Galvanized Hexagonal Wire Netting Before Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

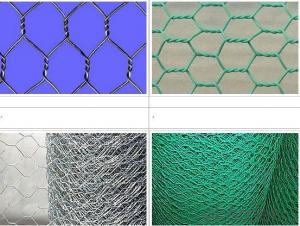

Pictures of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:What are the different roll sizes available for steel wire mesh?

- The steel wire mesh available in rolls can vary in size based on the specific needs and requirements of the application. Typically, there is a range of roll sizes for steel wire mesh to accommodate different project sizes and installations. Examples of common roll sizes for steel wire mesh are 4 feet by 50 feet, 5 feet by 100 feet, 6 feet by 150 feet, and 8 feet by 200 feet. However, it's important to note that these are just a few examples and other roll sizes may be offered by the manufacturer or supplier. To determine the most suitable roll sizes for your project, it is recommended to consult with the specific manufacturer or supplier.

- Q:How is steel wire mesh used in reinforcement of chemical and petrochemical facilities?

- Steel wire mesh is commonly used in the reinforcement of chemical and petrochemical facilities due to its exceptional strength and durability. These facilities often deal with harsh and corrosive environments, which require materials that can withstand extreme conditions. In chemical and petrochemical facilities, steel wire mesh is primarily used for reinforcement in concrete structures. Concrete is a widely used construction material due to its high compressive strength, but it lacks tensile strength. By incorporating steel wire mesh into concrete structures, it helps to enhance the overall strength and structural integrity. Steel wire mesh is typically embedded within the concrete to form a reinforcing grid. This grid acts as a reinforcement system, distributing the load evenly across the structure and preventing cracks or failures. The mesh reinforces the concrete by resisting tensile forces and providing stability, especially in areas prone to high stress or potential impact. Moreover, steel wire mesh is highly resistant to corrosion, making it an ideal choice for chemical and petrochemical facilities. The exposure to various chemicals, high temperatures, and moisture in these facilities can cause significant damage to the reinforcement materials. However, steel wire mesh has excellent corrosion resistance properties, ensuring long-term durability and structural stability. Additionally, steel wire mesh can be customized to meet specific requirements, such as different mesh sizes and wire diameters. This versatility allows engineers and contractors to design and reinforce structures based on the specific needs of the chemical and petrochemical facilities. Overall, the use of steel wire mesh in the reinforcement of chemical and petrochemical facilities provides numerous benefits, including increased strength, durability, and corrosion resistance. It plays a crucial role in ensuring the safety and longevity of these facilities in challenging environments.

- Q:How does steel wire mesh perform in terms of resistance to chemical exposure?

- Steel wire mesh performs well in terms of resistance to chemical exposure. It is highly resistant to corrosion and degradation when exposed to various chemicals, making it a reliable choice for applications where chemical resistance is required.

- Q:What are the different opening sizes available for steel wire mesh?

- The opening sizes available for steel wire mesh can vary depending on the specific requirements and applications. However, common opening sizes for steel wire mesh typically range from small openings such as 1/4 inch to larger openings like 2 inches or more.

- Q:How does the surface pattern affect the grip of steel wire mesh?

- The surface pattern of steel wire mesh directly affects its grip by providing additional friction and traction. A pattern with raised or textured surfaces enhances the grip by increasing the contact area between the mesh and the object being held or supported. This improved grip is particularly important in applications where stability, strength, and secure fastening are required, such as in construction, fencing, or industrial settings. The selection of an appropriate surface pattern can significantly enhance the overall grip and performance of steel wire mesh.

- Q:How does steel wire mesh perform in terms of resistance to wear?

- Steel wire mesh exhibits remarkable wear resistance, owing to its exceptional performance. Its steel wire, renowned for its high tensile strength, grants it exceptional durability against various forms of wear and tear. The mesh structure effectively prevents fraying or breakage under pressure, guaranteeing a prolonged lifespan, even in high-stress scenarios. Moreover, steel wire mesh boasts superior resistance to corrosion, rust, and other chemical deteriorations, thereby augmenting its resistance to wear. Whether employed in construction, industrial environments, or as fencing, steel wire mesh is renowned for its capacity to withstand heavy usage while retaining its structural integrity throughout time.

- Q:Can steel wire mesh be used for creating mesh screens?

- Yes, steel wire mesh can be effectively used for creating mesh screens. Steel wire mesh is known for its high strength, durability, and resistance to corrosion, making it an ideal material for constructing mesh screens. The tightly woven pattern of the wire mesh allows for the passage of air and light while effectively preventing the entry of insects, debris, or other unwanted particles. Additionally, steel wire mesh can be easily cut, shaped, and customized to fit various screen sizes and shapes, making it highly versatile for different applications. Whether for windows, doors, fencing, or industrial applications, steel wire mesh is a reliable choice for creating mesh screens due to its sturdiness and long-lasting performance.

- Q:Can steel wire mesh be used for gabion benches?

- Indeed, gabion benches can utilize steel wire mesh. These benches are essentially seating structures that consist of gabion baskets, which are containers made of wire mesh and filled with stones or rocks. The steel wire mesh employed in gabion benches offers both structural support and stability to the seating area, guaranteeing the benches' longevity and ability to withstand the weight of individuals sitting on them. Moreover, the wire mesh facilitates proper drainage, averting the accumulation of water and potential harm to the bench. In summary, due to its strength, durability, and functionality, steel wire mesh proves to be a suitable material for constructing gabion benches.

- Q:Is steel wire mesh suitable for use in oil and gas industry applications?

- Yes, steel wire mesh is suitable for use in oil and gas industry applications. Steel wire mesh offers several properties that make it ideal for use in this industry. Firstly, steel wire mesh is highly durable and can withstand harsh conditions, including extreme temperatures and corrosive environments. This is crucial in the oil and gas industry where equipment and infrastructure are exposed to corrosive substances and high-pressure environments. Additionally, steel wire mesh has excellent strength and can provide structural support and reinforcement in various applications such as fencing, filtration, and insulation. It can withstand heavy loads and is resistant to deformation, making it suitable for use in oil and gas pipelines, storage tanks, and processing equipment. Moreover, steel wire mesh can be manufactured to meet specific requirements, including mesh size, wire diameter, and material grade. This allows for customization to suit different applications, such as filtration for oil and gas separation or protection against debris and wildlife. Lastly, steel wire mesh is cost-effective and offers a long lifespan, reducing maintenance and replacement costs. Its availability and ease of installation also make it a practical choice for oil and gas industry applications. Overall, steel wire mesh is a reliable and versatile material that can meet the demanding needs of the oil and gas industry. Its strength, durability, customizability, and cost-effectiveness make it a suitable choice for various applications within this sector.

- Q:How does the color affect the visibility of steel wire mesh?

- The color of steel wire mesh can have an impact on its visibility, although it is not the primary factor. The visibility of steel wire mesh primarily depends on its size, pattern, and the environment in which it is placed. However, color can play a secondary role in determining how visible the mesh is. In general, lighter-colored steel wire mesh, such as silver or white, tends to be more visible in darker environments. This is because lighter colors reflect more light, making the mesh stand out against its surroundings. On the other hand, darker-colored steel wire mesh, such as black or dark gray, may blend in more easily in low light conditions or when placed against dark backgrounds. However, it is important to note that color alone does not determine the visibility of steel wire mesh. Mesh size and pattern, as well as the lighting conditions and background against which it is placed, have a more significant impact on its visibility. For example, a larger mesh size with a distinct pattern will be more visible regardless of its color. Furthermore, in certain specific applications, such as security fencing or architectural purposes, the color of steel wire mesh may be chosen to blend in with the surrounding environment or match the overall aesthetic. In these cases, visibility may not be the primary concern, and other factors, such as durability or design, may take precedence. In summary, while the color of steel wire mesh can influence its visibility to some extent, it is not the sole determining factor. Mesh size, pattern, lighting conditions, and background play a more significant role in determining the visibility of steel wire mesh.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Hexagonal Wire Netting Before Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords