1 1/4 PVC Pipes Sewer Water Factory Quality Plastic Pipe Fittings

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of PVC Pipe :

Material: Virgin Rigid PVC resin, no recycle material

Process: vacuum forming extrusion

Color: various colors, we can make color according to Panton card No.

Quality Standard: Smooth surface, no spot, no shrink mark, no surface quality defect.Check from cross section, homogeneous in density, good plasticizing degree, relative chemical/physical property meet customer requirement. We supply different environment protection products to meet different market requirement.

Back working procedure: precise length cutting, drilling/slotting/punching, gold stamping, quality inspection, cleaning, assembling, and packing.

2.Features of PVC Pipes :

1) Light weight, easy to load and unload: PVC pipe is very light, convenient to handle loading unloading, and installing.

2) Good chemicals and drugs resistance: PVC pipe has its excellent resistance to the erosion caused by acids and alkalines, a great help to the chemical industries.

3) Small resistance to fluidity: The smooth surface reduces resistance to the fluids. Its roughness coefficient is only 0.009, much less than other pipes, Under same discharges, smaller cabibre of the pipe can be uesd.

4) Strong mechanical strength: Good resistance to water pressure, outside impact and pressure, is satisfied under any conditions.

5) Good electrical insulation: excellent insulation nature against electricity. the pvc pipe can be served as conduits and pipes in construction cable and wire.

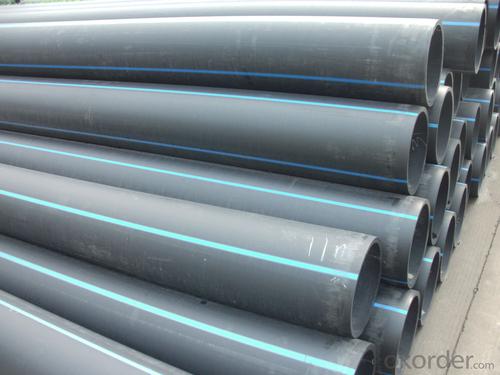

3.PVC Pipe Images:

4.Specifications of the PVC Pipe:

1) Material: pvc pipe unplasticized polyvinyl chloride

2) Standard: GB, ISO9001, ISO14001

3) Color: white pvc pipe, grey pvc pipe , etc.

4) Specific Gravity:g/cm3, 20(C): 1.35 - 1.55

5) Vicat Softening Temperature: (C) >=79

6) Dichloromethane Resistance Test: No attack

7) Falling Weight Impact Test: TIR, %, 0(C) <=10< span=""><>

8) Tensile Yield Strength: Mpa >=40

5.FAQ

Q:What is the production ability? or delivery time?

A:Our production ability support 40HQ order finish in one week.

Q:What is the regular shipping port?

A:Tianjin or Shanghai.

Q:What is your payment?

A:TT or CC.

Q:Can we have sample?

A:Sample free, freight cost you.

- Q: How do plastic pipe fittings compare to cast iron fittings?

- Plastic pipe fittings and cast iron fittings have their own advantages and disadvantages. Plastic fittings are generally more cost-effective, lightweight, and easier to install as they require fewer tools and are less prone to corrosion. They also offer good resistance to chemicals and provide more flexibility in design options. On the other hand, cast iron fittings are known for their strength and durability, making them suitable for high-pressure and high-temperature applications. They also have better sound insulation properties and are less likely to expand or contract. Ultimately, the choice between plastic and cast iron fittings depends on the specific requirements of the plumbing system and the intended use.

- Q: Can plastic pipe fittings be used in oil and gas applications?

- Yes, plastic pipe fittings can be used in oil and gas applications. Plastic materials like polyethylene and polypropylene are commonly used in these industries due to their corrosion resistance, durability, and cost-effectiveness. Plastic pipe fittings can effectively handle the pressure and temperature requirements of oil and gas systems while providing reliable performance and longevity. However, it is important to choose fittings that are specifically designed and certified for oil and gas applications to ensure safety and compliance with industry standards and regulations.

- Q: What are the manufacturing processes of plastic pipe fittings?

- Vacuum - hot melt extrusion - vacuum sizing - two spray - print traction ---- product cutting ---- visual inspection ----Package warehousing

- Q: Can plastic pipe fittings be used for fluid handling in manufacturing?

- Yes, plastic pipe fittings can be used for fluid handling in manufacturing. Plastic pipe fittings are commonly used in various industries for fluid handling due to their durability, corrosion resistance, and cost-effectiveness. They are suitable for a wide range of fluids, including water, chemicals, gases, and even some abrasive materials. Additionally, plastic pipe fittings are lightweight and easy to install, making them a popular choice in manufacturing processes.

- Q: How do plastic pipe fittings compare to CPVC fittings?

- Plastic pipe fittings and CPVC fittings have some similarities, but there are also notable differences between the two. Both types of fittings are used in plumbing systems, but CPVC fittings are specifically designed for use with CPVC pipes, which are a type of plastic pipe that can withstand higher temperatures and pressures compared to regular plastic pipes. CPVC fittings are also more resistant to chemical corrosion, making them suitable for a wider range of applications. However, plastic pipe fittings may be more cost-effective and easier to install in certain situations. Ultimately, the choice between plastic pipe fittings and CPVC fittings depends on the specific requirements of the plumbing system and the intended use.

- Q: Are plastic pipe fittings resistant to UV radiation?

- Yes, plastic pipe fittings can be resistant to UV radiation. Many modern plastic pipe fittings are specifically designed and manufactured with UV stabilizers, which help to protect them from the damaging effects of UV radiation. These stabilizers prevent the plastic from degrading, becoming brittle, or losing its structural integrity when exposed to sunlight and other sources of UV radiation. However, it is important to note that not all plastic pipe fittings are UV resistant, so it is crucial to choose fittings that are specifically labeled or specified to have this property if UV exposure is a concern.

- Q: What are the potential drawbacks of using plastic pipe fittings?

- Some potential drawbacks of using plastic pipe fittings include their susceptibility to cracking or breaking under certain conditions, limited resistance to high temperatures or extreme weather conditions, and potential for chemical reactions with certain substances. Additionally, plastic pipe fittings may have lower durability and lifespan compared to other materials, such as metal fittings.

- Q: Are plastic pipe fittings suitable for chemical transfer applications?

- Plastic pipe fittings can be suitable for chemical transfer applications depending on the type of plastic material used and the specific chemicals being transferred. Some plastic materials, such as PVC (Polyvinyl chloride) or CPVC (Chlorinated polyvinyl chloride), offer good chemical resistance and can be used for a wide range of chemical transfer applications. However, it is essential to check the compatibility of the plastic material with the specific chemicals being transferred to ensure proper performance and avoid any potential reactions or degradation.

- Q: Are plastic pipe fittings resistant to hydrocarbons and oils?

- Yes, plastic pipe fittings are generally resistant to hydrocarbons and oils.

- Q: Do plastic pipe fittings require any special insulation or lagging?

- No, plastic pipe fittings do not require any special insulation or lagging. Plastic pipes are generally resistant to heat loss, so additional insulation is not necessary. However, it is always a good practice to consult with a professional plumber or follow the manufacturer's guidelines for specific installations.

Send your message to us

1 1/4 PVC Pipes Sewer Water Factory Quality Plastic Pipe Fittings

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches