Fiber Reinforce Plastic Sheet Panel with 2.0 mm Thinkness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber Reinforce Plastic Sheet Panel with 2.0 mm Thinkness

Description

FRP sheets are made of fiberglass and polyester resin and continuously molded by machine.

They are characterized by high-light transmittance, light-weight, high-strength, corrosion resistance, impact resistance, anti-ultraviolet, anti-

static, heat preservation and insulation, accurate section dimensions and controllable cutting length. They can be used with various profiling panels and galvanized sheets.

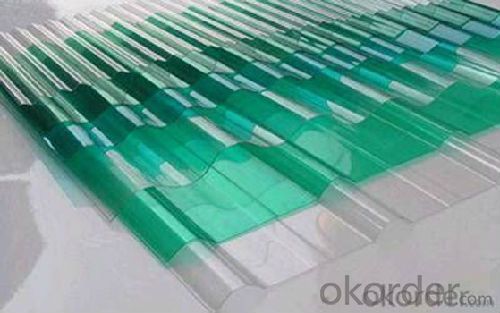

Photos

Product Traits

Good tenacity. No cracking phenomenon when driving nails in roof installation.

Having close combing with color steel plate. Cross-section thickness is uniform. The shape of FRP is consistent with steel plate.

Transmittance loss rate is low. No yellowing phenomenon after long term service.

Thermal expansion coefficient is close to that of steel plate. No cracking and water leakage in nail driving place because of expand with heat and contract with cold.

Light through FRP assumes scattering shape and gentle.

Bright and clean appearance. No distinct air bubble and cracking on FRP.

Anti-ultraviolet and anti-chemistry corrosion.

Anti-aging and anti-pulverization.

Long service life.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

Easy to maintain.

High strength.

Long service life.

Easy to install.

Good light transmittance.

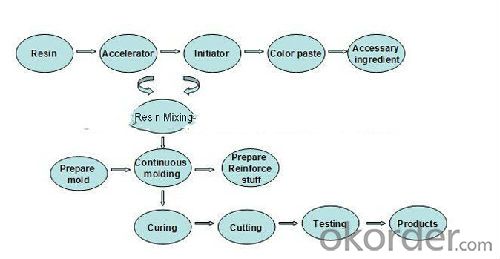

Production Process

Specification

Physical properties:

| Tensile strength | 80-100Mpa |

| Flexural strength | 0-110 Mpa |

| Density | 1.4-1.6g/cm³ |

| Pasteur | ≥40 |

| Heat conductivity factor | 0.67-0.96kv/m.h.°C |

| Temperature range | -40°C—+60°C |

| Water absorption | 24 hours ≤0.32% |

| Wind loading rating | below 8 levels |

| Curing degree | ≥82% |

Product classification:

Plate type | thickness(mm) | width(mm) | |

Flat plate | 0.7-4.0 | ≤1400 | |

Sine wave | 0.7-4.0 | ≤1200 | |

Trapezoidal wave | 0.7-4.0 | Mating with pressure plate | |

Fire resistance | Ordinary type | ||

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q:Can FRP roofing panels be used for pergolas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for pergolas. FRP panels are durable, lightweight, and resistant to corrosion, making them an excellent choice for outdoor structures like pergolas. They provide protection from the elements while allowing natural light to filter through, creating a comfortable and inviting outdoor space. Additionally, FRP panels are easy to install and maintain, making them a practical choice for pergolas.

- Q:Can FRP roofing panels be installed over metal roofs?

- Yes, FRP roofing panels can be installed over metal roofs. However, it is important to ensure proper preparation and compatibility between the two materials. The metal roof should be thoroughly cleaned and any loose or damaged sections repaired before installing the FRP panels. Additionally, proper insulation and ventilation should be considered to prevent condensation and maintain the longevity of the roof. It is recommended to consult with a professional roofer or manufacturer for specific guidelines and installation procedures.

- Q:Are FRP roofing panels available in different profiles or styles?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are available in different profiles or styles. These profiles or styles refer to the shape, design, and appearance of the panels. Common profiles of FRP roofing panels include corrugated, flat, and standing seam. Corrugated FRP roofing panels have a series of ridges and grooves, giving them a wavy appearance. They are commonly used for agricultural buildings, warehouses, and industrial structures. Flat FRP roofing panels have a smooth and even surface, resembling traditional roofing materials such as shingles or metal sheets. They are often used in residential and commercial applications. Standing seam FRP roofing panels have raised seams that interlock together, creating a visually appealing and weather-resistant roof surface. They are popular for architectural projects and buildings that require a modern, sleek aesthetic. In addition to these standard profiles, FRP roofing panels can also be customized to meet specific project requirements. This includes adjusting the thickness, length, and width of the panels, as well as incorporating different colors and finishes. It is important to note that the availability of different profiles or styles may vary depending on the manufacturer or supplier. Therefore, it is recommended to consult with a professional or supplier to determine the range of profiles or styles available for FRP roofing panels.

- Q:Are FRP roofing panels suitable for residential balconies or terraces?

- Yes, FRP roofing panels are suitable for residential balconies or terraces. FRP (Fiberglass Reinforced Plastic) roofing panels offer durability, weather resistance, and low maintenance, making them a suitable choice for outdoor spaces. These panels are lightweight, easy to install, and provide excellent protection against UV rays, moisture, and corrosion. Additionally, FRP roofing panels can be designed to mimic the appearance of traditional roofing materials, enhancing the aesthetics of residential balconies or terraces.

- Q:Are FRP roofing panels lightweight?

- Yes, FRP roofing panels are lightweight.

- Q:Do FRP roofing panels require any specific tools for installation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require specific tools for installation. Some common tools that may be needed include a power drill with appropriate drill bits, a saw for cutting the panels to size, a tape measure, a level for ensuring proper alignment, a caulking gun for applying sealant, screws or nails for securing the panels in place, and a ladder or scaffolding for accessing the roof. It is important to use the correct tools to ensure a proper and secure installation of FRP roofing panels.

- Q:Can FRP roofing panels be used in high-traffic areas?

- Yes, FRP roofing panels can be used in high-traffic areas. FRP (Fiberglass Reinforced Plastic) roofing panels are known for their durability and strength, making them suitable for areas with heavy foot traffic. They are resistant to impact, chemicals, and UV rays, making them a reliable choice for high-traffic environments. Additionally, FRP panels can withstand harsh weather conditions, making them an ideal option for outdoor spaces that experience heavy use.

- Q:Are FRP roofing panels suitable for concert venues or music festivals?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for concert venues or music festivals. FRP panels offer several advantages that make them an excellent choice for these types of venues. Firstly, FRP panels are lightweight yet sturdy, making them easy to install and transport. This is particularly beneficial for temporary structures such as stages or outdoor concert venues that need to be set up and taken down quickly. Additionally, their light weight reduces the need for heavy support structures, saving time and money during construction. Secondly, FRP panels are highly durable and weather resistant. They can withstand extreme temperatures, UV radiation, and moisture, ensuring that they can endure the rigors of outdoor events. This durability makes FRP panels a reliable choice for concert venues or music festivals, where exposure to the elements is inevitable. Furthermore, FRP panels offer excellent acoustic properties. They can effectively absorb and dampen sound, reducing echoes and improving the overall acoustics of the venue. This is crucial for concert venues or music festivals, where sound quality is paramount to ensure an enjoyable experience for the audience. In terms of aesthetics, FRP panels can be customized to fit the desired look and feel of the venue. They are available in various colors, finishes, and textures, allowing for creative designs that align with the atmosphere of the event. Whether it's a modern, sleek concert venue or a rustic outdoor festival setting, FRP panels can be tailored to suit the aesthetic requirements. Lastly, FRP panels are cost-effective compared to other roofing materials. Their long lifespan, low maintenance requirements, and energy efficiency make them a cost-efficient option for concert venues or music festivals. The reduced need for ongoing repairs or replacements translates into significant cost savings over time. In conclusion, FRP roofing panels are indeed suitable for concert venues or music festivals. Their lightweight nature, durability, acoustic properties, aesthetic customization options, and cost-effectiveness make them an excellent choice for these types of venues.

- Q:Can FRP roofing panels be used for architectural designs?

- Yes, FRP (Fiber Reinforced Plastic) roofing panels can be used for architectural designs. FRP panels are versatile and can be molded into various shapes and sizes, making them suitable for creating unique and aesthetically pleasing architectural designs. These panels can be used for roofing applications in both residential and commercial buildings, providing durability, strength, and resistance to weathering. Additionally, FRP panels come in a variety of colors and finishes, allowing architects to incorporate them seamlessly into their designs. Moreover, FRP roofing panels are lightweight, making them easy to install and reducing the structural load on the building. Overall, FRP roofing panels are a viable option for architectural designs, offering both functional and aesthetic benefits.

- Q:Are FRP roofing panels prone to cracking from heavy rain?

- No, FRP (Fiberglass Reinforced Plastic) roofing panels are not prone to cracking from heavy rain. FRP roofing panels are known for their durability and resistance to various weather conditions, including heavy rain. The composition of FRP panels, with a combination of fiberglass and plastic, makes them highly resistant to water damage. They have excellent water repellent properties and do not absorb water, which reduces the risk of cracking or warping. However, it is important to ensure proper installation and maintenance of the FRP roofing panels to maximize their lifespan and prevent any potential issues.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Reinforce Plastic Sheet Panel with 2.0 mm Thinkness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords