1 2 X 1 2 Aluminum Bar Stock

1 2 X 1 2 Aluminum Bar Stock Related Searches

1/2 X 3/4 Aluminum Bar Stock 2 1 2 Cast Iron Pipe 1 2 Inch Aluminum Plate 1 2 X 1 2 Aluminum Bar Stock 1/2 X 1/2 Aluminum Bar Stock 1/4 X 1/4 Aluminum Bar Stock Aluminum Bar Stock 1 2 1 1/2 Aluminum Round Stock 4 X 8 X 1 4 Aluminum Plate 1 8 X 1 Aluminum Bar StockHot Searches

Welded Wire Mesh Panels For Sale Mesh Wire For Sale Welded Wire Panels For Sale Plywood 1 2 Inch Price Cost Of 1 2 Inch Plywood 1 2 Type X Gypsum Board 1 2 Inch Type X Drywall 1 2 Type X Drywall Plywood 1 2 Inch Price Cost Of 1 2 Inch Plywood 1 2 Type X Gypsum Board 1 2 Inch Type X Drywall 1 2 Type X Drywall Welded Wire Mesh Panels For Sale Welded Wire Mesh Price Philippines Plywood 1 2 Inch Price Cost Of 1 2 Inch Plywood 1 2 Type X Gypsum Board 6X6 Welded Wire Mesh Prices 1 2 Inch Type X Drywall1 2 X 1 2 Aluminum Bar Stock Supplier & Manufacturer from China

Okorder.com is a professional 1 2 X 1 2 Aluminum Bar Stock supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 1 2 X 1 2 Aluminum Bar Stock firm in China.Hot Products

FAQ

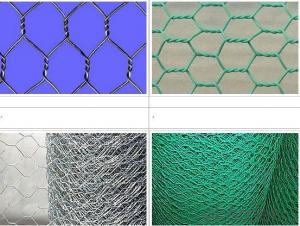

- In terms of resistance to abrasion, steel wire mesh demonstrates outstanding performance. The mesh design, which incorporates the interlocking nature and the high tensile strength of steel, contributes to its remarkable ability to withstand wear and tear resulting from rubbing or scraping against other surfaces. Consequently, steel wire mesh becomes the preferred choice for applications that necessitate durability and longevity, including construction, industrial settings, and reinforcement in concrete structures. The robust construction of the steel wire mesh guarantees its ability to endure the impact of abrasive materials and maintain its integrity throughout time, making it an exceptional alternative for environments that require crucial abrasion resistance.

- Using steel wire mesh in the chemical refurbishing industry offers several advantages: 1. Chemical Resistance: Steel wire mesh has exceptional resistance to various chemicals, acids, and corrosive substances commonly found in the industry. This resistance ensures the mesh remains intact and durable even when exposed to harsh chemicals or extreme conditions. 2. Durability and Strength: Steel wire mesh is renowned for its strength and durability. It can withstand heavy loads, high temperatures, and mechanical stress without deformation or damage. This makes it ideal for supporting heavy equipment or withstanding pressure from chemical reactions. 3. Versatility: Steel wire mesh comes in a wide range of sizes, shapes, and configurations, making it highly versatile for different applications in the chemical refurbishing industry. It can be used as a filtration medium, support structure, reinforcement material, or even as a safety barrier. 4. Easy Maintenance: Steel wire mesh requires relatively low maintenance compared to other materials. It is resistant to rust and corrosion, reducing the need for frequent replacements and repairs. Additionally, its smooth surface facilitates easy cleaning, ensuring it remains free from contaminants and debris. 5. Cost-Effectiveness: Despite its durability and strength, steel wire mesh is cost-effective compared to other materials. It has a long lifespan, reducing the need for frequent replacements, and its low maintenance requirements contribute to long-term cost savings. 6. Enhanced Safety: Steel wire mesh enhances safety in the chemical refurbishing industry. It can be used as a protective barrier to prevent accidents or injuries by containing hazardous substances or restricting access to potentially dangerous areas. In summary, utilizing steel wire mesh in the chemical refurbishing industry offers benefits such as chemical resistance, durability, versatility, easy maintenance, cost-effectiveness, and enhanced safety.

- Yes, steel wire mesh is suitable for use in hydroponic systems. It provides excellent support for plants, allowing their roots to receive adequate air and nutrients. Additionally, steel wire mesh is durable and long-lasting, making it a reliable choice for hydroponic setups.

- Steel wire mesh brings numerous advantages to the manufacturing industry. To begin with, its exceptional strength and durability enable it to bear heavy loads and withstand high temperatures, making it an ideal option for applications that demand a robust material. Its resilience against wear and tear further ensures a longer lifespan compared to alternative materials. Furthermore, steel wire mesh offers remarkable versatility. It can be effortlessly shaped and molded into diverse forms and sizes, making it suitable for a wide array of manufacturing applications. Whether it is employed for filtration, separation, reinforcement, or containment purposes, steel wire mesh can be tailored to meet specific requirements. In addition, steel wire mesh provides excellent visibility and airflow. Its open design permits the passage of light, air, and sound, making it highly desirable for applications that necessitate optimal visibility or ventilation. This attribute proves particularly advantageous in industries such as construction, agriculture, and automotive manufacturing. Moreover, steel wire mesh proves to be cost-effective. Its durability and longevity dramatically reduce the need for frequent replacements, resulting in substantial savings in maintenance and replacement expenses. Additionally, its widespread availability and easy sourcing further contribute to its cost-effectiveness. Furthermore, steel wire mesh exhibits resistance to corrosion. This attribute renders it suitable for applications in harsh environments or industries that handle chemicals or moisture. The corrosion resistance ensures that the mesh retains its structural integrity and functionality over time. Lastly, steel wire mesh promotes environmental friendliness. It is manufactured using recyclable materials, and its prolonged lifespan curbs waste generation. Furthermore, it can be recycled at the end of its useful life, further minimizing its environmental impact. In conclusion, steel wire mesh boasts numerous benefits for the manufacturing industry, including its strength, versatility, visibility and airflow properties, cost-effectiveness, corrosion resistance, and environmental friendliness. These advantages establish steel wire mesh as an outstanding choice for various applications within the manufacturing sector.

- Due to its high metal content, steel wire mesh possesses excellent electrical conductivity. Typically comprising iron and carbon, with trace amounts of other elements, the steel utilized in wire mesh allows for the unhindered movement of electrons, resulting in its role as a proficient conductor of electricity. The electrical conductivity of steel wire mesh can fluctuate based on several factors, including wire gauge, wire spacing, and overall mesh thickness. Generally, thicker wires which are more closely spaced contribute to enhanced conductivity. In applications necessitating electrical conductivity, steel wire mesh is frequently employed. Examples include electrical enclosures, grounding systems, and electromagnetic shielding. The mesh's conductivity properties facilitate the smooth flow of electric current, thereby minimizing the likelihood of electrical hazards and ensuring dependable electrical connections. Nonetheless, it is important to acknowledge that steel wire mesh may not be suitable for all electrical applications. In scenarios involving high frequencies or low resistance, materials such as copper or aluminum may offer superior conductivity. Furthermore, the presence of rust or corrosion on the wire mesh can detrimentally impact its electrical conductivity. Regular upkeep and proper maintenance are required to uphold optimal conductivity properties of steel wire mesh.

- Yes, steel wire mesh can be used for scaffolding. It is a commonly used material for providing support and stability in construction and building projects. The strength and durability of steel wire mesh make it suitable for scaffolding, as it can safely hold the weight of workers and equipment. Additionally, the mesh design allows for better visibility and airflow, enhancing safety and comfort on the scaffold.

- Mesh baskets can indeed utilize steel wire mesh. This material is frequently employed for various purposes, mesh baskets being one of them. With its strength, durability, and corrosion resistance, steel wire mesh proves to be the perfect choice for constructing baskets capable of enduring heavy loads and harsh environments. Moreover, the mesh's open structure facilitates adequate airflow and visibility, rendering it suitable for storing and arranging items. Furthermore, steel wire mesh can be effortlessly tailored to different dimensions and forms, granting flexibility in designing mesh baskets to suit specific requirements.

- Steel wire mesh is indeed resistant to pests. Due to its tightly woven structure, pests like insects or rodents find it challenging to penetrate through. Consequently, it serves as a highly effective obstacle against unwelcome intruders in diverse scenarios. It proves valuable in safeguarding gardens from pests, ensuring the protection of vents and windows from insects, and preventing the entry of small animals into properties. Moreover, steel wire mesh exhibits remarkable durability and can endure various environmental conditions, thus providing a lasting solution for pest control.