6 Oz Woven Geotextile Fabric Silt Fence/Landscape with 100gram

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Landscape Fabric Description:

Weed Barrier fabric is made of environmentally friendly raw materials, pp spunbond nonwoven fabric. It used to prevent the growth of weed, without the use of potentially dangerous chemical sprays or labor intensive hoeing. Once installed, weed mat will continue providing protection for years without maintenance.

2. Landscape Fabric Functions and Features:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

3. Weed Barrier Fabric Applications:

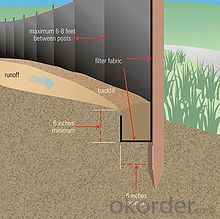

1. Weed block for landscaped garden beds

2. Permeable liners for planters (stops soil erosion)

3. Weed control under wooden decking

4. Geotextile for separating aggregate / soils under walkway blocks or bricks

5. Assists in preventing paving from settling unevenly

6. Landscape fabric prevents soil erosion

3.. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Are geotextiles suitable for use in wetlands?

- Yes, geotextiles are suitable for use in wetlands. They are commonly used to stabilize soil and prevent erosion in wetland areas. Geotextiles provide effective filtration, drainage, and separation, while also allowing water and nutrients to flow through. Additionally, they are eco-friendly and do not harm the natural habitat of the wetlands.

- Q: What are the applications of geotextiles in geotechnical engineering?

- Geotextiles have numerous applications in geotechnical engineering, including soil stabilization, erosion control, drainage systems, and filtration. These versatile materials can be used to reinforce weak soils, prevent soil erosion on slopes, and improve the overall stability of various structures, such as roads, embankments, and retaining walls. Additionally, geotextiles can act as filters to separate different soil layers, allowing for proper water drainage and preventing clogging. Overall, geotextiles play a crucial role in enhancing the performance and longevity of geotechnical projects.

- Q: How do geotextiles contribute to the stability of landfill slopes?

- Geotextiles contribute to the stability of landfill slopes by providing reinforcement and erosion control. They are placed between the different layers of soil or waste materials in the landfill, acting as a barrier to prevent soil erosion and the loss of landfill materials. The geotextiles also help to distribute loads across the slope, increasing its overall stability and preventing slope failures. Additionally, they improve drainage by allowing water to pass through, reducing the risk of pore water pressure buildup which can further destabilize the slope.

- Q: 400g / m2 two cloth a layer of water permeable geotextile technical requirements

- Two cloth a film will not be permeable, the composite film index breaking strength 5kn top broken 1.1kn tear 0.15kn peel 6n / cm or substrate fracture without stripping, the current 2008 standard weight has not been required, the original standard For not less than 360 grams

- Q: How do geotextiles affect soil temperature?

- Geotextiles can have varying effects on soil temperature depending on their characteristics and application. They can act as a barrier, reducing heat transfer between the soil and the surrounding environment, leading to lower soil temperatures. However, they can also act as an insulator, trapping heat and raising soil temperatures. The specific impact on soil temperature will depend on factors such as the material composition, thickness, color, and placement of the geotextile.

- Q: What are the considerations for geotextile selection in shoreline erosion control?

- When selecting geotextiles for shoreline erosion control, several considerations need to be taken into account. These include the type of shoreline, the severity of erosion, the desired lifespan of the solution, the presence of waves or currents, the sediment type, and the environmental conditions. Factors such as geotextile strength, permeability, durability, and resistance to UV degradation and chemical exposure should also be considered to ensure an effective and long-lasting solution for shoreline erosion control.

- Q: How do geotextiles improve the performance of shorelines?

- Geotextiles improve the performance of shorelines by providing erosion control, stabilizing the soil, and enhancing drainage. They act as a barrier that prevents soil erosion and helps to retain sediment, reducing the impact of waves and currents on the shoreline. Geotextiles also improve the stability of the soil by distributing the load and reducing the effects of settlement. Additionally, they enhance drainage by allowing water to pass through, preventing the buildup of hydrostatic pressure that can further damage the shoreline.

- Q: Can geotextiles be used in oil and gas industry applications?

- Yes, geotextiles can be used in various oil and gas industry applications. They are commonly used in areas such as erosion control, filtration, dewatering, and soil stabilization. Geotextiles can help prevent soil erosion, protect pipelines from damage, and provide reinforcement in construction projects. They are versatile and cost-effective materials that offer numerous benefits in the oil and gas industry.

- Q: What are the key considerations for geotextile installation in seismic retrofitting projects?

- Some key considerations for geotextile installation in seismic retrofitting projects include selecting the appropriate type and strength of geotextile material, ensuring proper placement and anchoring of the geotextile, evaluating the stability and drainage requirements of the site, and considering the compatibility of the geotextile with other materials and construction methods used in the retrofitting project. Additionally, careful attention should be given to the design and installation of the geotextile to ensure it effectively enhances the overall stability and performance of the structure during seismic events.

- Q: What are the different geotextile durability testing standards?

- There are several different geotextile durability testing standards, including ASTM D4355, ISO 12956, and ISO 12236. These standards evaluate the durability and performance of geotextiles by subjecting them to various mechanical, chemical, and environmental tests.

Send your message to us

6 Oz Woven Geotextile Fabric Silt Fence/Landscape with 100gram

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords