Steel H Beam for Building with Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cheap Price Steel H Beam for Building Details

Place of Origin: | China (Mainland) | Grade: | Q235 | Technique: | Hot Rolled |

Thickness: | 6-12mm | Application: | Steel Building Structure | Length: | 12m |

Standard: | JIS | Flange Width: | 50-400mm | Flange Thickness: | 7-28mm |

Web Width: | 50-400mm | Web Thickness: | 5-21mm | Brand Name: | AJ |

Model Number: | HB400 | Color: | Black | shape: | H |

Packaging & Delivery

Packaging Detail: | in bundle with steel wire |

Delivery Detail: | within 15 days after receipt of deposit |

Cheap Price Steel H Beam for Building Advantages

Steel H beam is more flexible in use and save more material than traditional I beam.

Steel H beams are widely used in the construction industry and are available in a variety of standard sizes.

H steel beam may be used both as beams and as columns.It may be used both on their own, or acting compositely with another material, typically concrete.

H shape steel beam has wider flanger than normal I beam,more stable to use.

The construction time of steel h beam will be twice or more faster than use concrete.

Cheap Price Steel H Beam for Building Specifications

Height*Width (mm) | Web thickness (mm) | Flange thickness (mm) | kg/m | Height*Width (mm) | Web thickness (mm) | Flange thickness (mm) | kg/m |

| 150*100 | 6 | 9 | 21.4 | 506*201 | 19 | 103.1 | |

| 200*150 | 6 | 9 | 31.2 | 600*200 | 10 | 15 | 95.2 |

| 250*175 | 7 | 11 | 44.1 | 11 | 17 | 106.1 | |

| 300*200 | 8 | 12 | 57.3 | 12 | 20 | 120.3 | |

| 350*250 | 9 | 14 | 79.7 | 700*300 | 13 | 20 | 166 |

| 400*300 | 10 | 16 | 107.3 | 13 | 24 | 185 | |

| 450*300 | 11 | 18 | 124 | 800*300 | 14 | 22 | 191 |

| 500*300 | 11 | 15 | 115 | 14 | 26 | 210 | |

| 11 | 18 | 129.1 | 900*300 | 16 | 28 | 243 |

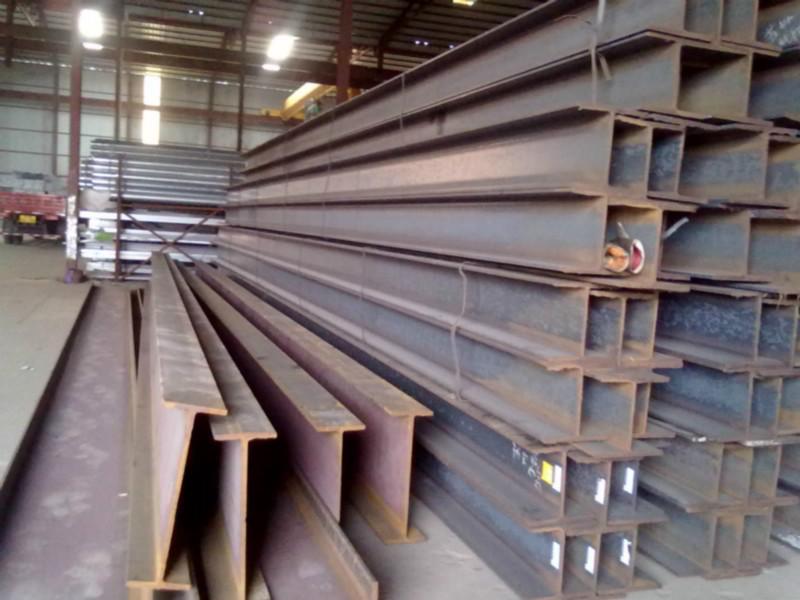

Cheap Price Steel H Beam for Building Pictures

- Q:Can steel H-beams be used in marine environments?

- Yes, steel H-beams can be used in marine environments, but they require proper protection and maintenance to prevent corrosion. Marine environments are known for their high levels of moisture, saltwater exposure, and harsh weather conditions, all of which can accelerate the corrosion process of steel. To mitigate these risks, steel H-beams used in marine environments should be made from corrosion-resistant materials, such as stainless steel or galvanized steel. Stainless steel is especially suitable for marine environments due to its high resistance to corrosion and rust. It contains a significant amount of chromium, which forms a thin, passive layer on the surface of the steel, protecting it from the corrosive effects of saltwater and moisture. Stainless steel H-beams can withstand the harsh marine environment without significant degradation, making them a popular choice for applications such as piers, bridges, and offshore structures. Galvanized steel is another viable option for marine environments. It is carbon steel that has been coated with a layer of zinc, which acts as a sacrificial barrier against corrosion. The zinc coating corrodes first, protecting the underlying steel from direct exposure to saltwater and moisture. However, galvanized steel may not be as durable as stainless steel in highly corrosive marine environments, and the protective zinc coating can wear off over time, requiring periodic maintenance and reapplication of the coating. Regardless of the type of steel used, regular maintenance and inspections are crucial to ensure the integrity of H-beams in marine environments. This includes regular cleaning to remove salt deposits, repainting or re-galvanizing as needed, and addressing any signs of corrosion or damage promptly. Additionally, proper design considerations should be made to account for the specific challenges posed by marine environments, such as tidal forces, wave impact, and temperature fluctuations. In summary, steel H-beams can be used in marine environments, provided they are made from corrosion-resistant materials like stainless steel or galvanized steel and are properly maintained. With the right precautions, these beams can withstand the harsh conditions of marine environments, making them a reliable choice for various marine structures and applications.

- Q:What are the considerations for selecting the appropriate fabrication method for steel H-beams?

- There are several factors to consider when choosing the right fabrication method for steel H-beams. These factors include the required dimensions, quality requirements, cost-effectiveness, and production volume. To begin with, the dimensions of the H-beam are crucial in determining the fabrication method. Different methods, such as hot rolling, cold bending, or welding, have their own limitations in terms of size and shape. It is important to ensure that the chosen fabrication method can meet the desired dimensions of the H-beam. Furthermore, the quality requirements of the H-beams should be carefully evaluated. This includes factors like strength, durability, and surface finish. Each fabrication method has its own impact on the final product's quality. For example, hot rolling is known for producing H-beams with superior strength and surface finish compared to cold bending. However, welding may introduce potential defects that can affect overall quality. Cost-effectiveness is another important consideration. Different fabrication methods have varying costs associated with them, including material, labor, and equipment expenses. The appropriate method should strike a balance between desired quality and fabrication costs. Lastly, the production volume also influences the choice of fabrication method. High-volume production often favors methods like hot rolling or welding, which offer higher efficiency and faster production rates. On the other hand, low-volume production allows for more flexibility in choosing methods that require more manual labor, such as cold bending. In conclusion, when selecting the right fabrication method for steel H-beams, it is important to consider dimensions, quality requirements, cost-effectiveness, and production volume. Finding a balance between these factors ensures the desired outcome in terms of both quality and cost.

- Q:How do steel H-beams perform in high wind areas?

- Steel H-beams have gained a reputation for possessing exceptional strength and durability, making them a favored option for construction in regions with high wind conditions. These beams are specifically designed to withstand extreme weather, including powerful winds, by providing a sturdy and stable framework for buildings and structures. The structural design of steel H-beams allows for the efficient distribution of wind load throughout the entire structure, which minimizes the potential for any damage. The unique shape of the H-beam enables it to bear heavier loads, as it can better resist the bending and twisting forces caused by high winds. This ensures that the beams remain stable, preventing any structural failures or collapses. Moreover, steel H-beams are commonly crafted from high-strength steel alloys, which further enhances their ability to endure high winds. These alloys possess superior tensile strength and elasticity, enabling the beams to flex and absorb the energy from wind gusts without permanently distorting or fracturing. This flexibility aids in dissipating the force of the wind and reducing overall stress on the structure. Additionally, steel H-beams are frequently installed as part of a comprehensive structural system that incorporates other components, including bracing, connectors, and fasteners. These elements work together to enhance the performance of the beams in high wind regions. Properly engineered connections and bracing systems effectively transfer the wind load to the foundation, ensuring the overall stability and integrity of the structure. In conclusion, steel H-beams are well-suited for regions with high wind conditions due to their strength, rigidity, and durability. Their efficient load distribution capabilities, high-strength alloys, and compatibility with other structural components make them a reliable choice for buildings and structures in areas prone to strong winds.

- Q:Can steel H-beams be used for column supports?

- Certainly! Column supports can indeed utilize steel H-beams. These H-beams are frequently employed in construction due to their robustness and ability to bear heavy loads. They serve as structural supports in various structures such as buildings and bridges, including column supports. Their shape and material strength lend to exceptional support and stability. The design of H-beams ensures an even distribution of weight and load, rendering them suitable for deployment in column supports. Moreover, steel H-beams exhibit great durability and resistance to bending or warping, thus being a dependable option for sustaining substantial loads.

- Q:What are the different bolt sizes used for steel H-beams?

- Steel H-beams commonly utilize various bolt sizes, which depend on the particular application and load requirements. M12, M16, M20, and M24 are among the most frequently employed bolt sizes for steel H-beams. The selection of these bolt sizes is determined by the desired strength and load capacity of the specific steel H-beam structure. Furthermore, the length of the bolts can vary depending on the thickness and width of the H-beam. To guarantee optimal strength and stability, it is crucial to refer to engineering specifications and calculations when determining the suitable bolt sizes for a given steel H-beam structure.

- Q:Can steel H-beams be used in seismic-resistant construction?

- Yes, steel H-beams can be used in seismic-resistant construction. Steel H-beams are commonly used in earthquake-resistant structures due to their high strength and ductility. Their rigid structure helps withstand seismic forces, and they can be designed to provide the necessary stiffness and flexibility required to resist intense shaking during earthquakes. Additionally, steel H-beams can be easily fabricated and connected, making them a popular choice for seismic-resistant construction.

- Q:H steel compared with ordinary steel in the end what are the advantages and disadvantages?

- Structure: steel structure with high stability of hot-rolled H steel based, its scientific and reasonable structure, good flexibility and plasticity, high structure stability, suitable for bearing vibration and impact load of building structure, strong ability to resist natural disasters, especially suitable for some building structures with the earthquake. According to statistics, in the world of 7 or more devastating earthquake disaster, the H steel based steel structure damage to the smallest extent.

- Q:What are the energy efficiency benefits of using steel H-beams?

- There are several energy efficiency benefits of using steel H-beams in construction projects. Firstly, steel is a highly sustainable and eco-friendly material. It is a 100% recyclable material, which means that it can be reused indefinitely without any loss in quality or strength. By using steel H-beams, we reduce the need for new production and mining of raw materials, which results in significant energy savings and reduces the environmental impact of construction. Secondly, steel H-beams have a high strength-to-weight ratio. This means that they can support heavy loads while being relatively lightweight themselves. As a result, less material is required to construct buildings or structures, leading to reduced energy consumption during manufacturing and transportation. Additionally, the lightweight nature of steel H-beams allows for more efficient construction processes, resulting in time and energy savings. Furthermore, steel H-beams offer excellent durability and longevity. Steel is resistant to corrosion, fire, and pests, making it a highly resilient material. By using steel H-beams, buildings can withstand harsh weather conditions and natural disasters, reducing the need for frequent repairs or replacements. This durability translates into long-term energy savings as maintenance and replacement costs are minimized. Lastly, steel H-beams can contribute to energy efficiency through their thermal properties. Steel is a good conductor of heat, allowing for efficient temperature regulation in buildings. This means that steel H-beams can help to minimize heat loss during colder seasons and reduce the need for excessive heating, resulting in lower energy consumption and cost savings. In summary, the energy efficiency benefits of using steel H-beams include reduced energy consumption during manufacturing and transportation, minimized maintenance and replacement costs, and improved thermal insulation properties. By utilizing steel H-beams in construction projects, we can create more sustainable and energy-efficient buildings, contributing to a greener future.

- Q:I would like to ask you to do the master of steel structure, steel H steel cost per ton, how many yuan? emergency

- Installation of steel structure costs between 350-450 tons per ton.It is not enough, labor costs rise, steel installation fee of around 450, Chongqing installation fee of around 550The production fee is 800-1000, including two primers.I am a steel construction unit, 10 years of operation. Don't ask me. Give me the best answer.

- Q:Can steel H-beams be used for curtain walls?

- No, steel H-beams are not typically used for curtain walls. Curtain walls are usually constructed using lightweight materials such as aluminum or glass, which provide better insulation, aesthetics, and structural support for the exterior facades of buildings. Steel H-beams are primarily used for structural support in building frames and are not suitable for the specific requirements of curtain walls.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel H Beam for Building with Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords