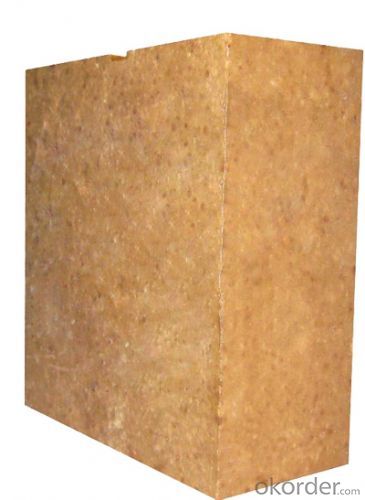

High Alumina Brick - 75%-80% Al2O3 for Steel Ladle Linings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 800000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shanxi, China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 0 | Al2O3 Content (%): | 55-80 | MgO Content (%): | 0 |

| CaO Content (%): | 0 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0 |

| SiC Content (%): | 0 | Model Number: | CL-55 CL65 CL75 CL80 | Brand Name: | CNBM |

| AL2O3: | 55-80% |

Packaging & Delivery

| Packaging Details: | ABOUT 1MT WOODEN PALLET |

| Delivery Detail: | WITHIN 45DAYS |

Specifications

High Alumina Bricks for Steel Ladle Linings

AL2O3:55-80%

ISO9001-2008

HIGH ALUMINA BRICKS FOR STEEL LADLE LININGS | ||||||

Goods Brand | CL-55 | CL-65 | CL-75 | CL-80 | PZCL-78 | |

Al2O3(%) min | 55 | 65 | 75 | 80 | 78 | |

Refractriness under load 0.2 Mpa ( °C) min | 1470 | 1490 | 1510 | 1530 | 1550 | |

Apparent porosity (%) max | 22 | 28 | 28 | 24 | 21 | |

Cold Crushing strength (MPa)min | 45 | 35 | 40 | 50 | 70 | |

Shrinkage after reheating (%) max | 1450°Cx2h | 0.1~0.5 | *** | *** | *** | *** |

1500°Cx2h | *** | 0.1~0.5 | 0.1~0.5 | *** | *** | |

1550°Cx2h | *** | *** | *** | 0.1~0.5 | 0.4~0.3 | |

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- The other is in large enterprises and individual has the unique advantage of the small enterprises, with independent technology system, production equipment advanced, there are certain funds set up to deal with risk, timely reform, such enterprises compared to a few years ago the productivity and sales or have declined, but overall is still in the stage of production increased steadily.

- Q: What are the grades of high alumina bricks?

- High alumina brick according to the aluminum content is generally divided into: super high alumina brick, a high aluminum brick, two high alumina brick, three high alumina brick

- Q: What is the price of the latest thermal insulation material?

- There are many kinds of insulation materials, and the price will fluctuate with the market. Small quantities of inquiry or procurement, then go directly to the local thermal insulation market, a wide variety of prices are basically the market price.

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- High alumina refractory brick in all thermal shock properties except performance are better than clay refractory brick, masonry in furnace and thermal equipment, such as clay bricks can be competent the work environment is not high aluminum brick masonry.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- 1. The shell of the furnace is welded by section steel and steel plate. 2, the furnace cover support adopts steel and guide rail combination mobile type. 3. The heating element is made of high resistance alloy 0Cr25Al5 produced by Beijing Shougang Group and arranged on the furnace side. 4, because the bottom bearing adopts high aluminum bricks, the circle center of the furnace set small, inside and outside heating. 5 、 furnace cover adopts hydraulic lifting, motor control, automatic walking. 6 、 temperature control system adopts PID SCR control, high accuracy.

- Q: What are the alloy wear resistance materials?

- According to the composition of Beijing Naimo metal materials company will wear resistant metal materials is divided into the following five categories: one: high manganese steel series: high manganese steel (ZGMn13),

- Q: What are the specifications for bricks?

- Thecompressive node as a new type of building energy-saving wall materials, which can be used for masonry walls, but also has good thermal properties, in line with the construction of the building module, reduce the loss in the process of construction, improve work efficiency; the hole rate reached more than 35%, can reduce the weight of the wall, save the foundation engineering cost. Compared with common sintered porous brick, it has the characteristics of heat preservation, heat insulation, light weight, high strength and high construction efficiency. The product is made of shale as raw material. It is produced by high vacuum extrusion molding machine and one yard firing process

- Q: What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- When the high alumina brick is used at high temperature, the physical and chemical indexes and other constants will not change if the temperature is in the physical and chemical indexes and the softening temperature of the load.

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- The gas will directly lead the dome combustion, in order to ensure good mixing, complete combustion of gas and air in a short time, the combustion capacity of short flame or flameless combustion burner, commonly used for semi jet short flame burner.

Send your message to us

High Alumina Brick - 75%-80% Al2O3 for Steel Ladle Linings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 800000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords