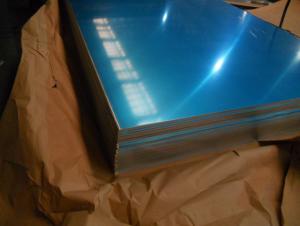

Wholesalers and Materials & Equipment Aluminium Sheet Products

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 3 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alloy & Size:

1. alloy number 1050 1060 1070 1100 1200 3003 3004 5052 8011.

2. temper available O H14 H16 H18 H22 H24.

3. thickness: 0.2- 100mm.(+/-0.02mm)

4. Width: 30-1700mm.(+/-0.5mm)

Packaging & DeliveryPackaging Detail:

1.aluminium sheet is packed in seaworthy pallet.

2.aluminium weights about two tons per pallet. W1000mm x L2000mm,

3.Size: W 1220mm x L2440mm or customer.

4.Loading: 20-22tons/20 FCL.

Delivery Detail: 20 working days

Specifications:

1.flat mill finished surface.

2.without oxidation and scratch.

3.high quaity and the best service.

Supply aluminum material five major areas of production surplus - supply aluminum material ceramic aluminum plate punching aluminum ceiling net carved Zhuang aluminum plate shaped tile corrugated plate materials products in five major areas of production capacity surplus analysis "from the beginning of 1 million tons, up to now 8 million tons, still says excess capacity, Deputy Secretary General of the China Iron and steel industry association long when subjected to" invest in China "interview said. Recently, China Steel Association released was China's steel production capacity had reached the 8 million tons, but the practice compliance of iron and steel production as long as 4 million tons, still 4 million tons production capacity not by the national approval.

Since 1999 was put on the excess capacity of the hat, the steel industry production capacity will continue to increase as demand continues to expand. On the basis of demand forecasting, the state of the steel industry capacity expansion continues to develop planning, however, due to the need to break the planning of production capacity, and thus the market's production capacity has repeatedly broken the national planning. As in 2009 the first state of the State Council, iron and steel property adjustment and ZTE planning in the prediction of China's crude steel consumption was 4.3 tons, but the actual consumption of 5.7 tons in the past. CISA estimation of crude steel consumption will reach 6.8 million tons, and was approved by the state to the iron and steel production capacity as long as 4 million tons, market is still 4 million tons of production capacity of violations will compensate for the demand gap.

Reality, aluminum material in nearly 10 years of government micro regulation, Chinese iron and steel, cement, nonferrous metals and other industries was defined as "excess capacity" industry, and is suitable for relatively serious land, taxation, project approval, and all kinds of property policy.

- Q:I need to install hand rails around a hot tub and wonder if aluminum would work well.

- It should hold up well I don't think there would be any reaction. They use aluminum railings as stairs for large pools. The aluminum might be coated with something else though. Aluminum usually forms a thin coat of Aluminum Oxide, Al2O3, so it should prevent it from further oxidation.

- Q:How do you prevent warping of aluminum sheets during machining?

- One way to prevent warping of aluminum sheets during machining is by using proper coolant or lubricants during the machining process. This helps in reducing the friction and heat generated, which can cause warping. Additionally, maintaining correct cutting speeds and feeds, as well as ensuring proper tool selection and machining techniques, can also help minimize the chances of warping.

- Q:Aluminum alloy cable tray is made of a series of aluminum sheets, a series of pure aluminum aluminum plate can do?

- Do you fold it with aluminium plate? It should be about the same. The cold rolled aluminum of the 1 series is still a little bit stronger,I understand the shape of the material, and if the aluminum extrusion molding, direct use of 6063 is the most appropriate.

- Q:can the oxide film on the surface of aluminum sheet prevent the erosion of acid liquid? Why?

- yes, acid can react with aluminum oxide , generating salt and water, but its anti-corrosion will be stronger if oxide film on the surface is enough dense.

- Q:how to avoid oxidation of aluminum sheet after wire drawing?

- leave it alone after wire drawing!aluminum sheet will formulate a layer of dense oxide film. So you don't need to worry about it! Don't often polish the aluminum wire, or they will be more and more slimsy, the oxide film is used for avoiding reoxidation.

- Q:What advantages does the ceramic panel curtain wall have compared with the aluminum sheet and stone curtain wall?

- Now, there are many kinds of ceramic curtain walls. They are made of natural clay materials. They are green, environmentally friendly, low energy consumption, and they are not easy to fade and deform. They have good corrosion resistance and durability, and high strength. At present, the domestic market of ceramic tile is faster than that of foreign countries. I heard ruigao is the first manufacturer of ceramic plate, there are other TOB ah, new Kerry ah. The strength is good.

- Q:Can aluminum sheets be used for modular construction?

- Absolutely, modular construction can utilize aluminum sheets. Aluminum proves to be an adaptable and lightweight substance that presents numerous advantages for modular construction undertakings. Its resilience, resistance to corrosion, and impressive strength-to-weight ratio render it appropriate for a wide range of structural applications. The malleability of aluminum sheets permits them to be effortlessly fabricated and molded into various forms and dimensions, enabling flexibility in both design and construction. Furthermore, aluminum's recyclability positions it as an environmentally conscious selection for sustainable construction practices. All things considered, aluminum sheets stand as a feasible choice for modular construction given their robustness, durability, and versatility.

- Q:who knows the ceiling technology of aluminum sheet?

- Different materials usually have difference in construction technology. The detailed ceiling construction technology process of aluminum buckle plate:1, snapping line: according to the elevation horizontal line of floor, designed elevation, surrounding ceiling elevation horizontal line, you can find the central point of your room. Then alone the ceiling’s elevation horizontal line, take the central point of your room as focus, you can draw the grading line of keel. 2, install main keel boom: after ensuring the ceiling’s elevation horizontal line and keel’s location line, you can measure the elevation of the below ending of boom, and install the boom processed before. You can use expansion bolt to fix the boom on ceiling. Choose round steel as boom, control the gap of hanging bar under the range of 1200mm.3, install main keel: choose C38 light steel keel as main keel, control the gap under 1200mm. connect it with fitting and boom matched with main keel while installing. 4, install side keel: fix 25×25mm coated keel on the surrounding wall with cement nail according to net height of ceiling, control the cement nail’s gap under 300mm. 5, install sub keel: install the sub keel matched with aluminum buckle plate according to the size of aluminum buckle plate, hang the sub keel on main keel through hanger. When the sub keel needs to be prolonged by several keel, use the adapting piece of sub keel, connect the two ends and fix them after straightening at the same time of hanging the sub keel.

- Q:What is the coefficient of friction for aluminum sheets?

- The coefficient of friction for aluminum sheets can vary depending on the specific conditions, such as the surface it is in contact with and the presence of lubricants or contaminants. In general, the coefficient of friction for aluminum sheets is relatively low, ranging from 0.2 to 0.6. However, it is important to note that these values are approximate and can be influenced by various factors.

- Q:What are the different types of alloys used for powder-coated aluminum sheets?

- There are several different types of alloys used for powder-coated aluminum sheets, each with its own unique set of properties and characteristics. Some of the most commonly used alloys include: 1. 3003 Alloy: This alloy is one of the most widely used for powder-coated aluminum sheets. It offers good corrosion resistance, excellent formability, and high strength. It is often used in applications that require moderate strength and resistance to atmospheric corrosion, such as building facades, signage, and automotive parts. 2. 5052 Alloy: This alloy is known for its high strength and excellent corrosion resistance. It is often used in marine and architectural applications where durability and resistance to saltwater and harsh environments are essential. It is also commonly used in the manufacturing of electrical enclosures and transportation equipment. 3. 6061 Alloy: This alloy is highly versatile and offers excellent weldability, formability, and machinability. It is often used in a wide range of applications, including aerospace components, marine hardware, structural components, and automotive parts. It has good corrosion resistance and can be easily powder-coated to enhance its appearance and provide additional protection. 4. 7075 Alloy: This alloy is known for its high strength-to-weight ratio and excellent fatigue resistance. It is commonly used in aerospace applications, such as aircraft fittings and structural components, where strength and lightweight properties are crucial. Although it is less commonly used for powder-coated aluminum sheets due to its higher cost, it can still be found in certain specialized applications. These are just a few examples of the different types of alloys used for powder-coated aluminum sheets. The choice of alloy depends on the specific requirements of the application, including factors such as strength, corrosion resistance, formability, and cost.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wholesalers and Materials & Equipment Aluminium Sheet Products

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 3 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords