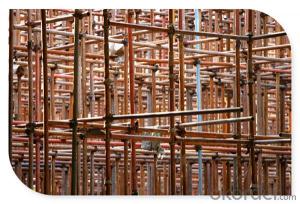

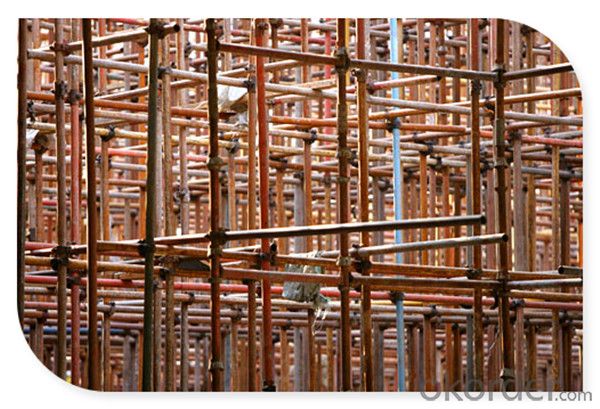

Steel Cuplock Scaffolding System for Concrete Building Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Steel Cuplock Scaffolding System for Concrete Building Construction

Name Cuplock Scaffold System Size Many sizes or as your request Main Material Q235/345 Steel Surface Treatment High Protected Painted, Powder Coating, Electric Gavenized, Hot Dip Gavenized. Color Silver, Orange, Red Certificate SGS, EN12810. Service OEM Service available MOQ 50T Payment T/T, Western Union Delivery Time 15-25 days after deposite Packing in bulk or steel pallet or as your request production capability 50 tons per day Main Market Africa, South America, the Middle East and Asia

Descriptions of Steel Cuplock Scaffolding System for Concrete Building Construction

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Steel Cuplock Scaffolding System for Concrete Building Construction

1.Cuplock scaffold system is simple in structure,including top cup,bottom cup and ledger blade.

2.Quick installation of horizontals and verticals,you can easily fit the ledger blade into the cups with a hammer.

3.Cuplock scaffold system standards are made from higher quality steel tube which allow more than 58KN load per leg.

4.Cuplock scaffold system is a multi-functional scaffolding system which is suitable for all forms of access and support structures,especially used in bridege building.

5.People can fasten joint of ledgers by putting two extra ledger blades in the cups.

6.This cuplock scaffold system are interlocked by cups and ledgers which is very safe and stable steel scaffolding system.

7.This is a heavy duty scaffold system which can load about 16tons for each cuplock scaffolding system.

8.Cuplock scaffold system can be used both interior or outerior high-rise building construction project, expecially for arc shape building such as bridge, tunnel, subway, or gym building. it's multifunctional.

9.This is a galvanized cuplock scaffold system which surface is hot dip galvanized, it can keep a longer working life.

10.Gavanized cuplock scaffold system is water-proof scaffold sysem which can prevent the air and water to damage the cups and ledgers very effectively.

11.Cuplock scaffold system can be quick to errect by interting the cuplock blade into bottom cup, then swivel the top cup to fixed it.

12.Suitable for transportation and storage: Single cuplock scaffold system standard and ledger occupy less space. Wiht no extra parts.

The Measures of Steel Cuplock Scaffolding System for Concrete Building Construction

Standard: 3000mm, 2500mm, 2000mm, 1500mm, 1000mm, 500mm.

Ledger: 3000mm, 2000mm, 1780mm, 1500mm, 1000mm, 500mm.

Diagonal brace: 3000X2000mm, 1780X2000mm, 1000X1500mm, 1000X2000mm, 1500X2000mm,

Tube specification: Φ 48.3X4.0mm, φ 48.0 X3.25mm, φ 48.0 X3.0mmFAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:Who knows how much the amount of the main material used to take one square metre of conventional double row scaffolding (within 12 meters). For example, how many kilograms of steel pipe, the number of fasteners. The content of the quota is low, I am also very confused, to the completion of the work of the scaffolding rental fees. Very urgent, I hope to know the user to answer. Accident report

- I am also very confused, to the completion of the work of the scaffolding rental fees. Very urgent, I hope to know the user to answer. Landlord can refer to

- Q:THIS METAL SCAFFOLDING IS CONNECTED TO EARTH.Need 2 more questions to be answered:1.Is he going to be electrocuted if he wasn't holding the metal scaffolding?2.will the current flow through him or through the wire in both cases?

- First of all, are you working with AC ( alternating current - like a house) or DC ( direct current - like a car)? Assuming you are working with AC, then: Which wire are you holding? This again is assuming 120 vac - Bare copper ( ground) White ( neutral ) or Black ( Hot ) If you have a bare copper ground wire or the White insulated wire you will be fine. If you have the Black insulated wire in your hand then you are going to have a bad day. Yes to the first question Yes to the second question ( I would hope he was smart enough to let go before being too badly zapped) Both is the answer to the third question, as the person is basically an extension of the circuit - being burnt up - until he touches earth (ground) allowing the current to seek ground. All in all I would say leave any exposed wires alone until you have a professional with a multi meter check it out first. If this is in a commercial ( business) setting the voltages are much higher, not to mention it is most likely 3 phase - so watch out. All colors are referenced for the United States.

- Q:scaffold, where to buy?

- Unless you need it constantly it might be cheaper to rent as most contractors do. Home Depot, Safeway Rentals or most any tool and equipment rental outfit rents it at pretty reasonable rates.

- Q:does anyone know where i can find dimmesdale's confession (at night) of his sins upon the scaffold.?

- Dimmesdale does not confess to his crimes on the scaffold at night, but he does meet with Hester and little Pearl on the scaffold while Chillingsworth watches. (pg. 220) His public confession comes at the end of the book during the day time and then he dies.(pg. 367) Follow the link I have attached and type in the page numbers in the little box near the top of the page.

- Q:I want to get something pierced. My mom wont let me get anything on my face pierced but she will allow ear and body piercings. I thought about a belly ring but everyone has one amd i'm very skinny and scared it'd rip out. so i've been looking at ear piercings and really like a Targus piercing or a scaffold. But i don't know anything about them really. If you could which one is more painful, problems with them etc. please help, thank you

- If you want to be different AND have something that looks really cute, get a micro dermal. Either on your collar bone, or lower back dimples if you have cute ones! Good luck hun!

- Q:What's an antonym for the word scaffold?

- Since a scaffold is a bridge/ladder/support used to allow you to span the gap between you and and object you wish to reach, I'd go with barrier.

- Q:What are the main safety problems when dismantling the scaffold

- 1, all the rods and fasteners in the demolition of the separation, not on the rod attached fasteners or two rods connected to the ground.2, all the feet of the hand, should be erected from the outside of the handle, in order to prevent the feet and garbage from falling.

- Q:Rather than buy tensile steel rods to reinforce concrete I wonder whether I can effectively recycle scaffold tubes that are presently on my roof.

- inthisall.chills.it A very informative website, kindly stay a minute in website and enter you email address for getting your answer.

- Q:I would like a scaffold piercing, but my parents aren't going to let me have two cartilage piercings at once. So, can they be done separately, as in weeks apart?

- Technically yes but it is better to have them done at the same time so the holes are aligned properly. It is better to get them done at the same time, as the second piercing will be less painful because you are all adrenalin-ed up! Probably cheaper too.

- Q:In the calculation of the bearing capacity of the scaffold, what is the axial force produced by the "N g2k" - the standard value of the component?The calculation formula for force rod scaffold N/ psi A+Mw/W = fWhere N=1.2 (Ng1k+Ng2k) +0.85*1.4 Sigma NqkThe specification of N g2k is explained in terms of the axial force generated by the standard values of the component fitting,It is how to understand, specifically refers to what? That is to say, what is the standard value of the component?Please master all trouble, thank you generous with your criticism!

- Is to produce weight between each vertical rod scaffolding force

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Cuplock Scaffolding System for Concrete Building Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords