Steel billet for rebar steel material from china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 24983 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into

more functional shapes and sizes. While they have already been put in the furnace, they still require a series

of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in

hardware stores, or used for different applications. The unformed billets, however, can be used in striking

currency such as coins and as reserves, similar to gold bars.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the

support foundation pile manufacturing.

Qaulity:own factory, stable quality

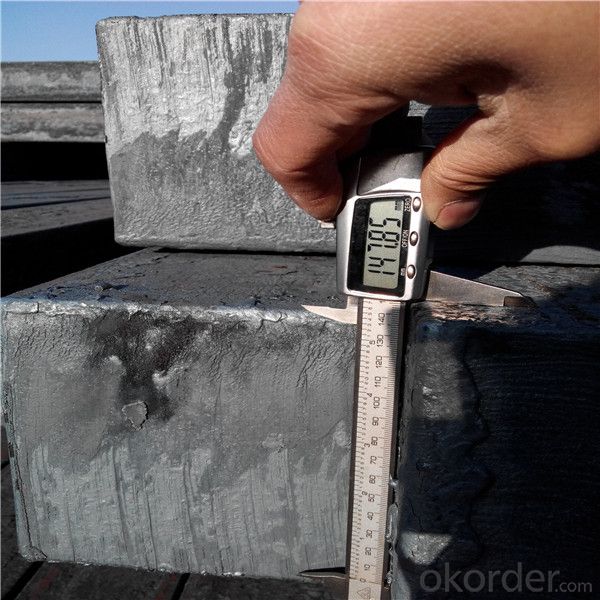

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Payment terms: 100%Irrevercable L/C at sight or T/T

.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q:What are the different methods of steel billet surface cleaning?

- Steel billet surface cleaning can be achieved through various methods, each with its own set of advantages and disadvantages. Some commonly used methods include: 1. Shot Blasting: By propelling small metallic or non-metallic particles at high speeds onto the billet surface, rust, scale, and other contaminants are effectively removed. Shot blasting is a quick and efficient method for cleaning large surfaces. However, it may result in surface roughness and may not be suitable for all types of steel. 2. Acid Pickling: This method involves immersing the steel billet in an acid solution, typically hydrochloric or sulfuric acid, to eliminate scale and rust. The acid reacts with the surface contaminants, dissolving them and leaving a clean surface. Acid pickling is particularly effective in removing stubborn scale and rust. However, it requires careful handling of corrosive acids and proper waste disposal. 3. Mechanical Cleaning: Mechanical cleaning methods utilize abrasive tools or brushes to physically scrub the billet surface. This can be done manually or with the assistance of machinery. Mechanical cleaning effectively removes loose contaminants and scale. However, it may not be suitable for heavily rusted or firmly adhered contaminants. 4. High-Pressure Water Jetting: This method employs high-pressure water jets to cleanse the billet surface. The force of the water effectively removes scale, rust, and other contaminants. High-pressure water jetting is environmentally friendly as it does not involve the use of chemicals. However, it may not be as effective in removing heavy scale or rust. 5. Ultrasonic Cleaning: Ultrasonic cleaning entails immersing the steel billet in a tank filled with a cleaning solution and subjecting it to high-frequency ultrasonic vibrations. These vibrations generate tiny bubbles in the cleaning solution, which collapse on the billet surface, effectively eliminating contaminants. Ultrasonic cleaning is highly efficient in removing even microscopic particles and can reach complex geometries. However, it may not be suitable for large-scale cleaning operations. Each method possesses its own unique strengths and limitations. The selection of a specific method depends on factors such as the type and condition of the surface contaminants, time and cost constraints, and the desired surface finish.

- Q:What is the role of steel billets in the manufacturing of construction cranes?

- Steel billets play a crucial role in the manufacturing of construction cranes as they serve as the raw material for the production of various crane components. These billets are essentially semi-finished steel products that are cast into a specific shape and size, usually in a rectangular or square form. One of the primary uses of steel billets in crane manufacturing is for the production of structural members such as beams, columns, and braces. These components provide the necessary strength and stability to support the weight of the crane and the loads it carries. Steel billets are chosen for their high strength and durability, allowing the crane to withstand heavy loads and adverse working conditions. Moreover, steel billets are also used to manufacture the boom, jib, and other lifting mechanisms of the crane. These components are subjected to significant stress and forces during crane operation, and steel billets' superior mechanical properties make them ideal for ensuring the structural integrity and longevity of the crane. Additionally, steel billets are utilized in the fabrication of the crane's counterweights. Counterweights are essential to balance the weight of the load being lifted and prevent the crane from tipping over. By using steel billets, manufacturers can produce counterweights that are heavy enough to counterbalance the loads without compromising the overall stability and safety of the crane. Furthermore, steel billets are often used in the production of other crane parts such as pins, bolts, and connectors. These small but critical components contribute to the overall performance and functionality of the crane, ensuring smooth operation and structural integrity. Overall, steel billets serve as the building blocks for the manufacturing of construction cranes, providing the necessary strength, durability, and stability required for these heavy-duty machines. Without steel billets, it would be nearly impossible to produce cranes capable of lifting heavy loads and withstanding the demanding conditions of construction sites.

- Q:What is the maximum length of a steel billet?

- The maximum length of a steel billet can vary depending on various factors such as the manufacturing process, equipment capabilities, and specific industry requirements. In general, steel billets can range in length from a few inches to several meters. However, it is important to note that longer billets are often more challenging to produce and handle due to their increased weight and potential for deformation. Therefore, the maximum length of a steel billet is typically determined by practical considerations and operational limitations within the steel industry.

- Q:How do steel billets contribute to the overall sustainability of a product?

- Steel billets contribute to the overall sustainability of a product by enabling efficient use of resources and minimizing waste. They are produced from recycled steel, reducing the need for extracting raw materials and conserving energy. By providing a high-quality starting material for various steel products, billets promote durability and longevity, reducing the need for frequent replacements. Additionally, their uniform shape and size facilitate efficient manufacturing processes, resulting in reduced energy consumption and emissions.

- Q:How do steel billets differ from steel ingots?

- Steel billets and steel ingots differ in terms of their shape and size. Steel billets are typically long and narrow, resembling a thick bar or rod, while steel ingots are larger and have a rectangular or square shape. Additionally, steel billets are usually smaller in size compared to steel ingots. Moreover, steel billets are often produced through continuous casting, while steel ingots are typically made through the traditional method of pouring molten steel into molds.

- Q:How do steel billets contribute to the manufacturing of water and wastewater treatment equipment?

- Steel billets are used in the manufacturing of water and wastewater treatment equipment as they serve as the raw material for various components such as pipes, tanks, and structural supports. These billets are melted and shaped into the required forms, ensuring the durability and strength of the equipment. Additionally, steel billets can be further processed to create corrosion-resistant coatings, ensuring the longevity and reliability of the equipment in harsh water and wastewater environments.

- Q:What are the main factors affecting the machined surface quality of steel billets?

- There are several main factors that significantly affect the machined surface quality of steel billets. These factors include: 1. Cutting Speed: The cutting speed, which is the speed at which the tool moves across the surface of the billet, plays a crucial role in determining the surface quality. Higher cutting speeds can lead to increased heat generation, which can cause thermal damage to the surface and result in poor quality. Therefore, finding the optimal cutting speed is essential for achieving a high-quality machined surface. 2. Feed Rate: The feed rate refers to the rate at which the tool advances into the material during the machining process. A high feed rate can lead to excessive tool wear, resulting in poor surface quality. On the other hand, a low feed rate may cause chatter or vibration, causing surface irregularities. It is crucial to find the right balance to ensure a smooth and high-quality machined surface. 3. Tool Geometry: The geometry of the cutting tool, including its shape, angle, and edge sharpness, plays a significant role in determining the surface quality. The tool geometry affects the chip formation and the interaction between the tool and the billet. Proper tool geometry can minimize cutting forces, reduce vibration, and improve chip evacuation, resulting in a better surface finish. 4. Cutting Fluid: The choice and application of cutting fluids can greatly influence the surface quality of machined steel billets. Cutting fluids serve multiple purposes, including cooling the tool and workpiece, lubricating the cutting process, and flushing away chips. Appropriate cutting fluid selection and application can help in reducing friction, heat generation, and tool wear, leading to improved surface quality. 5. Billet Material and Hardness: The material composition and hardness of the steel billet also impact the machined surface quality. Different steels have varying levels of machinability, with some being more prone to issues like work hardening or built-up edge formation. Harder materials generally require more robust cutting tools and specific machining techniques to achieve desired surface quality. 6. Machine Rigidity and Stability: The rigidity and stability of the machine used for machining the steel billets are critical factors affecting the surface quality. Any machine tool deflection or vibration can lead to poor surface finish and dimensional accuracy. Therefore, it is essential to ensure proper machine setup, alignment, and maintenance to minimize unwanted vibrations and maximize surface quality. Overall, a combination of the above factors, along with proper cutting parameters and machining techniques, is necessary to achieve a high-quality machined surface on steel billets. Adjusting these factors based on the specific characteristics of the billet and desired surface finish can help optimize the machining process and improve the overall quality of the final product.

- Q:What are the different surface treatments for improved surface cleanliness in steel billets?

- There are several surface treatments available for improving surface cleanliness in steel billets, including shot blasting, pickling, acid cleaning, and electrochemical cleaning. Shot blasting involves propelling abrasive particles onto the surface to remove scale, rust, and contaminants. Pickling involves immersing the billets in an acid solution to dissolve oxides and surface impurities. Acid cleaning uses chemical solutions to remove surface contaminants and oxides. Electrochemical cleaning utilizes an electric current to remove oxides and impurities from the surface. These treatments help ensure better surface cleanliness and prepare the steel billets for further processing or applications.

- Q:What is the role of steel billets in the manufacturing of structural steel buildings?

- Steel billets play a crucial role in the manufacturing of structural steel buildings. These billets, which are semi-finished forms of steel, serve as the primary raw material for the production of various steel products used in construction. Firstly, steel billets are used to produce long steel products such as beams, columns, and rods. These components form the skeletal structure of buildings, providing support and stability. By shaping and processing the steel billets through processes like rolling, forging, or extrusion, manufacturers can create these essential structural elements. The high strength and durability of steel make it an ideal material for constructing buildings that can withstand heavy loads and adverse environmental conditions. Furthermore, steel billets are also used to manufacture other crucial components like plates and sheets, which are used for flooring, roofing, and cladding in structural steel buildings. These flat steel products provide a protective and aesthetically pleasing finish to the building, while also contributing to its overall strength and stability. The consistent quality and uniformity of steel billets ensure that the resulting structural steel components have the required mechanical properties, such as tensile strength and ductility, to meet the safety and performance standards demanded by construction projects. Steel billets are often produced using advanced manufacturing techniques, such as continuous casting, which further enhances the quality and reliability of the final steel products. In summary, steel billets are essential in the manufacturing of structural steel buildings as they serve as the raw material for producing various components like beams, columns, plates, and sheets. These components form the framework and protective elements of the building, providing strength, stability, and durability. Through careful processing and quality control, steel billets enable the production of high-quality steel products that meet the stringent requirements of the construction industry.

- Q:How do steel billets contribute to the manufacturing of furniture?

- The manufacturing of furniture relies heavily on steel billets, which serve as the essential raw material needed to create strong and durable frames. These billets, produced through casting or hot rolling, are semi-finished steel products with a rectangular shape. After obtaining the steel billets, they can undergo various manufacturing techniques such as forging, extrusion, or machining to shape them into different furniture components. These components include frames for chairs, tables, beds, and other elements that require stability and strength. Using steel billets in furniture manufacturing offers several advantages. Firstly, steel is renowned for its exceptional strength and durability, making it an ideal material for furniture that can handle heavy loads and regular use. By utilizing steel billets, the furniture becomes robust and long-lasting, reducing the need for frequent replacements. In addition, steel billets provide design flexibility as they can be easily molded and shaped into different forms. This allows furniture manufacturers to create intricate and unique designs that meet customers' aesthetic preferences. Moreover, steel billets can be seamlessly welded, resulting in a more cohesive and visually appealing final product. Furthermore, steel is highly resistant to corrosion, which is crucial for furniture that may be exposed to moisture or environmental factors. By incorporating steel billets, the furniture remains free from corrosion, preserving its appearance and structural integrity over time. In conclusion, steel billets are indispensable in furniture manufacturing as they provide the necessary strength, durability, and flexibility to create sturdy frames and structural components. Their utilization enables furniture manufacturers to produce high-quality products that are long-lasting, visually appealing, and resistant to corrosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel billet for rebar steel material from china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 24983 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords