1/8 Aluminum Strips - Quality China Prepainted/Printed Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

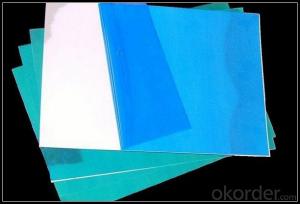

Our mill can produce all kinds of color pe pvdc painting aluminum coils ,which is used for build roof sheets:

1.Usually materials is:Alloy A3003H24 A3003H26 A3003H12 A3004H24 A3003h26

With thickness:0.6mm 0.7mm 0.8mm 0.9mm1.0mm

With width:22-1600mm

Color:according to customer

Coating:PE coated 25-28 Micro

Plastic film:0.05 or 0.06 mm film covered on the surface,could with customers' logo

Package:With inner-diameter 405mm or 505mm ,durable package for transport on sea,or as per required

.

2.specification: color pe pvdc painting aluminum coils

| Product | prepainted aluminum coil/printed aluminum coil |

| Thickness | 0.2mm-4.0mm |

| Popular Thickness | 0.25mm/0.3mm/0.4mm/0.45mm/0.5mm/0.6mm/0.9mm/1.0mm/2.0mm... |

| Width | under 1700mm |

| Popular size of sheet | 1000*2000,1200*2400,1219*2438,1220*2440 1000*3000,1250*3000,1500*3000 etc. |

| weight | about 2000kg |

Material | 1050,1060,1100,3003,3004,3105,5052,5005, 5754,5083,6061,6063 etc |

| Temper | O,H12,H14,H16,H18,H24,H26, H32,H34,H111,H112,T3,T5,T6 etc |

| Inner Diameter | 505mm |

| Color | white, gray ,gold ,blue,red,etc.(as per customer’s requirement) |

| Total coating thickness | PVDF coating: more than 25micron PE coating : more than 18 micron |

| Packing | Export standard wooden pallets (as per requirements) |

| Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

| Minimum Order Quantity | 5 tons per size |

| Delivery time | 20-30days after receiving L/C or deposit |

| Loading Port | Qingdao China (any port in China ) |

| Application | Lighting, printing, packing, decorative, electronics surface, ect. |

| Remark | Specific requirement of alloy grade,temper or specification can be discussed at your request |

3.Features: color pe pvdc painting aluminum coils

1) Super peeling strength

2) Excellent surface flatness and smoothness

3) Superior weather, corrosion, pollutant resistance

4) Even coating, various colors

5) Fireproof, excellent heat and sound insulation

6) Superior impact resistance

7) Lightweight and easy to process

8) Easy to maintain

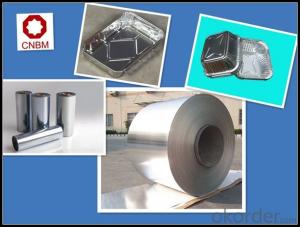

4.Application: painted polyester aluminium foil/pe coating aluminium foil

1) Building exterior curtain walls

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels

7) Industrial materials, materials for vehicles and boats

features

- Q: What benefits can be gained from incorporating aluminum strips in construction projects?

- <p>Aluminum strips offer several advantages in construction, including high strength-to-weight ratio, which means they are strong yet lightweight. They are also resistant to corrosion, making them suitable for outdoor applications and harsh environments. Aluminum strips are easy to work with, allowing for easy installation and customization. They are also energy-efficient, as they reflect heat and can help reduce cooling costs. Additionally, aluminum is recyclable, contributing to sustainability and reducing waste.</p>

- Q: What characteristics of aluminum strips make them ideal for construction purposes?

- <p>Aluminum strips are suitable for use in construction due to several key properties. They are lightweight, which reduces the load on structures and makes them easier to handle and install. They possess high strength-to-weight ratio, ensuring durability and resistance to deformation. Aluminum strips are also corrosion-resistant, protecting against rust and other forms of decay, which is crucial for long-term structural integrity. Their excellent thermal conductivity aids in heat management, which is beneficial in both heating and cooling applications. Furthermore, aluminum strips are malleable and can be easily shaped and bent, allowing for versatile design and construction. Lastly, they are recyclable, contributing to sustainability and reducing environmental impact.</p>

- Q: What types of aluminum strips are known for their durability and longevity?

- <p>Yes, there are several types of aluminum strips known for their durability and longevity. These include 3003-H14, 5052-H32, and 6061-T6 aluminum alloys. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for applications requiring high durability. 5052-H32 offers good strength, corrosion resistance, and weldability, suitable for marine and structural applications. 6061-T6 is valued for its high strength-to-weight ratio and is commonly used in aerospace and automotive industries where long-lasting performance is crucial. Proper surface treatments and coatings can further enhance the durability and longevity of aluminum strips.</p>

- Q: How much is the small aluminum belt excavator?

- Small crawler excavator about the weight and its model similar to it, such as 55, weight is about 5000kg, 60 6000kg around, 70, 80 type are similar. Price well, domestic relatively cheap, 50 type 20 to 300 thousand, 60 type is also 380 thousand to 400 thousand, 70 type of 400 thousand to 600 thousand and 80 Komatsu seems to be the lowest 600 thousand. It's all mine. Not very clear about this market

- Q: This question asks for the various types of insulation materials that are created using aluminum strips.

- <p>Aluminum strips are used in the production of several types of insulation materials. One common type is reflective insulation, which uses aluminum's reflective properties to reduce heat transfer. This can be found in the form of foil insulation or radiant barrier insulation. Another type is aluminum foil-backed insulation, often used in HVAC systems to prevent heat loss. Additionally, aluminum is a component in some types of flexible duct insulation, providing both thermal and acoustic insulation. Lastly, aluminum is used in certain types of thermal insulation boards, which are used in construction to provide thermal resistance. These materials are valued for their durability, resistance to corrosion, and effectiveness in thermal management.</p>

- Q: What specific tools are required for the installation of aluminum strips on a roof or wall?

- <p>To install aluminum strips on a roof or wall, you generally need a few special tools. These include a measuring tape for precise measurements, a level to ensure the strips are straight, a drill for making holes, and screws or nails for securing the strips. A utility knife may be required for cutting the strips to size, and a pry bar can help with positioning. Safety equipment like gloves and goggles is also essential to protect against sharp edges and debris.</p>

- Q: Is it suitable to use aluminum strips for roofing in areas with high temperatures?

- <p>Yes, aluminum strips can be used for roofing in hot climates. Aluminum is a lightweight, durable, and corrosion-resistant material that can withstand high temperatures without degrading. It reflects heat, reducing the amount of heat absorbed by the roof, which can help keep the interior of a building cooler. Additionally, aluminum's resistance to rust and corrosion makes it an ideal choice for climates with high humidity or where there is a risk of saltwater corrosion. However, it's important to ensure proper installation and ventilation to maximize its performance and longevity.</p>

- Q: Is it possible to use aluminum strips for creating decorative accents or wall art?

- <p>Yes, aluminum strips can be used to create decorative accents or wall art. They are lightweight, durable, and come in various colors and finishes, making them a versatile material for crafting. You can bend, cut, and shape aluminum strips into different designs to suit your aesthetic preferences. Additionally, they are easy to install and can be used in combination with other materials to create unique and eye-catching wall art pieces.</p>

- Q: Is it possible to use aluminum strips for the exterior walls of a building?

- <p>Yes, aluminum strips can be used for exterior walls. They are lightweight, durable, and resistant to corrosion, making them suitable for cladding and facades. Aluminum strips can also be coated with various finishes to enhance their appearance and protect against weathering. They are commonly used in modern architecture for both aesthetic and functional purposes, offering a sleek and contemporary look while providing insulation and weather protection.</p>

- Q: Is it possible to use aluminum strips as a covering for window or door frames?

- <p>Yes, you can use aluminum strips to cover window or door frames. Aluminum is a durable and lightweight material that can provide a sleek finish to your frames. It is resistant to corrosion and weathering, making it suitable for both indoor and outdoor applications. Aluminum strips can be easily cut and shaped to fit the contours of your frames, and they can be painted or anodized to match your desired aesthetic. However, ensure proper installation to maintain structural integrity and weatherproofing.</p>

Send your message to us

1/8 Aluminum Strips - Quality China Prepainted/Printed Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords