Steel I Beam Bar IPE for Structure Construction Normal Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel I Beam Bar IPE Description:

Steel I beam bar IPE is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel I beam IPE is usually made of structural steel and is used in construction and civil engineering. The web for Steel I beam IPE resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel I Beam IPE theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel I Beam Bar IPE Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Steel I Beam Bar IPE Images:

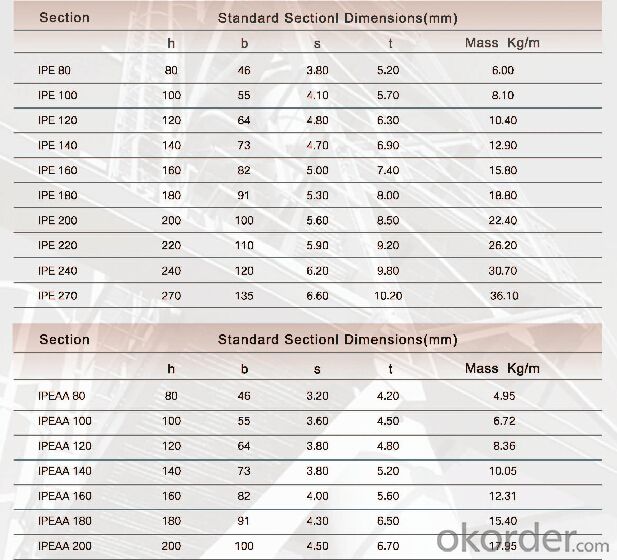

4. Steel I Beam Bar IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q:What are the different types of steel finishes available for I-beams in renovations?

- When renovating, there are various options for steel finishes for I-beams, each having its own unique qualities and aesthetic appeal. Some commonly used finishes include: 1. Mill Finish: This basic finish is achieved by hot rolling the steel in the mill without any additional treatment or coating. It has a slightly rough, dark gray surface and is typically used in industrial or structural applications where aesthetics are not a top priority. 2. Painted Finish: I-beams can be painted with different coatings to protect against corrosion and enhance their appearance. Paint options range from basic primers to more durable and weather-resistant choices like epoxy or polyurethane coatings. Painted finishes can be customized to match the overall color scheme of the renovation project. 3. Galvanized Finish: Galvanizing is a popular method that involves coating the steel with a layer of zinc to safeguard it from rust and corrosion. Galvanized I-beams have a distinctive silver-gray appearance and are commonly used in outdoor or high-moisture environments, such as bridges, balconies, or coastal construction projects. 4. Powder Coated Finish: Powder coating is a dry finishing process where powdered paint is applied to the steel's surface. The powder is then heated and fused to create a smooth and durable finish. Powder coating offers a wide range of color options, excellent corrosion resistance, and a uniform appearance, making it a popular choice for architectural and decorative applications. 5. Stainless Steel Finish: For high-end renovations, stainless steel I-beams are often preferred due to their superior corrosion resistance and modern, sleek look. The steel is typically polished to achieve a reflective surface, giving it a shiny and luxurious finish. Stainless steel finishes are commonly found in upscale residential and commercial projects like restaurants, hotels, and modern homes. When selecting the appropriate steel finish for I-beams, it is crucial to consider the specific requirements of the renovation project, including the desired level of corrosion resistance, aesthetic preferences, and budget constraints. Consulting with a structural engineer or steel supplier can help ensure the best choice for your specific needs.

- Q:How do steel I-beams handle lateral loads?

- The inherent structural shape and material properties of steel I-beams enable them to effectively handle lateral loads. The flanges and web of an I-beam contribute to its resistance against lateral forces. Positioned at the top and bottom of the beam, the wider and thicker flanges provide a larger surface area for distributing the lateral load, effectively preventing bending and deformation. In addition, steel possesses exceptional strength and stiffness properties, rendering it highly resistant to lateral loads. Consequently, when subjected to a lateral force, the steel I-beam remains resistant to deformation and retains its original shape due to the material's strength and rigidity. To further enhance the steel I-beam's ability to handle lateral loads, it is possible to implement additional measures. This may involve bracing the beams with diagonal or horizontal supports, which serve to stabilize the structure and prevent excessive lateral movement. By incorporating these bracing elements, the overall resistance of the steel I-beam system against lateral loads is further heightened. In conclusion, the structural shape and material properties of steel I-beams make them well-suited for handling lateral loads. The specific design of the I-beam, coupled with the strength and stiffness of steel, enables it to resist bending and deformation caused by lateral forces.

- Q:What are the different types of steel coatings for I-beams?

- I-beams can be coated with various types of steel coatings that serve different purposes. These coatings aim to enhance the durability and longevity of the steel, improve its resistance to corrosion, enhance its aesthetic appearance, and provide additional protection against fire. One commonly used coating is hot-dip galvanizing, which involves immersing the steel beam in molten zinc. This coating offers robust and long-lasting protection against corrosion, making it suitable for outdoor or high-moisture environments. It acts as a barrier, preventing moisture from reaching the steel surface and reducing the risk of rust formation. Another option is epoxy-based paint, which can be applied as a powder or liquid and cured through a chemical reaction. Epoxy coatings provide excellent protection against corrosion, chemicals, and abrasion. They are often used in industrial settings or environments with harsh conditions. Thermal spray coatings, such as zinc or aluminum coatings, are also available. These coatings are created by melting the coating material and spraying it onto the steel beam. They provide a thick layer of protection against corrosion, wear, and heat. They are commonly used in applications where high temperatures or extreme conditions are expected. For fire-resistant applications, specialized coatings are available. These coatings are designed to delay or prevent the spread of fire by creating a barrier between the steel and flames. They can be intumescent coatings, which expand when exposed to heat, or cementitious coatings, which form a protective layer of cement-like material. Ultimately, the choice of steel coating for I-beams depends on specific requirements such as environmental conditions, expected lifespan, and desired level of protection. Seeking professional advice or consulting with a steel supplier can help determine the most suitable coating for a particular project.

- Q:How much weight can steel I-beams support?

- The amount of weight steel I-beams can support depends on various factors such as the size, shape, and material composition of the beam, as well as the span length and load distribution. Steel I-beams are commonly used in construction due to their high strength and load-bearing capacity. The weight they can support can range from a few hundred pounds to several tons. To determine the specific weight capacity of a steel I-beam, structural engineers use complex calculations and consider factors such as the bending moment, shear force, and deflection. These calculations ensure that the beam can safely support the intended load without experiencing excessive stress or deformation. It is crucial to consult a qualified structural engineer or refer to the relevant design codes and standards for accurate and precise weight capacity information. These professionals can analyze the specific requirements of the project and consider all relevant variables to determine the appropriate steel I-beam size and configuration needed to safely support the desired weight.

- Q:What are the considerations for thermal insulation when using steel I-beams?

- When utilizing steel I-beams, there are several factors to consider in terms of thermal insulation. 1. Steel Conductivity: Steel possesses high conductivity, meaning it has the ability to transfer heat rapidly. This can result in significant heat loss or gain through the steel I-beams, depending on the temperature difference between the building's interior and exterior. Therefore, it is crucial to select insulation materials with low thermal conductivity to minimize heat transfer through the steel beams. 2. Compliance with Building Codes: It is imperative to adhere to local building codes and regulations regarding thermal insulation requirements. These codes often specify minimum thermal resistance (R-value) or U-value requirements that must be met to ensure energy efficiency and occupant comfort. The choice of insulation for steel I-beams should meet or exceed these requirements. 3. Proper Insulation Placement: Optimal placement of insulation is vital to maximize thermal efficiency. Insulating the exterior side of the steel I-beams aids in preventing thermal bridging, which occurs when heat bypasses the insulation through the steel beams, resulting in energy loss. Insulation can also be positioned between the flanges and web of the I-beams to further enhance thermal performance. 4. Effective Moisture Management: Steel I-beams have the potential to condense moisture due to temperature differences between the building's interior and exterior. This moisture can lead to corrosion and diminish the effectiveness of the insulation. Therefore, it is important to incorporate moisture barriers or vapor retarders to prevent moisture infiltration and manage vapor diffusion. 5. Ensuring Fire Safety: Although steel is a non-combustible material, it can lose strength at high temperatures. Hence, it is crucial to select insulation materials with excellent fire resistance properties to safeguard the steel I-beams in the event of a fire. Fire-rated insulation options should be considered to ensure the overall safety of the structure. 6. Structural Considerations: Adding insulation may increase the thickness or alter the dimensions of the steel I-beams, which can have implications for structural design. It is vital to consult with structural engineers to ensure that the insulation does not compromise the load-bearing capacity or integrity of the steel I-beams. To summarize, when using steel I-beams, it is important to consider minimizing thermal conductivity, complying with building codes and regulations, proper insulation placement, effective moisture management, ensuring fire safety, and accounting for structural implications. By addressing these considerations, the thermal performance of a building can be optimized, resulting in improved energy efficiency and occupant comfort.

- Q:Can steel I-beams be used for green or sustainable building projects?

- Green or sustainable building projects can indeed utilize steel I-beams. Steel possesses high recyclability, and incorporating recycled steel into I-beam construction can considerably diminish the environmental impact of a building endeavor. Furthermore, steel is a durable material with a lengthy lifespan, enabling structures constructed with steel I-beams to endure for decades, thus minimizing the necessity for frequent repairs and replacements. Additionally, steel I-beams exhibit immense strength and can bear substantial loads, enabling the creation of more flexible and efficient designs that optimize space and energy utilization. Moreover, steel's fire-resistant properties enhance a building's safety and resilience. Ultimately, integrating steel I-beams into green or sustainable building projects contributes to the reduction of carbon emissions, conservation of resources, and the development of environmentally friendly and energy-efficient structures.

- Q:How do steel I-beams contribute to the overall durability and longevity of a renovation project?

- Steel I-beams contribute to the overall durability and longevity of a renovation project in several ways. Firstly, steel I-beams are known for their exceptional strength and structural integrity. They have a high load-bearing capacity, allowing them to support heavy loads and resist bending or warping. This strength and stability make them ideal for supporting the weight of floors, walls, and roofs in a renovation project, ensuring that the structure remains stable and secure for many years to come. Additionally, steel is highly resistant to many environmental factors that can deteriorate other materials over time. Unlike wood, for example, steel I-beams are not susceptible to rot, termites, or mold, which can compromise the structural integrity and durability of a renovation project. They are also resistant to fire, making them a safer choice in terms of protecting the building and its occupants. Moreover, steel I-beams have a long lifespan and require minimal maintenance. They do not warp or shrink due to moisture or temperature changes, reducing the need for costly repairs or replacements down the line. Steel is also not prone to corrosion when properly coated, ensuring that the I-beams remain strong and durable even in harsh environments. Lastly, steel I-beams offer flexibility in design and construction. Their shape allows for open, spacious interiors without the need for many supporting columns or walls. This flexibility not only enhances the aesthetic appeal of the renovation project but also provides the opportunity for future modifications or additions if needed. In conclusion, steel I-beams contribute significantly to the durability and longevity of a renovation project. Their strength, resistance to environmental factors, long lifespan, low maintenance requirements, and design flexibility make them an ideal choice for supporting structures and ensuring the overall stability and longevity of any renovation project.

- Q:Can steel I-beams be used for religious buildings?

- Indeed, religious buildings can certainly make use of steel I-beams. Steel, being a versatile and durable material, offers numerous advantages in construction. Its strength, load-bearing capabilities, and resistance to fire and corrosion make it an ideal choice for supporting the structural framework of religious buildings, such as churches, temples, mosques, or synagogues. The steel I-beams provide the necessary structural integrity to bear the weight of the building, including the roof and any additional floors. They are capable of spanning long distances, allowing for open and spacious interior designs. This is particularly desirable in religious buildings, as it accommodates large gatherings and creates a sense of awe and reverence. Moreover, steel's fire-resistant properties add an extra level of safety, which is crucial in religious buildings where large crowds may gather. Its resistance to corrosion also ensures the longevity and durability of the structure, resulting in reduced maintenance costs over time. Furthermore, steel's versatility allows for innovative architectural designs that can reflect the cultural or spiritual aspects of a particular faith. Steel I-beams can be easily incorporated into both traditional and contemporary architectural styles, providing flexibility in design choices. In conclusion, due to their strength, durability, fire resistance, and versatility, steel I-beams are definitely suitable for religious buildings. They not only provide the necessary structural support but also allow for spacious and architecturally appealing designs that cater to the needs and aesthetic preferences of various faith communities.

- Q:How do steel I-beams compare to wooden beams in terms of strength and durability?

- Unlike wooden beams, steel I-beams are known for their exceptional strength and durability. Steel surpasses wood in terms of tensile strength, enabling it to withstand heavier loads without any risk of breaking or bending. Consequently, steel I-beams are the perfect choice for supporting immense weights or spanning extensive distances, such as in the creation of skyscrapers or bridges. On the other hand, wood possesses a lower tensile strength and is more susceptible to warping, splitting, and rotting over time. While wooden beams can still offer some level of strength and durability, they are generally limited in their capacity to bear heavy loads and maintain longevity when compared to steel. Furthermore, wooden beams may require more frequent maintenance and protection from moisture or insect damage. Regarding durability, steel I-beams exhibit exceptional resistance against fire, pests, and environmental factors such as moisture or fluctuations in temperature. Unlike wood, steel does not decay or degrade over time, making it an enduring option for providing structural support. Conversely, wooden beams are more prone to fire damage, termite infestations, and decay. Overall, steel I-beams outperform wooden beams in terms of strength and durability, establishing them as the preferred choice for numerous construction projects that demand maximum load-bearing capacity and long-term structural integrity.

- Q:How do steel I-beams perform in terms of seismic resistance?

- Steel I-beams are known for their exceptional seismic resistance. The structural design of I-beams allows them to withstand the forces generated during an earthquake. The shape of I-beams provides a high strength-to-weight ratio, making them capable of supporting heavy loads while remaining flexible enough to absorb and dissipate seismic energy. One of the key advantages of steel I-beams in terms of seismic resistance is their ductility. Ductility refers to a material's ability to deform under stress without fracturing. During an earthquake, the ground shakes, causing the building to vibrate. Steel I-beams can flex and bend without breaking, absorbing the seismic energy and preventing catastrophic failures. This ability to deform and absorb energy helps to distribute the forces generated by an earthquake throughout the structure, minimizing localized damage. Additionally, steel I-beams can be easily reinforced and retrofitted to enhance their seismic resistance. By adding additional bracing, cross-members, or steel plates, the overall stiffness and strength of the I-beams can be increased, improving their performance during an earthquake. Furthermore, steel is a homogeneous material with consistent properties, which allows for accurate engineering calculations and predictable behavior under seismic loads. This predictability enables engineers to design structures that meet the necessary safety standards for seismic resistance. Overall, steel I-beams are widely recognized for their excellent seismic resistance. Their strong and flexible nature, combined with the ability to reinforce and retrofit them, make them a preferred choice for earthquake-prone areas, ensuring the safety and stability of buildings during seismic events.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel I Beam Bar IPE for Structure Construction Normal Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords