Coated Aluminum Coils for Beverage Can Stock

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Coated Aluminum Coils for Beverage Can Stock

Our coated aluminium coils are widely used in beverage can stock, such as can ends, can lids, can tabs, aluminium easy-can-cover and ring-pull, etc.

We normally use 5052 H19; 5052, H36; 5182 H19; 5182 H48, 5182 H49 as base coils. Based on ordinary aluminum, we add Mn and Mg, so as to increase tensile strength and elongation.

As for coating, we normal coat gold color for lids, red, blue, etc for tabs. We also can adjust coating according to color of customers and offer personalized services.

We use large wave shear, transverse shear and longitudinal cut system so as to meet different specifications of customers.

2. Main Features of Coated Aluminum Coils for Beverage Can Stock

• Light Weight

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rustproof

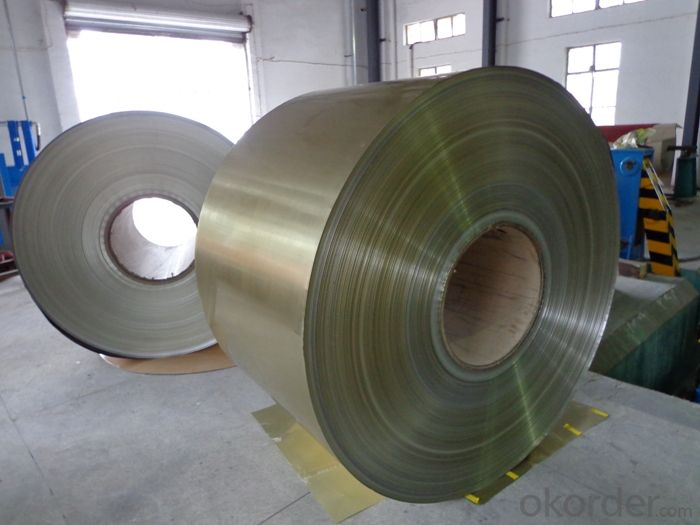

3. Coated Aluminum Coils for Beverage Can Stock Images

4. Specification of Coated Aluminum Coils for Beverage Can Stock

ALLOY | TEMPER | THICKNESS | WIDTH | COIL OR LENGTH |

5052 5182 | H19 H36 H48 H49 | 0.22-0.5mm | 500-1600mm | AS PER YOUR REQUIREMENTS |

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:metals an aluminum can is made of, cast aluminum, 6160 aluminum, sheet aluminum

- the aluminum is alloyed with various metals to change the characteristics of the aluminum the link below shows a table showing the various chemical/metals added to aluminum to make different alloys

- Q:Relevant question 5Excuse me, what's the meaning of your "deoiling effect"? And you answer two kinds of performance, my understanding is that the oil removal effect is not good, lead to aluminum volume is not neat, what is the difference between the two? Solution, thank you

- Oil removal effect is not good rolling oil remover oil extrusion is not complete, coiling in aluminum strip surface residual oil too much, after coiling because of oil coated on the aluminum coil inside played a supporting role in the beginning of aluminum roll edge round, with aluminum coil of diameter increases, the inner pressure increases.

- Q:Can aluminum coils be used for food processing conveyor systems?

- Yes, aluminum coils can be used for food processing conveyor systems. Aluminum is a durable and lightweight material that is resistant to corrosion, making it suitable for food processing environments. Additionally, aluminum is non-toxic and does not react with food, ensuring the safety and quality of the processed products.

- Q:Are aluminum coils more cost-effective compared to other materials like copper?

- Aluminum coils are generally more cost-effective than other materials like copper for several reasons. To begin with, aluminum is a more abundant metal, making it cheaper to produce. Its abundance also results in more stable prices, reducing the likelihood of market fluctuations and further enhancing its cost-effectiveness. Furthermore, aluminum coils have a lower density compared to copper coils, resulting in lighter units. This lighter weight not only reduces costs for transportation and installation but also makes them easier to handle and maneuver during the manufacturing process. In addition, aluminum coils possess excellent thermal conductivity properties, enabling efficient heat transfer. This leads to more efficient cooling or heating systems, resulting in lower energy consumption and operating costs in the long run. Moreover, aluminum exhibits higher resistance to corrosion compared to copper, making it more durable and requiring less maintenance. The longer lifespan of aluminum coils reduces the need for replacements and repairs, further contributing to their cost-effectiveness. Lastly, aluminum coils are recyclable, and the recycling process requires significantly less energy than producing new aluminum. This aspect adds to the overall sustainability and cost-effectiveness of aluminum coils. In conclusion, considering their lower production costs, lighter weight, superior thermal conductivity, increased durability, and recyclability, aluminum coils are indeed a more cost-effective option compared to materials like copper.

- Q:Normal aluminum like you find in the ground, not the man made stuff

- An interesting thing about aluminum is that when you oxidize it, it actually becomes harder and more stable, but loses its metallic propery (it's what sapphire is made of in larger crystaline form). It's found this way in nature, as aluminum oxide in feldspars and most importantly bauxite. The melting point of alumina is extremely high, however. It's mixed with other chemicals where it dissolves instead, like gold in mercury. Then the pure aluminum is later extracted. It doesn't glow in the dark.

- Q:Do you have an aluminum coil first? Is there an aluminum plate?

- The general process of aluminum plate production is: aluminium ingot - aluminum water - casting roll - aluminum roll ---- aluminum plate [Ji'nan excellent aluminum industry]. Welcome to visit.

- Q:What are the different coil edge profiles available for aluminum coils?

- Aluminum coils come with a variety of coil edge profiles. Some commonly used profiles are: 1. Slit edge: This is the most basic type, where the coil is simply slit to the desired width. The edges of the coil are usually sharp and may have burrs or roughness. 2. Deburred edge: In this profile, the sharp or rough edges of the coil are removed through deburring. Deburring enhances safety and prevents damage to downstream equipment during processing. 3. Rounded edge: This profile involves rounding the edges of the coil through rolling or machining. Rounded edges are often preferred in applications that prioritize safety or involve frequent handling of the coil. 4. Beveled edge: Beveled edge profiles are created by cutting or grinding the edges of the coil at an angle. This profile is commonly used when two coils need to be joined together, as the beveled edges enable a smoother and more secure connection. 5. Custom edge profiles: Depending on the specific requirements of the application, custom edge profiles can be developed. These profiles are tailored to meet the unique needs of the customer and may involve a combination of different edge treatments. It's important to consider the intended application, processing requirements, and desired aesthetic appearance when choosing a coil edge profile. Manufacturers and suppliers of aluminum coils typically offer a range of edge profiles to accommodate different customer needs.

- Q:What are the width tolerances for aluminum coils?

- The width tolerances for aluminum coils can vary depending on the specific application and industry standards. However, in general, the standard width tolerances for aluminum coils typically range between +/- 0.005 inches to +/- 0.020 inches. These tolerances ensure that the width of the aluminum coil falls within an acceptable range and meets the required dimensions for the intended use. It is worth noting that tighter tolerances may be achievable depending on the specific manufacturing processes and equipment capabilities. Therefore, it is essential to consult the appropriate industry standards and specifications to determine the exact width tolerances required for a particular application.

- Q:Are there any restrictions on the coil flatness of aluminum coils?

- Yes, there are restrictions on the coil flatness of aluminum coils. The industry standards specify acceptable tolerances for coil flatness to ensure the quality and usability of the aluminum coils. These restrictions help prevent any deformation or irregularities in the coils, ensuring they meet the required specifications for various applications.

- Q:A magnet will not attract a aluminum bar, but if you have an electromagnetic field made by an transformer it will interact.Why is that?Why iron is attracted and wood is not?

- Aluminum is not a magnetic material and will not be affected by stationary magnets. However, if a changing magnetic field is present, an electrical voltage will be induced in the aluminum ring and an electric current will flow as a result. This current will produce a magnetic field which will interact with the externally produced magnetic field. The key here is a changing magnetic field - because the voltage induced in the aluminum ring will be proportional to the rate of change of the field. If an aluminum disk is passed between the poles of a powerful magnet, eddy currents will be induced in the aluminum producing a magnetic field that will tend to retard the motion of the aluminum relative to the magnet. The changing field in this case is due to the motion of the aluminum. Iron is attracted to a magnetic field because it is a ferro-magnetic material. Wood is not a magnetic material, and it is not an electrical conductor, so it will not behave as aluminum does in a magnetic field.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coated Aluminum Coils for Beverage Can Stock

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords