JIS Standard SS400 H beams with High Quality 100mm-150mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of JIS Standard SS400 H beams with High Quality 100mm-150mm:

1. Standard: JIS 3192

2. Grade: SS400 or Equivalent

3. Length: 10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

Size and Mass of JIS Standard SS400 H beams with High Quality 100mm-150mm:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg) |

| 100*100*6.0 | 16.9 | 148*100*6.0 | 20.7 |

| 125*125*6.5 | 23.6 | 150*150*7.0 | 31.1 |

| 150*75*5.0 | 14.0 |

Packaging & Delivery of JIS Standard SS400 H beams with High Quality 100mm-150mm for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 months days from the beginning of production.

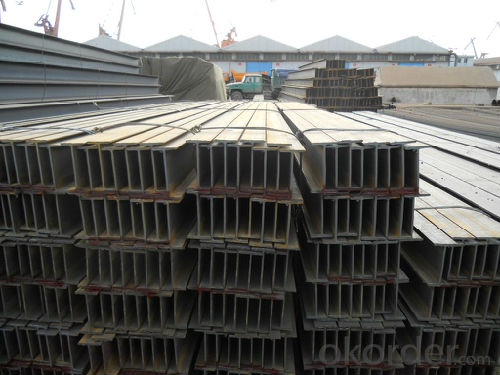

Images of JIS Standard SS400 H beams with High Quality 100mm-150mm:

* If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q:Are there any safety concerns related to steel H-beams?

- Steel H-beams present safety concerns that must be addressed. When used in construction for structural support, certain factors need to be taken into account to maintain safety. One primary concern is the potential for structural failure. Steel H-beams are subjected to various loads, including static, dynamic, and environmental forces. Without proper design, fabrication, or maintenance, they can develop weaknesses or defects that may lead to collapse or failure. Fire resistance is another safety concern. Steel H-beams, like other steel structures, are vulnerable to fire. The high temperatures during a fire can weaken the steel, reducing its load-bearing capacity. To enhance safety in fire-prone areas, fire protection measures such as fire-resistant coatings or fireproofing materials should be used. Construction or maintenance activities involving steel H-beams also pose a risk of accidents and injuries. Workers must follow safety protocols, such as wearing personal protective equipment, using proper lifting and rigging techniques, and securely fastening the beams to prevent accidents like falling or structural collapse. Lastly, the weight and size of steel H-beams can create challenges during transportation, handling, and installation. Specialized equipment and trained personnel are necessary to safely lift, move, and position these heavy beams. Failure to follow safety procedures can result in accidents, injuries, or property damage. In conclusion, although steel H-beams are commonly used and reliable for structural support, safety concerns must be addressed. Proper design, fabrication, maintenance, fire protection measures, and adherence to safety protocols are crucial to ensure their safe use in construction and related activities.

- Q:Can steel H-beams be used in data center structures?

- Data center structures can indeed incorporate steel H-beams. The utilization of H-beams is widespread in construction due to their remarkable strength, durability, and load-bearing capabilities. In the case of data centers, which accommodate hefty equipment and machinery, steel H-beams offer the essential support and stability for the infrastructure. These beams have the capacity to bear substantial loads and withstand elevated levels of stress, rendering them exceptionally suitable for data center structures. Furthermore, steel H-beams can be readily tailored and manufactured to meet precise design specifications, thus guaranteeing the structural integrity of the data center.

- Q:What are the different sizes and dimensions of steel H-beams?

- Steel H-beams come in various sizes and dimensions to accommodate different construction and engineering needs. The specific sizes and dimensions of steel H-beams can vary depending on the manufacturer and the intended use. However, some common sizes include height measurements ranging from 100mm to 1000mm, and widths ranging from 50mm to 300mm. The length of steel H-beams can also vary, typically ranging from 6 meters to 18 meters. These variations in sizes and dimensions allow for flexibility in design and construction projects.

- Q:Are steel H-beams resistant to chemical exposure?

- Steel H-beams are generally resistant to chemical exposure. Steel is known for its high durability and strength, which makes it resistant to many chemical substances. However, the level of resistance can vary depending on the specific chemicals involved and the duration of exposure. In general, steel H-beams can withstand exposure to common chemicals found in industrial and construction settings, such as oils, solvents, acids, and alkalis. They are also resistant to atmospheric corrosion, which is an advantage in outdoor applications. However, it is important to note that prolonged exposure to certain highly corrosive chemicals or extreme conditions can still have a detrimental effect on steel. Chemicals like strong acids or bases, aggressive salts, or highly oxidizing substances may cause corrosion or degradation over time. To ensure maximum resistance to chemical exposure, it is advisable to consult with professionals or experts in the field who can provide guidance on the specific chemicals involved and recommend appropriate protective coatings or treatments for the steel beams.

- Q:How do steel H-beams perform in seismic zones?

- Due to their exceptional strength and performance, steel H-beams are widely utilized in construction, including seismic zones. In areas more susceptible to earthquakes, it is vital to utilize materials that can endure the forces generated by seismic events. Steel H-beams are specifically crafted to handle these forces. Their unique shape, featuring a vertical web and horizontal flanges, grants them remarkable resistance to bending and torsion, rendering them incredibly effective in seismic zones. The vertical web functions as a support, evenly distributing the load across the beam, while the horizontal flanges resist bending and provide stability. Furthermore, steel possesses excellent ductility, the ability to deform without breaking. When subjected to seismic forces, steel H-beams can absorb and dissipate energy through their ductility, minimizing the risk of sudden failure. This property is particularly crucial in seismic zones, as it allows the structure to undergo some deformation while maintaining overall integrity. Additionally, steel H-beams are frequently utilized in conjunction with other seismic-resistant techniques, such as moment-resisting frames or base isolation systems, to further enhance their performance. These systems work in tandem to minimize the impact of seismic forces on the structure, ensuring the safety of the building and its occupants. In summary, steel H-beams exhibit exceptional performance in seismic zones. Their design, material properties, and compatibility with other seismic-resistant techniques make them a reliable choice for construction in earthquake-prone areas.

- Q:Can steel H-beams be used for supporting elevated water tanks?

- Yes, steel H-beams can be used for supporting elevated water tanks. H-beams are often used in construction for their strength and load-bearing capabilities. They provide stability and durability, making them suitable for supporting the weight of elevated water tanks.

- Q:What are the dimensions of a steel H-beam?

- The dimensions of a steel H-beam can vary depending on the specific design and manufacturer. However, in general, H-beams are characterized by their height, width, and weight per foot. The height of an H-beam refers to the vertical distance from the top to the bottom flange, while the width is the horizontal distance between the two flanges. The weight per foot indicates the amount of steel used in a linear foot of the beam. These dimensions can vary widely depending on the intended use and load-bearing requirements.

- Q:Can steel H-beams be used in the construction of airports?

- Yes, steel H-beams can be used in the construction of airports. Steel H-beams are commonly used in the construction industry for a variety of structural applications due to their strength and versatility. In airport construction, steel H-beams can be used for various purposes such as supporting the roof structure of terminal buildings, creating the framework for hangars, constructing bridges and walkways, and providing support for aircraft parking areas and runways. The use of steel H-beams in airport construction provides a durable and cost-effective solution, ensuring the structural integrity and safety of the airport infrastructure.

- Q:How do you calculate the load-bearing capacity of steel H-beams?

- The load-bearing capacity of steel H-beams can be calculated by determining the moment of inertia of the beam section and then using this value to calculate the maximum bending stress the beam can withstand. The moment of inertia is calculated based on the dimensions and properties of the H-beam section, including its height, width, and thickness.

- Q:Can Steel H-Beams be used in foundation or basement construction?

- Yes, steel H-beams can be used in foundation or basement construction. H-beams are commonly used in construction due to their strength, durability, and versatility. They can provide a solid and stable foundation for buildings, including basements. Steel H-beams are typically used in conjunction with other materials, such as concrete, to create a strong foundation or basement structure. The H-shape of the beams allows for better load distribution and increased structural stability, making them an ideal choice for these types of construction projects. Additionally, steel H-beams are resistant to weathering, corrosion, and pests, which further enhances their suitability for foundation and basement construction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JIS Standard SS400 H beams with High Quality 100mm-150mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products