglass |

| Coating style | Close coated |

| Max width | according to customer requirements |

| Waterproofness | Good, can use wer or dry |

| Finished Shape | Sheet |

| Roll | |

| Disc | |

| Grit Range | P40-P600 |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What's the use of fiberglass mesh?

- Main performance and characteristics:1 、 good chemical stability. Alkali resistance, acid resistance, water resistance, cement corrosion resistance, and resistance to other chemical corrosion; and resin adhesion, soluble in styrene and so on.2, high strength, high modulus, light weight.3, good dimensional stability, stiffness and smooth, not easy to deformation, shrinkage of.4 、 good shock resistance. (because of high mesh strength and good toughness)5, mildew change, pest control.6. Fire protection, heat preservation, sound insulation and insulation.

- Q: The difference between alkali resistant mesh fabric emulsion and urine glue 7.5

- The mesh fabric is soft and positioned, and also folded, both of which are the common products of the exterior wall insulation.For positioning glass fiber mesh cloth glue, we do not know is not the use of adhesive to fix, in fact, glass fiber mesh cloth itself with a certain amount of binder, binder general alkali resistant glass fiber mesh is used in milkLiquid coating stereotypes, and no alkaline, usually use urine gum for coating treatment, stereotypes are almost the same effect,The effect of the coating is only too hard, so it is brittle, and sometimes it breaks easily.

- Q: What kind of wall fabric is covered with fiberglass mesh? Do you apply the powder or the powder? Thank you

- The interior powder is usually used at the joint of the wall (there is a mesh fabric specially used for joint, called adhesive tape or joint tape)

- Q: How to fill the sample size of glass fiber mesh cloth, fill what general specifications

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion.

- Q: Glass fiber mesh cloth bent do to straighten it?

- But the pot of gold coated latex products, the product is soft and hard to control, but also hard to control in a certain range, too soft or strong are not conducive to the construction, to ensure positioning under the condition of hardware and software products in the certain extent is too hard to adjust, very bad hair net, with mortar to live, because the hard product itself has a certain degree of tension, so the network control is not good, not soft products in the construction cannot be caught, so soft and hard to moderate, very convenient construction and good positioning of the product, as long as the use of mortar with trowel with live on the line, if the location is not good, with a trowel wipe when the line will return, affect the insulation effect and effect of the overall construction.

- Q: What is the function of the wall cloth mesh?

- Wall mesh, also called glass fiber wall mesh, with alkali or alkali glass fiber yarn, woven glass fiber mesh to the substrate, and then a new alkali resistant products coated with acrylic copolymer solution after drying into.

- Q: What harm does fiberglass mesh have to people?

- Into the digestive system, may cause digestive diseases.

- Q: Self making method and formula of glass fiber mesh cloth shaping glue

- The inner wall heat preservation alkali resistant glass fiber net is made of alkali or alkali free glass fiber mesh cloth as base material, and then modified by coating acrylic ester copolymer liquid. It has the characteristics of light weight, high strength, temperature resistance, alkali resistance, waterproof, corrosion resistance, anti cracking and dimensional stability. It can effectively avoid the surface tension, shrinkage and cracking caused by external forces of the plastering layer, and the light mesh cloth is often used for wall renovation and internal wall insulation.

- Q: What are the fiberglass mesh fabric manufacturers?

- Offiberglass self-adhesive caulkingGlass fiber self-adhesive tapes are made from high quality glass fiber fabric coated with acrylic copolymer, which is stable and difficult to oxygen because of its chemical propertiesSo, we developed production offiberglass self-adhesive caulking is not only superior to other similar products There is nothing comparable to this.

- Q: What is the quota of alkali resistant fiberglass mesh cloth sleeve?

- 5 thick wall plastering mortar is pressed into the middle layer of alkali resistant glass fiber mesh, 03 quota is not suitable to apply the quota items, should set their own preparation of the quota items.

Send your message to us

High Quality 550C Abrasive Sanding Mesh Screen - Fiberglass Mesh Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords