Samsung Bespoke Stainless Steel

Samsung Bespoke Stainless Steel Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleSamsung Bespoke Stainless Steel Supplier & Manufacturer from China

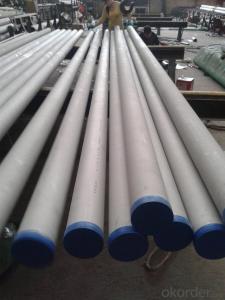

Okorder.com is a professional Samsung Bespoke Stainless Steel supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Samsung Bespoke Stainless Steel firm in China.Hot Products

FAQ

- What material is used for the screw nut of machine tools?

- As the screw rod 1 to compressive strength and fatigue resistance enough 2 has certain plasticity and toughness, low coefficient of friction and good running in 3 has good thermal conductivity, thermal expansion coefficient and corrosion resistance of low alloy, sliding bearing

- How can the accuracy of the CNC machine tools be compensated after a few years?

- Use laser interferometer to do the screw repair

- CNC machine tool screw gap

- For a pure driving situation, general requirements for flexible transmission, allow a certain return to the gap (small, usually a few silk), using a single nut, it is cheaper and more flexible transmission; for a return to the precision of gear clearance conditions is not allowed, it is required to choose double nuts, it can adjust the magnitude of pre tightening force, keep good, and can be repeatedly adjusted; in addition, restricted travel in space, also can choose the variable lead preload (commonly known as stagger preload), the pretightening force is small, and it is difficult to repeat adjustment, generally do not choose.If the gap is large, please timely maintenance, system compensation value can not be too large, in the case of large gap screw, continue to use, will greatly shorten the service life of the lead screw, and easy to cause damage can not be repaired

- How about the central screw in the CNC lathe? Or an ordinary side screw!

- Sen's advantage: cheap. Disadvantages: in addition to cheap. 6136 a little more than 5. Buy 36, buy 40, not much money. I don't know how high the power of the 36 spindle is, anyway, 40 is 5.5KW. Variable frequency spindle is more sensitive to power. Low speed, the output force is not enough, and sometimes will stop the spindle. Now that you choose big Sen, you value his merits. Well, I won't comment either. The design of the middle screw leads to the inconvenience of cutting, and no improvement has been found in the design process. Goods than three in order to find quality products, the boss, you may as well more Internet, check different machine tool factory products, learn more to earn more. I wanted to go on, but when I saw the eggs, I was really embarrassed to go on.

- I'd like to make my own lathe screw. What material should I use?

- Lathe design three bar materials are No. 45 steel.

- Is the grease of the machine tool screw rod good or weak?

- Screw rod bearings relatively high speed, should be diluted (low viscosity) of grease, with high viscosity grease will lead to increased friction, temperature rise, the result is easy to burn bearings.

- I would like to ask what method installed, do not know how many balls, loaded and loaded less, what is the situation, ah, urgent, thank you

- The first floor is right, but this way to operate, few people installed good, there are special tools for ball bearings, if the screw gap, you can replace the ball to repair. LZ I can send you a tool map if necessary. Your points are very attractive - -,