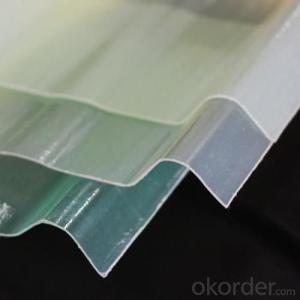

Translucent Fiberglass Roofing Sheets, Corrugated Fiberglass Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATIONS

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q:Can FRP roofing panels be used for warehouses?

- Yes, FRP roofing panels can be used for warehouses. FRP (Fiberglass Reinforced Plastic) roofing panels are known for their durability, lightweight nature, and resistance to corrosion and chemicals. These qualities make them suitable for various applications, including warehouses. They offer excellent protection against weather elements, provide natural light transmission, and are easy to install and maintain.

- Q:Do FRP roofing panels provide sound insulation?

- No, FRP (Fiberglass Reinforced Plastic) roofing panels do not provide significant sound insulation. While they may slightly reduce noise compared to a bare roof surface, they are not designed or intended to be soundproof. FRP panels are primarily used for their durability, weather resistance, and light transmission properties, rather than for their sound insulation capabilities. For sound insulation, other roofing materials or additional soundproofing measures would be more suitable.

- Q:Are FRP roofing panels suitable for gymnasiums or sports facilities?

- FRP roofing panels prove to be a suitable option for gymnasiums and sports facilities. These panels, which are made of fiberglass reinforced plastic, are renowned for their strength and durability. They possess resistance against various weather factors like UV rays, moisture, and chemicals, making them perfect for both outdoor sports facilities and indoor gyms with high humidity levels. What sets FRP panels apart is their lightweight nature, making installation a breeze and saving time. Moreover, they offer exceptional thermal insulation, thereby reducing energy costs associated with heating or cooling the facility. Additionally, FRP panels can be translucent, allowing natural light to permeate the space. This aspect proves to be highly advantageous for indoor sports facilities that require optimal lighting conditions. When it comes to maintenance, FRP panels require relatively minimal upkeep compared to traditional roofing materials. They possess resistance against mold, mildew, and corrosion, ensuring a longer lifespan for the roofing system. Furthermore, cleaning FRP panels is a simple task that does not demand significant effort. To summarize, FRP roofing panels present numerous benefits, making them a fitting choice for gymnasiums and sports facilities. Their durability, resistance to weather elements, thermal insulation properties, and low maintenance requirements contribute to their cost-effectiveness and reliability for such structures.

- Q:Can FRP roofing panels be used for both pitched and flat roofs?

- Both pitched and flat roofs can make use of FRP (Fiberglass Reinforced Plastic) roofing panels. These panels are adaptable and can suit different roof types and designs. They possess excellent durability, weather resistance, and insulation properties, making them appropriate for residential and commercial purposes. For pitched roofs, FRP roofing panels are typically installed as a covering material over the roof structure. They can be secured using screws or adhesive, providing protection against harsh weather conditions. The pitched design facilitates efficient water drainage, preventing water accumulation and potential leakage. In contrast, FRP roofing panels can also be employed for flat roofs. In this scenario, they are frequently utilized as a waterproofing layer or as part of a multi-layer roofing system. The panels are laid flat and joined together using sealants or overlapping techniques to create a watertight seal. Additionally, FRP panels can be reinforced with extra layers or coatings to enhance their resistance to UV radiation, impact, and other external factors. It is crucial to note that proper installation and compliance with building codes and regulations are essential when using FRP roofing panels. It is advisable to consult with a professional roofing contractor or manufacturer to ensure the panels are correctly installed and suitable for the specific roof type and conditions. In conclusion, FRP roofing panels offer a cost-effective and long-lasting solution for both pitched and flat roofs, making them a popular choice in the construction industry. Their versatility, strength, and ability to withstand harsh weather conditions make them a reliable option for various roof designs and applications.

- Q:Can FRP roofing panels be installed on mobile homes?

- FRP roofing panels are indeed compatible with mobile homes. Their lightweight, durable, and weather-resistant properties render them an ideal choice for such structures. Their ease of installation and maintenance further contribute to their popularity among mobile home owners. Nonetheless, it is crucial to verify the mobile home's structural capacity to bear the weight of these panels and to ensure a leak-free and damage-free installation. Seeking professional advice to evaluate the appropriateness and practicality of using FRP roofing panels on a particular mobile home is also highly recommended.

- Q:Can FRP roofing panels be cut to size on-site?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be cut to size on-site. FRP panels are relatively easy to cut using common tools such as circular saws, jigsaws, or even basic hand tools like utility knives. However, it is important to follow the manufacturer's guidelines and recommendations when cutting FRP panels to ensure a clean and accurate cut. Additionally, proper safety measures should be taken, such as wearing protective eyewear and gloves, as cutting FRP panels can generate dust and small particles. Overall, cutting FRP roofing panels on-site allows for customization and flexibility in fitting the panels to the specific dimensions of a project.

- Q:Are FRP roofing panels compatible with different types of flashing systems?

- Yes, FRP roofing panels are compatible with a variety of flashing systems. These panels can be easily integrated with different types of flashing systems, such as metal or PVC, to ensure proper waterproofing and protection against leaks. Proper installation and sealing techniques are crucial to ensure a secure and durable connection between the FRP panels and the flashing system.

- Q:Are FRP roofing panels resistant to solvents?

- Generally, solvents do not affect FRP (Fiberglass Reinforced Plastic) roofing panels due to their composition, which combines fiberglass and a plastic resin matrix. The fiberglass provides strength and stability, while the plastic resin offers resistance to various chemicals, including solvents. However, it is important to consider that the resistance of FRP roofing panels to solvents may vary depending on the type and concentration of the solvent used. While most common solvents will not harm FRP panels, aggressive solvents or prolonged exposure to certain chemicals can lead to material degradation or discoloration. To ensure compatibility between the FRP roofing panels and the solvents you plan to use, it is advisable to consult the manufacturer or supplier. They can provide specific information and guidance regarding the panels' resistance to the solvents and chemicals relevant to your application.

- Q:Can FRP roofing panels be used for outdoor kitchens?

- Outdoor kitchens can indeed utilize FRP (Fiberglass Reinforced Panels) roofing panels. These panels are quite popular for outdoor applications due to their durability, ability to withstand harsh weather conditions, and low maintenance requirements. They are specifically designed to endure rain, snow, sunlight, and other harsh elements, making them an ideal choice for outdoor kitchens. FRP roofing panels are lightweight yet incredibly sturdy, which makes them easy to install and handle. They are also resistant to corrosion, rust, and rot, which is crucial for outdoor environments that experience moisture and humidity. Additionally, these panels come in various colors and styles, allowing you to select a design that complements your outdoor kitchen's aesthetic. Furthermore, FRP panels offer excellent insulation properties, which help regulate temperature and reduce energy costs in outdoor kitchens. They effectively prevent heat transfer, ensuring the space remains cooler during hot summer days and warmer during colder seasons. Overall, FRP roofing panels are a reliable and practical option for outdoor kitchens. They provide durability, weather resistance, low maintenance, and insulation properties, making them a worthwhile investment for creating a functional and visually appealing outdoor cooking area.

- Q:Can FRP roofing panels be installed without professional assistance?

- It is possible to install FRP roofing panels without professional assistance, but it is recommended to have some knowledge and experience in roofing installations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Translucent Fiberglass Roofing Sheets, Corrugated Fiberglass Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords