2015 Astm 1320, Aisi 4140 Alloy Steel Bar And Alloy Steel Rod

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

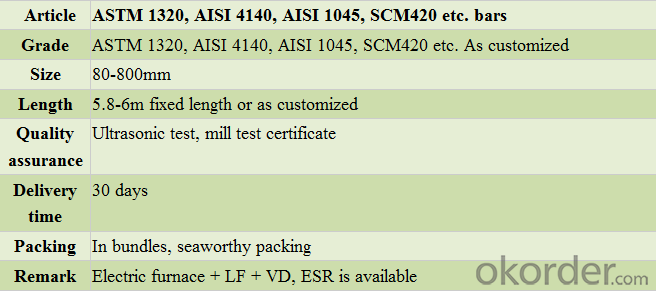

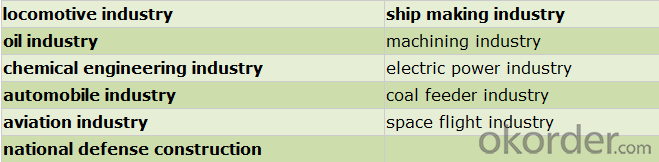

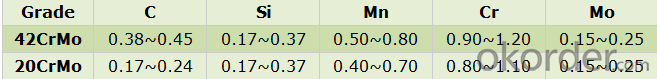

Specification

2015 Astm 1320, Aisi 4140 Alloy Steel Bar And Alloy Steel Rod

Product information

1. Produce Standard: GB, AISI, ASTM, SAE, EN, BS, DIN, JIS

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment: Normalized / Annealed / Quenched+Tempered

4. Quality assurance: All order we can received third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product detail

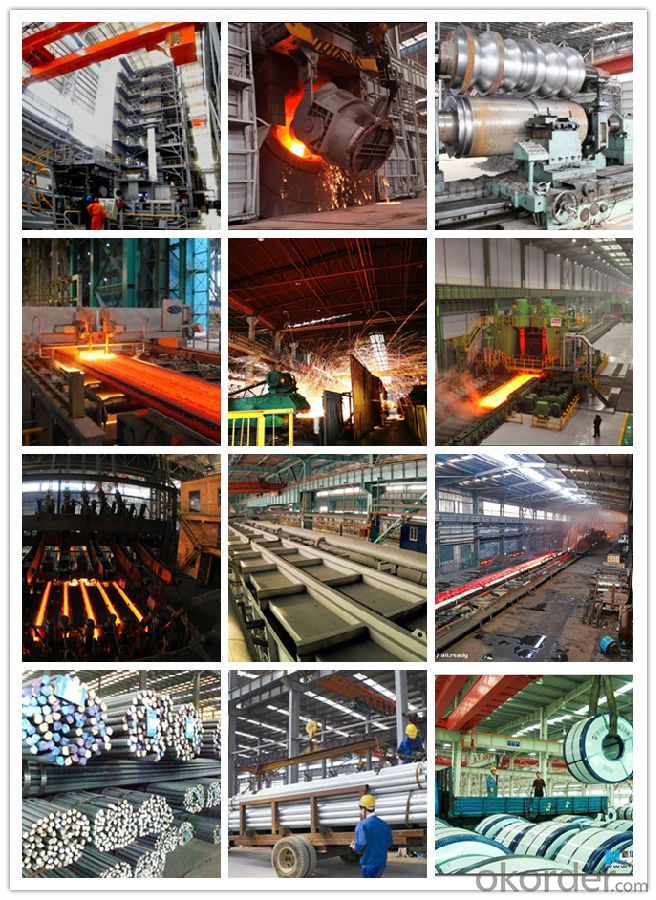

Product show

Work shop

Our Services

* Welcome to contact us with your detailed inquiry, you will be replied within 24 hours.

* You are promised to obtain the best quality, price and service.

* We'd like to provide samples for your confirm.

- Q: What are the different coating materials used for special steel?

- There are several different coating materials that are commonly used for special steel. Some of these include zinc, aluminum, nickel, and various types of polymer coatings. These coatings are applied to the steel to provide protection against corrosion, improve aesthetics, enhance wear resistance, or facilitate better adhesion for subsequent paint applications. The choice of coating material depends on the specific requirements and intended use of the special steel.

- Q: How does special steel perform in high-pressure applications?

- Special steel performs exceptionally well in high-pressure applications. This type of steel is specifically designed to withstand extreme pressure conditions, making it an ideal choice for industries that require reliable and durable materials for their operations. One of the key characteristics of special steel is its high tensile strength, which allows it to handle immense pressure without deformation or failure. This strength is achieved through alloying elements and heat treatment processes that enhance the steel's structural integrity. As a result, special steel can withstand the intense forces exerted on it in high-pressure environments, ensuring the safety and efficiency of the equipment or structures it is used in. Furthermore, special steel exhibits excellent resistance to corrosion and oxidation, further enhancing its suitability for high-pressure applications. This resistance helps maintain the structural integrity of the steel, preventing any weakening or degradation that could compromise its performance under pressure. Additionally, special steel's resistance to corrosion ensures that it can withstand harsh environments, such as those found in oil and gas extraction, chemical processing, or power generation industries. Another advantage of special steel in high-pressure applications is its ability to retain its mechanical properties even at elevated temperatures. This property is crucial in industries where high temperatures are involved, such as aerospace, nuclear power, or steam generation. The steel's high-temperature strength and stability enable it to withstand the combination of high pressure and elevated temperatures, ensuring reliable performance and long-term durability. In summary, special steel is an excellent choice for high-pressure applications due to its high tensile strength, resistance to corrosion and oxidation, as well as its ability to maintain its mechanical properties at elevated temperatures. Its exceptional performance in these demanding conditions makes it a reliable and durable material for industries that operate under high-pressure environments.

- Q: Can special steel be used in the appliance manufacturing industry?

- Yes, special steel can be used in the appliance manufacturing industry. Special steels, such as stainless steel or high-strength steel, offer various advantages such as corrosion resistance, durability, and enhanced mechanical properties. These qualities make them suitable for manufacturing appliances that require high performance, such as refrigerators, ovens, or washing machines. Additionally, special steels can be customized to meet specific design requirements and can contribute to the overall aesthetic appeal of the appliances.

- Q: How is special steel used in the construction manufacturing process?

- Special steel is commonly used in the construction manufacturing process due to its unique properties such as high strength, durability, and resistance to corrosion. It is used for various applications, including structural components, reinforcement bars, and fasteners. Special steel enhances the overall structural integrity of buildings, bridges, and other construction projects, ensuring their longevity and safety.

- Q: What are the magnetic properties of special steel?

- Special steel can exhibit a range of magnetic properties depending on its composition and processing. It can be non-magnetic, weakly magnetic, or strongly magnetic. The specific magnetic properties of special steel can be tailored to meet specific requirements for different applications.

- Q: What is the role of carbon in special steel?

- The role of carbon in special steel is to enhance its strength and hardness by forming strong chemical bonds with iron atoms, resulting in a material that is more resistant to wear and deformation. The carbon content in special steel can be carefully controlled to achieve specific properties, such as high tensile strength or improved machinability, making it a crucial element in the production of high-performance steel alloys.

- Q: How does special steel perform in high-temperature oxidation resistance?

- Special steel is specifically designed to have excellent high-temperature oxidation resistance. It is able to withstand prolonged exposure to high temperatures without undergoing oxidation, ensuring its structural integrity and performance are maintained even in extreme conditions.

- Q: What are the specific requirements for special steel used in nuclear applications?

- To ensure the suitability and safety of special steel used in nuclear applications within the demanding nuclear environment, specific requirements must be met. These requirements are designed to maintain the integrity and performance of the steel under various conditions, including extreme temperatures, radiation exposure, and corrosive environments. One primary requirement for special steel in nuclear applications is its need for high strength and toughness. The steel must possess exceptional mechanical properties to withstand the immense pressure and stress it will encounter during operation. This enables the steel to resist deformation, cracking, and failure, ensuring the structural integrity of nuclear components. Another critical requirement is the ability to withstand high temperatures and thermal cycling. Nuclear reactors operate at elevated temperatures, and the steel must retain its mechanical properties even under extreme thermal conditions. This prevents any degradation or loss of strength that could compromise the safety and efficiency of the nuclear system. Furthermore, special steel used in nuclear applications must exhibit exceptional resistance to corrosion and oxidation. The nuclear environment can be highly corrosive due to the presence of various chemicals and coolants, such as water, steam, and coolant gases. The steel must possess a high level of corrosion resistance to prevent any degradation or material loss, which could lead to leaks or failures. Radiation resistance is also a critical requirement for special steel used in nuclear applications. Nuclear reactors emit ionizing radiation, which can damage the structure and properties of conventional materials. Therefore, the steel must have a high resistance to radiation-induced embrittlement and degradation, ensuring its long-term performance in a radioactive environment. Additionally, the steel used in nuclear applications must comply with strict quality control and certification standards. These standards ensure the traceability, material composition, and manufacturing processes of the steel, guaranteeing its reliability and compliance with regulatory requirements. Quality control measures include non-destructive testing, ultrasonic examinations, and material certification. Overall, the specific requirements for special steel used in nuclear applications encompass high strength, toughness, thermal stability, corrosion resistance, radiation resistance, and adherence to stringent quality control standards. Meeting these requirements is crucial to ensure the safe and reliable operation of nuclear systems while mitigating potential risks associated with the nuclear environment.

- Q: How does special steel contribute to the renewable energy conversion efficiency?

- Special steel plays a crucial role in improving the renewable energy conversion efficiency by offering enhanced mechanical properties, corrosion resistance, and temperature resistance. It is used in the manufacturing of various renewable energy components such as wind turbine blades, solar panels, and hydroelectric power systems. The strength and durability of special steel ensure that these components can withstand harsh environmental conditions, resulting in increased efficiency, reliability, and lifespan. Additionally, special steel's high thermal conductivity allows for efficient heat transfer in concentrated solar power plants, further optimizing energy conversion.

- Q: What are the main challenges in welding special steel?

- The main challenges in welding special steel typically include issues such as high heat input requirements, susceptibility to cracking, and the need for precise preheating and post-weld heat treatment. Additionally, the presence of alloying elements in special steel can make it more difficult to achieve the desired mechanical properties and require careful selection of filler materials.

Send your message to us

2015 Astm 1320, Aisi 4140 Alloy Steel Bar And Alloy Steel Rod

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords