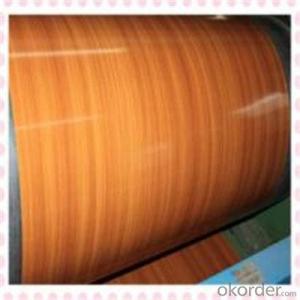

Wood Pattern Printing Galvanized PPGI Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description of PPGI:

1. Zinc coating :40-180g( as required)

2. thickness:0.2-1.2mm

3. width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

4. coil id:508mm/610mm

5. coil weight: 4-10 MT(as required)

6. surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

Festures of PPGI:

Building industry | Outdoor application | Roof, structural balcony, panels, window sills, window frames, gates, garage doors |

Indoor application | Room doors, dividing walls, door frames, light house steel structures, sliding doors |

Specifications of PPGI:

Specifications | |

Name | buy wood grain design ppgi!bs approved printed ppgi!prime quality cr steel coil |

Full name | Galvanized ,Galvalume,Pre-paited galvanizing,Pre-paited galvalume |

Basic material | Cold Roll |

Color of the PPGI and PPGL | Any color in RAL |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Spangle | Normal / Min / Zero |

Thickness | 0.14mm-2.0mm |

Width | 750mm to 1250mm |

Images of PPGI:

FAQ:

1.What about the delivery.

We can arrange the shipment about 15-25 days after the deposit.

2.What about payment term?

30% T/T deposit, balance against B/L copy.

Full T/T payment if quantity less than MOQ.

3.How much about MOQ?

Normally 100pcs,but small order is acceptable as well.

- Q:What are the common methods of painting or coating steel coils?

- One common method of painting or coating steel coils is through the process of coil coating. In coil coating, the steel coils are first cleaned and pre-treated to remove any contaminants and improve adhesion. Then, a primer or a base coat is applied to the coils to provide a foundation for the final coating. This primer helps in protecting the steel from corrosion and improves the overall durability of the coating. After the primer is applied, the steel coils pass through a series of rollers where the topcoat is applied. The topcoat can be a variety of materials such as polyester, polyurethane, or fluoropolymer, depending on the desired properties of the final coating. These topcoats provide the desired color, gloss, and protection against weathering, chemical exposure, and UV radiation. Another common method of painting or coating steel coils is through the process of electrostatic spraying. In this method, a paint or coating material is atomized into fine droplets and then charged with an electrical charge. The steel coils, which are grounded, attract the charged droplets, resulting in an even and controlled application of the paint or coating material. Powder coating is yet another method used for painting or coating steel coils. In this process, a dry powder is electrostatically charged and sprayed onto the steel coils. The charged powder adheres to the surface of the steel due to electrostatic attraction. The coated steel coils are then heated, causing the powder to melt and form a continuous film, providing a durable and resistant coating. Overall, these methods of painting or coating steel coils offer a wide range of options in terms of color, finish, and performance characteristics. The choice of method depends on factors such as the desired appearance, level of protection needed, and the specific requirements of the intended application.

- Q:I live in the Black Hills and I need to re-side my cottage. I like the look of vinyl. I've heard pros and cons about both steel and vinyl. Is steel really that easy to dent? It just doesn't look as 'clean' as vinyl. Also what 3 color combos do you like? My cottage has shutters.

- I'd like to know why you need to re-side it. I would get vinyl because it will not need painting as soon as steel.

- Q:How are steel coils inspected for flatness?

- To ensure they meet the necessary standards, steel coils undergo a variety of methods and techniques to inspect their flatness. Trained inspectors visually examine the coil's surface for signs of waviness or unevenness, searching for visible defects like waves, buckles, or twists that could impact its flatness. Another approach involves using specialized equipment such as flatness gauges or profilometers to inspect the coil's flatness. These instruments measure the surface profile and provide detailed information about any deviations from the desired flatness. They can detect both local and overall flatness issues, offering a more precise assessment of the coil's quality. In addition to visual and instrumental inspections, physical tests can also be conducted to evaluate the flatness of steel coils. The "drape" test, for instance, involves draping the coil over a flat surface and measuring any noticeable gaps or unevenness. This test quickly identifies major flatness problems. Moreover, computerized analysis and simulation techniques are gaining popularity for inspecting the flatness of steel coils. These methods utilize advanced software to analyze the coil's surface data and generate comprehensive reports on its flatness characteristics. By comparing the actual surface profile with the desired specifications, these techniques provide a thorough assessment of the coil's flatness. Overall, the inspection of steel coils for flatness combines visual inspection, specialized equipment, physical tests, and advanced analysis techniques. These methods ensure that the coils meet the necessary flatness standards, which is essential for their successful application in industries such as automotive, construction, and manufacturing.

- Q:How are steel coils coated to prevent corrosion?

- Steel coils are coated to prevent corrosion through a process known as galvanization. This involves applying a protective layer of zinc onto the surface of the steel coils. The zinc acts as a barrier, preventing the steel from coming into contact with moisture and oxygen, which are the main causes of corrosion. This coating not only provides excellent corrosion resistance but also enhances the durability and longevity of the steel coils.

- Q:How are steel coils used in the production of electrical connectors?

- Steel coils are used in the production of electrical connectors as they are often used as a raw material for manufacturing the connector pins. The steel coils are typically shaped and cut to specific dimensions to create the pins, which are then inserted into the connectors to establish electrical connections.

- Q:How do steel coils affect the quality of finished products?

- Steel coils can have a significant impact on the quality of finished products. Their quality, including dimensions, surface condition, and mechanical properties, directly affects the final product's strength, durability, and appearance. Coils with inconsistent dimensions or surface defects can lead to uneven or weak finished products. Similarly, if the mechanical properties of the coils do not meet the required specifications, it can compromise the performance and functionality of the end product. Therefore, ensuring the high quality of steel coils is crucial for achieving superior finished product quality.

- Q:so i've started learning to play guitar in the past few weeks, and i'm using my sister's old guitar which isn't in very good condition, so i'm planning on buying a new one, but which would be better to buy, nylon string or steel string?

- it all depends nylon is faster, and brighter than steel, but is available only on acoustic as coil pickups won't detect them(only peizo will). That is one reason. Another is price, you tend to replace the nylon more often as it is weaker, and less resistant to corrision. EVEN THOUGH strings have a larger price range, and be cheaper than steel, or considerably more expensive. overall the nylon is brighter, but quite-er. Steel is louder, but deeper. nylon doesn't get feedback as easily, and is amazingly fast and easy to play. some think nylon sounds old fashoined(it looks it too, with an open headstock, ond classical look(sometimes mistaken as another name for it). MY SUGGESTION- visit your local music shop and try out steel, and nylons to in person get a feel for the sound.(remember that you get what you pay for, go as high in price as you can reasonably afford) ALWAYS TRY BEFORE YOU BUY, PLAY BOTH TYPES IN THE SAME RANGE OF PRICE(at least $400), THEN DECIDE WHAT SOUNDS BETTER TO YOU(and of course feels better and easier to play).

- Q:What are the weight ranges of steel coils?

- The weight ranges of steel coils can vary widely depending on the specific type and dimensions of the coil. However, typical weight ranges for steel coils can range from a few hundred kilograms to several tons.

- Q:does regular steel rust? or is it all the same.

- Dear, Thank you, am also fine like you then dear yeah is the same.

- Q:I have taylormade burner steel irons and I was wondering what would the flex of steel be if you were to compare it to graphite shafts, like regular, stiff, super stiff, etc...THANKS!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- If i understand you correctly, i think you misunderstand shafts. Steel shafts vs. graphite shafts these days is more of a competition of weights, not flexibility. Both steel and Graphite have different flex profiles available from Ladies (L) to super stiff (X). Graphite may feel a little more whippy than steel because of the lighter weight. Shafts will vary by company as well. Stiff from True temper may not be as stiff as one from Aldila, or vice verse. You can also make a shaft play stiffer or more flexible by where you cut the length. This is called tipping. Take more from the bottom and it will be stiffer, more from the grip end and it will play more flexible.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood Pattern Printing Galvanized PPGI Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords