Wood Grain Printing Galvanized PPGI Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description of PPGI:

1. Zinc coating :40-180g( as required)

2. thickness:0.2-1.2mm

3. width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

4. coil id:508mm/610mm

5. coil weight: 4-10 MT(as required)

6. surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

Festures of PPGI:

Building industry | Outdoor application | Roof, structural balcony, panels, window sills, window frames, gates, garage doors |

Indoor application | Room doors, dividing walls, door frames, light house steel structures, sliding doors |

Specifications of PPGI:

1) Steel buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, doors,window frames etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks etc.

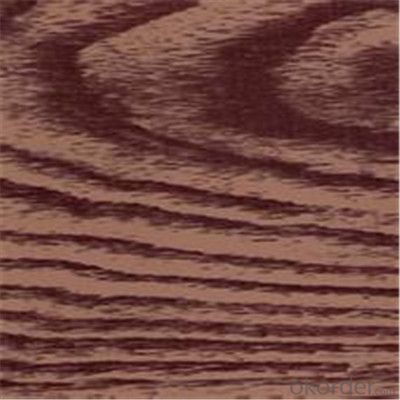

Images of PPGI:

FAQ:

1.What about the delivery.

We can arrange the shipment about 15-25 days after the deposit.

2.What about payment term?

30% T/T deposit, balance against B/L copy.

Full T/T payment if quantity less than MOQ.

3.How much about MOQ?

Normally 100pcs,but small order is acceptable as well.

- Q:What are the different types of coatings applied to steel coils?

- There are various types of coatings that can be applied to steel coils, each with its own specific purpose and benefits. 1. Galvanized Coating: This is one of the most common types of coatings applied to steel coils. It involves the application of a layer of zinc to the steel surface. Galvanized coatings provide excellent corrosion resistance, making them suitable for outdoor applications where the steel may be exposed to moisture or harsh environmental conditions. 2. Galvalume Coating: Similar to galvanized coating, galvalume coating also involves the application of a layer of zinc to the steel surface. However, it also includes a small amount of aluminum, which enhances the corrosion resistance and provides better heat reflectivity. Galvalume coatings are often used in roofing and cladding applications. 3. Pre-painted Coating: Pre-painted coatings involve the application of a layer of paint or primer to the steel surface. This type of coating allows for customization in terms of color and finish. Pre-painted coatings not only enhance the aesthetics of the steel but also provide additional protection against corrosion and weathering. 4. Organic Coating: Organic coatings are typically applied as a topcoat over a galvanized or galvalume coating. They are made of various resins, such as polyester, epoxy, or polyurethane, which provide additional protection against corrosion, abrasion, and chemicals. Organic coatings are commonly used in applications where both aesthetics and durability are important, such as in the automotive industry. 5. Metallic Coating: Metallic coatings, such as aluminum or zinc, are applied to steel coils using a process called hot-dip coating. These coatings provide excellent corrosion resistance and are commonly used in applications where the steel is exposed to high temperatures or corrosive environments. 6. Chromate Conversion Coating: Chromate conversion coatings are applied to steel coils primarily for their corrosion resistance properties. They are commonly used in electrical applications to protect against galvanic corrosion and improve conductivity. Overall, the type of coating applied to steel coils depends on the specific requirements of the application, including the desired level of corrosion resistance, aesthetics, and environmental factors.

- Q:Hello. right now i have been playing electric and acoustic guitar for 6 years. I currently became very interested in learning the pedal steel guitar. I will be teaching myself so is it really hard to learn? Are there a lot of songs online that could give me tabs? Basically im asking if it is worthwhile to spend a lot of money. I dont want it if there are only 3 songs im gona learn. im up for the challenge im just curious how hard it was to learn. thanks for your help.

- The okorder /... Beware of eBay deals unless you know what you're buying. To start, you should get a 10-string single neck with 3 pedals and 4 levers. Some of the student models don't have as many levers and aren't capable of all the changes you need. Stay away from the ShoBud Maverick...you'll outgrow it in a couple of months. Often it makes more sense to buy a used professional model...you'll eventually need one, and they hold their value better than a student model. You'll also need a volume pedal, bar, thumb and finger picks. For now, your guitar amp will be ok. Playing the guitar: There are several tunings and lots of different combinations of levers, but the basic guitar is a 10 string E9 tuning. It's almost an open E but with a few extra notes. The pedals and levers raise and lower the pitch of selected strings. Chord changes are made by moving the bar and pressing pedals and levers. The volume pedal helps you swell and sustain notes. Steel has it's own unique tablature which reflects all these changes. If you have any other questions, feel free to email me or just join the PSG forum and ask there.

- Q:What are the different types of steel coil surface defects?

- During the manufacturing or handling process, various steel coil surface defects may arise. Some commonly encountered types are as follows: 1. Rust: When moisture or oxygen comes in contact with the steel coil, rust, a reddish-brown discoloration, may develop on its surface. 2. Scratches: While the steel coil is being handled or transported, superficial marks known as scratches can be incurred. These marks can vary in depth and severity, ranging from light surface scratches to deep gouges. 3. Stains: Exposure to chemicals or other substances can lead to stains, discolored patches that appear on the coil's surface. Removing them may prove to be challenging. 4. Roll marks: During the rolling process, impressions or indentations called roll marks may form. Uneven pressure or misalignment of the rolls causes them, resulting in lines or patterns on the coil's surface. 5. Edge wave: Imperfectly flat edges of the coil can result in a defect known as edge wave. This defect causes the edges to appear wavy or uneven and can impact the coil's overall appearance and performance. 6. Oil spots: If the oil or lubricants utilized in the manufacturing process are not adequately removed, surface defects called oil spots can manifest. These spots appear as dark patches or spots on the coil's surface and may hinder the adhesion of coatings or paints. 7. Pitting: Small, shallow depressions or pits on the coil's surface are indicative of a defect called pitting. Factors like corrosion, uneven cooling, or impurities in the steel can cause this defect. 8. Holes: Holes are severe surface defects that can arise due to various factors, including corrosion, mechanical damage, or manufacturing errors. These defects come in different sizes and can significantly compromise the coil's structural integrity. Promptly addressing these surface defects is crucial for maintaining the quality and performance of the steel coil. Regular inspections, proper handling, and appropriate surface treatments can help minimize the occurrence of these defects.

- Q:How are steel coils used in the production of building systems?

- Steel coils are used in the production of building systems as they provide a cost-effective and versatile material for various construction applications. These coils are often processed and shaped into different components, such as beams, columns, and roofing materials, to meet the structural requirements of buildings. The strength and durability of steel make it an ideal choice for constructing high-rise buildings, industrial facilities, and other structures that require stability and longevity.

- Q:So I was thinking about doing corset waist training and I wanted to know where I can get a real steel boned corset?

- Hi, okorder / There are 3 types of corsets: Fashion corsets, Authentic corsets and Waist training corsets. The fashion corsets are designed for light enclasping of body. They are made with plastics bones usually. The authentic corsets can reduce your waist size about 4 - 5 and the waist training corsets about 6. They both are made with steel spirals and flat bones. The waist training corsets are recommended for experienced wearers only. Look on info pages of the seller. The corsets reinforced with plastic bones are cheap with low durability.

- Q:What are the different methods of slitting edge trimming for steel coils?

- Steel coils can be slit using various methods, each with its own benefits and applications. 1. Rotary Shear Slitting: This approach utilizes rotary knives mounted on a rotating shaft to cut through the steel coil. The knives create a shearing action as they pass through the coil. Rotary shear slitting is versatile, accommodating various coil thicknesses and materials. It is commonly employed for high-volume production, offering clean and precise cuts. 2. Crush Cut Slitting: This method involves pressing the steel coil against a hardened anvil with a rotating knife. The coil is cut by crushing it against the anvil. Crush cut slitting is suitable for thinner gauge materials and those sensitive to shearing forces. It provides clean cuts but may have limitations in terms of coil thickness and width. 3. Razor Slitting: Razor slitting employs a razor blade mounted on a rotating shaft to slice through the steel coil. This method is commonly used for thin and delicate materials that require precise and burr-free edges. While it provides clean cuts, it may be limited in terms of coil thickness and width. 4. Shear Slitting: This approach utilizes a pair of opposing blades to shear through the steel coil. The blades move past each other, creating a scissor-like cutting action. Shear slitting is commonly used for heavier gauge materials, offering clean and precise cuts. It is suitable for high-speed production and can handle a wide range of coil thicknesses and materials. 5. Laser Slitting: Laser slitting employs a high-powered laser beam guided by computer-controlled optics to cut through the steel coil. It offers precise and clean cuts and is suitable for various coil thicknesses and materials, including high-strength steels. Laser slitting provides a high level of accuracy and can handle complex cutting patterns. Each method has its own advantages and considerations, depending on the specific requirements of the steel coil slitting operation. Factors such as coil thickness, material type, desired edge quality, and production volume will influence the choice of slitting method.

- Q:How are steel coils processed for slitting or edge trimming?

- Steel coils are processed for slitting or edge trimming by feeding them into a machine called a slitter. The slitter cuts the coils into narrower strips, which are then rewound onto separate spools. Edge trimming is done to remove any irregularities or imperfections from the edges of the strips, ensuring a smooth and uniform finish.

- Q:I went to the store to get metal to make a knife and they had weldable steel and plate steel. Which one would be best/ which steels would be best for what i want to do?

- 'Plate' does not refer to a specific alloy. It simply describes the shape in which the metal is sold. Various steel alloys have varying degrees of weldability. Some weld well, with good strength. Others weld poorly, and crack or become very weak. Try looking up information on the specific alloy of steel.

- Q:I saw this really pretty ring online and it was made of steel. Is this a good ring? If I were to wash my hands with it on, would it rust and turn my finger green?

- Steel rust is brown not green! Very much expected to be of one type of stainless steel, and you should have no problem.

- Q:What are the common coil thickness and width combinations available for steel coils?

- The common coil thickness and width combinations available for steel coils can vary depending on the specific requirements and standards of the industry. However, there are some commonly found combinations that are widely used. In terms of coil thickness, common options range from thin to thick coils. Thin coils typically have a thickness ranging from 0.4mm to 3.0mm, while medium thickness coils can be around 3.0mm to 6.0mm. For thicker coils, the range can be from 6.0mm to 25.0mm or even higher, depending on the specific application. Regarding coil width, it also varies based on the intended usage. Some common options include coils with widths of 600mm, 750mm, 900mm, 1000mm, 1200mm, 1250mm, and 1500mm. However, wider or narrower coils can also be available depending on the specific requirements of the customer or industry. Ultimately, the most suitable coil thickness and width combination will depend on factors such as the intended application, manufacturing processes, transportation limitations, and customer preferences. It is essential to consult with steel coil manufacturers or suppliers to determine the most appropriate options for your specific needs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood Grain Printing Galvanized PPGI Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords