Sublimation Aluminum Sheet Stock

Sublimation Aluminum Sheet Stock Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Aluminum Foil For The Grill Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Aluminum Foil For Grow Room Aluminum Foil For Joint PainHot Searches

Stock Price For Aluminum Aluminum Coil Stock For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Aluminum Bar Stock For Sale Aluminum Round Stock For Sale Aluminum Diamond Plate For Sale Aluminum Scaffolding For Sale Craigslist 6061 Aluminum Plate For Sale Aluminum Dock Plate For Sale 7075 Aluminum Plate For Sale Aluminum Tread Plate For Sale Aluminum Checker Plate For Sale Aluminum Plate For Sale Near Me Plate Aluminum For Sale Aluminum Plate For Sale Aluminum Square Stock For Sale Aluminum Flat Stock For Sale Billet Aluminum Stock For SaleSublimation Aluminum Sheet Stock Supplier & Manufacturer from China

Okorder.com is a professional Sublimation Aluminum Sheet Stock supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Sublimation Aluminum Sheet Stock firm in China.Hot Products

FAQ

- The hardness of aluminum sheets can vary depending on the specific alloy and temper it has been processed to. Aluminum alloys are typically measured on the Rockwell hardness scale or the Brinell hardness scale. Generally, pure aluminum has a low hardness rating, around 20-30 on the Rockwell B scale, while some aluminum alloys can reach a hardness of up to 70 on the Rockwell C scale. However, it is important to note that the hardness of aluminum can be further modified through various heat treatment processes, such as annealing or tempering, which can significantly impact its final hardness.

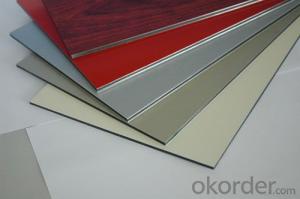

- There are several types of surface treatments available for anodized aluminum sheets, including polishing, brushing, sandblasting, etching, and coloring. Each treatment option provides a unique aesthetic and functional finish to the aluminum surface.

- Indeed, aluminum sheet is suitable for food contact applications. The food industry extensively utilizes aluminum owing to its exceptional characteristics. It is non-toxic, resistant to corrosion, and possesses a high thermal conductivity, rendering it appropriate for an array of food processing and packaging purposes. By utilizing aluminum sheets, one can craft food containers, trays, and foils, thereby offering a secure and sanitary solution for storing and transporting food. Moreover, aluminum is recyclable, making it an environmentally conscious selection for food contact applications.

- Certainly, aluminum sheets are capable of being polished. Aluminum, being a relatively malleable metal, lends itself to easier polishing in comparison to harder metals like stainless steel. The act of polishing aluminum sheets entails the utilization of abrasive substances such as sandpaper or polishing compounds. This serves to eliminate any blemishes, scratches, or oxidation present on the surface. Typically, the process involves multiple stages of polishing, employing varying degrees of grit in sandpaper or polishing compounds. Step by step, a smoother and more reflective surface is attained. Polished aluminum sheets find common usage in various applications, including automotive components, architectural elements, and ornamental objects. The polishing process elevates the metal's aesthetic appeal, imparting a glossy and reflective finish.

- Aluminum sheets have the capability to undergo a process called aluminum sheet coating or aluminum sheet finishing, wherein they are coated with different materials. This coating process serves several purposes, such as enhancing their appearance, protecting against corrosion, increasing durability, and providing insulation. Painting, anodizing, laminating, and powder coating are among the various methods available to coat aluminum sheets. Each method offers unique advantages and is selected based on the desired outcome and intended usage of the coated aluminum sheet. Coating aluminum sheets with other materials allows for customization, versatility, and enhanced functionality in a wide range of industries, including construction, automotive, aerospace, and consumer goods.

- To prevent surface marring of aluminum sheets during handling, there are several steps you can take: 1. Use clean gloves or finger cots: When handling aluminum sheets, it is important to avoid direct contact with bare hands as they may contain oils, dirt, or other contaminants that can leave marks on the surface. Wearing clean gloves or finger cots can provide a barrier and prevent any transfer of substances onto the sheets. 2. Use protective packaging: Prior to handling, consider using protective packaging such as foam or plastic sheets to cover the surface of the aluminum sheets. This will provide an additional layer of protection against scratches or abrasions during transportation or storage. 3. Implement proper storage and handling techniques: Store aluminum sheets in a clean and dry environment, away from any abrasive materials or surfaces. When moving or handling the sheets, ensure that they are lifted or supported evenly to avoid any bending or distortion that may lead to surface marring. Using appropriate lifting equipment, such as suction cups or clamps, can help distribute the weight evenly and minimize the risk of damage. 4. Clean the surface regularly: Regularly clean the aluminum sheets using a mild detergent or aluminum-specific cleaning solution. This will help remove any dirt, grime, or other substances that could potentially cause surface marring. Be sure to use soft, non-abrasive cleaning tools such as microfiber cloths or sponges to avoid scratching the surface. 5. Implement quality control measures: Establishing quality control measures during the handling process can help identify any potential sources of surface marring. Regular inspections should be conducted to check for any signs of damage or defects. Implementing proper training for employees involved in the handling process can also help minimize the risk of surface marring. By following these preventive measures, you can significantly reduce the chances of surface marring on aluminum sheets during handling, ensuring their pristine condition and quality.

- What is aluminium plate L2-Y2?

- L2Y2 is an industrial pure aluminum sheet:1, L2: China's industrial pure aluminum grades are limited by impurities to prepare, such as L1, L2, L3...... L, is the "aluminum" word Pinyin prefix, followed by the attached order number is bigger, its purity is low. Industrial pure aluminum is generally defined as aluminum with a purity of 99% to 99.9%, and China is designated as 98.8% - 99.7% aluminum.