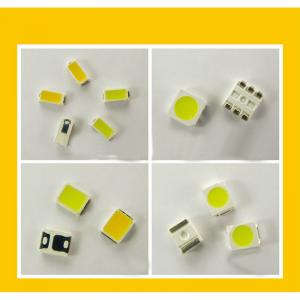

3014 SMD LED Component SMD Wholesale

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 100000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

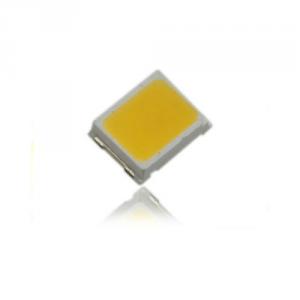

3014 SMD LED Component

1.VF:3.0-3.6V

2.Power:0.1W

3.Brightness:9-10lm/10-11lm

4.ISO9001 factory

3014 SMD LED Component

3014 SMD LED Component Features:

ABSOLUTE MAXIMUM RATING (Ta=25°C)

Item | Symbol | Value | Unit |

Peak Forward Current | IFp | 60 | mA |

Reverse Voltage | VR | 5.0 | V |

Continuous Forward Current | IF | 30 | mA |

Operating Temperature | Topr | -40 to 85 | °C |

Storage Temperature | Tstg | -40 to 100 | °C |

Lead Soldering Temperature | Tsol | 260°C For 3 Seconds | |

CHARACTERISTICS (Ta=25°C)

Parameter | Condition | Symbol | Min | Typ | Max | Units |

Power Dissipation | IF=30mA | Pd | - | 100 | - | mw |

Correlated Color Temperature | IF=20mA | CCT | 5000 | / | 8000 | K |

Forward Voltage | IF=20mA | VF | 2.8 | 3.2 | 3.8 | v |

Reverse Current | VR=5V | IR | / | / | 10 | μA |

Chromaticity Coordinates | IF=20mA | X | / | 0.31 | / | |

Y | / | 0.327 | / | |||

Luminous Flux | IF=20mA | φv | 5 | / | 9 | LM |

Luminous Flux | IF=30mA | φv | 7 | / | 13 | LM |

Color Rending Index | IF =20mA | CRI | / | 70 | / | Ra |

Full Viewing Angle | IF=20mA | 2θ1/2 | / | 120 | / | deg |

REMARK:1:1

Date | 2012-10-19 | Page | 1/1 | Model No. | SD3014WN | CHECKED |

|

REV No. |

A/0 |

Document No. |

1903014001 |

CUSTOMER |

|

APPROVED | Yucheng |

NOTE:

Testing tolerance: VF±0.1V, IV(Φv) ±10%, 2θ1/2±10% ,CCT(λD)±15%;

3014 SMD LED Component Application:

Indoor and outdoor lighting ,outdoor billboard, traffic lighting,car lighting ,LCD backlight portable and mobile lighting as flashlight , emergency lighting,and led dest lamp

- Q: What determines the brightness of the patch LED?

- The brightness is consistent over a short period of time, that is, only by considering current and voltage consistency.Long term brightness is consistent with the consideration of the spacing and heat dissipation of different circuits. Uneven heat can also affect brightness.

- Q: Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- If you choose the brightness of blue light in the light of the relatively high, so when debugging the white balance (by changing the resistance to change the current, and then change the RGB brightness LED lamp), it is difficult to transfer to the pure white. Therefore, when selecting the lamp, the blue light is generally not bright.

- Q: Indoor full color LED display module and LED what is the difference between a full color?

- Indoor full color LED display module and LED chip has three full color difference. The first part: Second: third light emitting display module: maintenance: LED full color display is not easy to maintain. LED full color patch is relatively easy to maintain.

- Q: How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

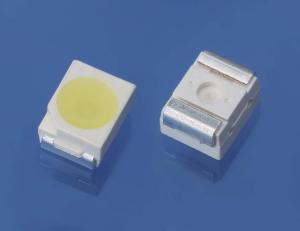

- The light emitting diode is fixed regardless of color. The light emitting diode 1, line: foot length is positive, the negative is short. The electrodes inside the tube can also be carefully observed, while the smaller ones are positive and the large ones, similar to the bowl, are negative. 2, SMD: overlooking the side with the color line is negative, the other side is positive.

- Q: LED light SMD LED package in what form, trouble you under the guidance of...

- There are 3 types of LED packages: inline LED, piranha LED, and surface mount LED

- Q: Patch LED market conditions

- Chinese suppliers also offer mature, but less profitable two-color and trichromatic products, which are mostly used in backlighting, appliances, consumer products, consumer electronics and display. Despite low market demand, vendors continue to offer sideview SMD LED, including 335 (4008), 020 (3806) and 215 (2810)

- Q: The quality of the LED patch module

- Chip manufacturers, the top chip mainly from the United States, Germany, Japan and South Korea and so on. But on the mainland LED module manufacturers to use the vast majority of chip from Taiwan, of course, there are a lot of use of chip, market positioning, the main users of the product features with the manufacturers and government policies, different chip manufacturers are different its stable performance. Maybe you will ask why not CREE, OSRAM, Nichia, first of the world's top chip manufacturers have fixed target market positioning, such as defense orders, and said, specially import a little CREE chip manufacturing module, it is also not cost-effective; and if the driver is not supporting the raw materials, it can not be completely play the advantage, so is also a great waste.

- Q: Patch LED light broken one, short circuit can use it?

- Only when a constant current source is used, the LED in series can be shorted. For the shunt power supply shunt LED, the open circuit LED can be disabled without having to manage it. The short circuit must be removed

- Q: SMD LED lamp working voltage?

- Single chip of 1 watts, more than a lot, different colors, the voltage will be different. White is usually 3.0-3.6V.* in addition to their working voltage, working current is more important parameters, once the flow, it will burn out.The LED lamp. With chips is variety, many tricks, they can be connected in series and parallel. The voltage is divided into high voltage, low voltage and medium voltage

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- First of all, welding LED and other electronic products with line electrostatic ring, to prevent static light.When welding the patch LED lamp, first add the tin on the pad of the lamp board, then clamp the LED patch lamp with tweezers. Then, the soldering iron will melt the tin of the solder plate of your lamp board, and then push the LED lamp onto the pad with tweezers. The whole welding process should not exceed 5 seconds, otherwise it will burn the lamp easily.

Send your message to us

3014 SMD LED Component SMD Wholesale

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 100000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords