Spiral plate heat exchanger(Non-Detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The spiralplate heat exchanger is a high-efficient heat exchanging equipment used inalcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration,organic chemistry, metallurgical industry, suitable for convection heattransfer of liquidtoliquid,gas to gas, gas to liquid.

The spiralplate heat exchanger comprises detachable and nondetachable exchanger. The spiral plate heat exchanger is made of carbon steel and stainless steel.

The argument list of carbon steel spiral plate heat exchanger

公称换热面积m2 | 通道间距m2 | 计算换热面积m2 | 流速1m/sec时处理量m3/h | 接管公称直径dg | 型 号 | 质 量(kg) I6T型 II6T型 | |

40 | 10 | 40.9 | 20.9 | 80 | I6.II6T40-0.6/1200-10 | 1730 | 2772 |

14 | 42.3 | 39.3 | 100 | I6.II6T40-0.8/1200-14 | 1843 | 2835 | |

18 | 44.9 | 63.5 | 125 | I6.II6T40-1.0/1200-18 | 2069 | 3061 | |

50 | 10 | 50.2 | 35.3 | 100 | I6.II6T50-1.0/1000-10 | 2334 | 3070 |

14 | 53.2 | 49.4 | 125 | I6.II6T40-1.0/1200-14 | 2408 | 3400 | |

18 | 54.0 | 76.3 | 125 | I6.II6T40-1.2/1200-18 | 2430 | 3422 | |

60 | 10 | 60.8 | 20.9 | 80 | I6.II6T60-0.6/1400-10 | 2673 | 4231 |

14 | 60.7 | 39.3 | 100 | I6.II6T60-0.8/1400-14 | 2750 | 4308 | |

18 | 61.6 | 63.5 | 125 | I6.II6T60-1.0/1400-18 | 3097 | 4655 | |

80 | 10 | 81.4 | 28.1 | 100 | I6.II6T60-1.0/1400-10 | 3365 | 4923 |

14 | 80.6 | 39.3 | 100 | I6.II6T80-0.8/1600-14 | 3445 | 5796 | |

18 | 82.0 | 63.5 | 125 | I6.II6T80-1.0/1600-18 | 3682 | 6033 | |

100 | 10 | 101.4 | 28.1 | 100 | I6.II6T100-1.0/1600-10 | 4250 | 6601 |

14 | 101.8 | 49.4 | 125 | I6.II6T100-1.0/1600-14 | 4390 | 6741 | |

18 | 108.2 | 76.3 | 125 | I6.II6T100-1.2/1600-18 | 4460 | 6811 | |

120 | 14 | 121.5 | 42.5 | 125 | I6.II6T120-1.2/1700-14 | 5130 | 7718 |

18 | 120.0 | 59.4 | 125 | I6.II6T120-1.2/1800-18 | 5250 | 7960 | |

130 | 14 | 130.5 | 32.5 | 125 | I6.II6T130-1.2/1800-14 | 5570 | 8280 |

18 | 131.0 | 49.4 | 125 | I6.II6T130-1.2/1900-18 | 5700 | 9005 | |

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

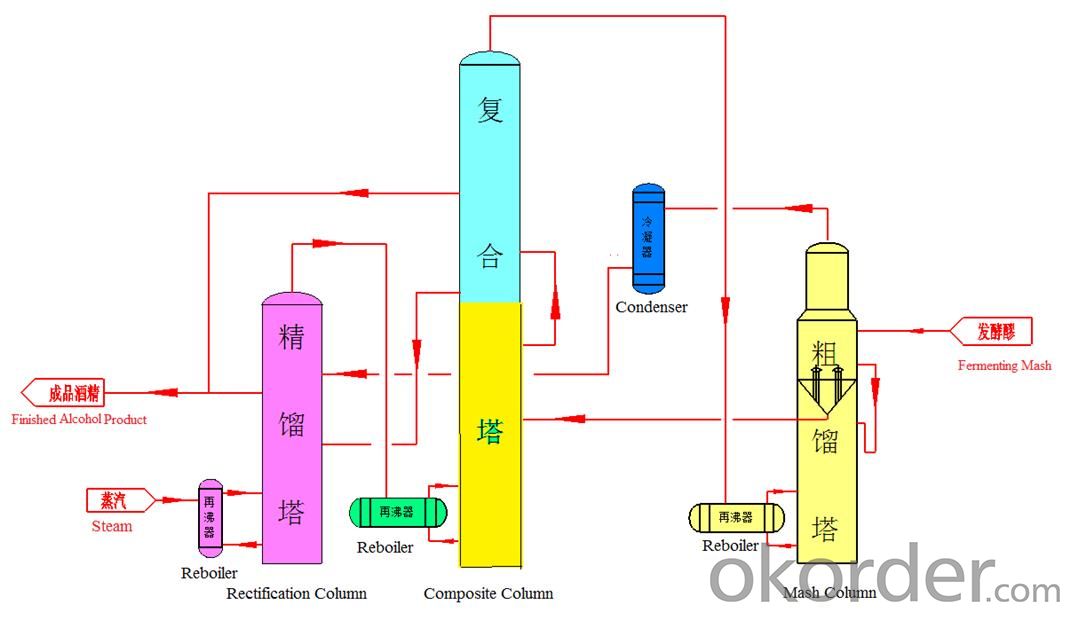

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety

Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q:The house I live in has fan-forced heating that consists of a fan blower and a gas heater. When the thermostat goes on, the fan and gas unit turns on. If the circut for the fan blower is cut off when the thermostat kicks on and the heat is supposed to be on, will the gas unit burn out because the fan isn't blowing?

- I'm not sure but I believe modern ones have thermal interlocks on the gas. I wouldn't trust that, though, particularly on older units.

- Q:For an outdoor pool, Is a swimming pool heat pump suitable in the uk for all year round swimming in terms of temperature and cost to run? I understand efficiency drops in colder weather.Thanks

- For an air to water heat pump, no, not really as a stand alone unit. Yes, if you add a gas fired heater as a back up for days that the outside air gets below 0C and you're sensible in keeping a solar blanket on the pool to minimize heat loss. As a general rule, when the air temp gets to -10 C, these units won't give you any heat at all or at least not enough to offset your pool's heat loss. If it's a geo thermal heat pump, your ability to scam heat gets better because you have a warmer source, but your costs also go up as their pretty expensive to buy and install. I've only ever seen this type in conjunction with household heating that has had the extra heat exchanger installed for the pool heat.

- Q:The AC unit is about 15 years old and is an all in one unit outside which has the gas is feeding into it. Just recently, when the flames ignite, we can hear a low rumble/banging noise coming from the unit. If this helps as to what it sounds like, my wife though I had shoes in the dryer. The sound is a bit more muffled than that though. I went outside and it sound like is air blowing over the flames kind of like you'd hear in one of those tubular portable propane heaters. A) Could this just be dirty nozzles? B) Would that possibly allow air to mix with the natural gas as it's burning and make that sound? The instant the gas goes off (with the blower still running) the noise stops. C) Is there any risk to continue running the system until someone comes out? It's only in the teens this week.Thank you

- DO NOT use it! It sounds as if your exchanger could be cracked letting carbon monoxide in the house. This WILL kill your family! Call a pro asap! 20 yrs exp - houston texas

- Q:Hello,I have a single story ranch with unfinished basement. I have central AC in my home. The air handler is located in the attic. There is existing hydronic baseboard throughout main floor, but it all needs replacing due to damage. Boiler in basement also is going to be replaced. My question is this:1) Should i replace hydronic baseboard with new, or should i take advantage of having central AC and run a hot water coil(heat exchanger) up to attic into air handler so i have central AC and heat?2) I am not familiar with whats involved with the air handler option. Can i use existing air handler to install hot water coil, or do i need to replace airhandler with one with a built in hot water coil?3) While I know hydronic baseboard is more efficient in heating vs a direct fired forced hot air furnace, what would be more efficient in this case since my senario is hydronic baseboard vs hydronic coil in central air handler? Again this is not going to be a direct fired furnace.Thanks.

- This Site Might Help You. RE: Hydronic baseboard heat VS hydronic water coil inside air handler? Hello, I have a single story ranch with unfinished basement. I have central AC in my home. The air handler is located in the attic. There is existing hydronic baseboard throughout main floor, but it all needs replacing due to damage. Boiler in basement also is going to be replaced. My question...

- Q:how it works

- For what purpose, using what source? Piping buried under ground, about 3 to 5 feet is a great way to improve the efficiency of a heat pump. This is considered to be geothermal heat. If you mean heat from a steam or hot water spring, such as we have here in northern California/Nevada, then the user either uses a heat exchanger at the source, or pipes the steam or hot water to the point of use. It gets messy due to the chemicals in the water or steam. That said, if you are running a power plant with it, and most of your income from it is profit, then the losses of equipment and waste disposal are out weighed by the money being earned.

- Q:From what I understand, vertical heatpipes have a quot;wickquot; inside which means that when the liquid boils at the base of the heatpipe and then condenses at the top of the heatpipe, it's wicked back to the base of the heatpipe.

- Yes it will work well. Usually wick type heat pipe used when condensation zone is below the evaporation zone. Wick use capillary action as its principle of movement, so heat pipes are often used in space application where, at zero gravity a wick has to be used. Where possible, under normal gravity, heat pipe heat exchangers (thermosyphon) should be operated with the condensation zone above the evaporation zone when the need for a wick can usually be avoided.

- Q:please help me answer this question.. very urgent needed... thanks a lot..

- Depending on water temperatures and materials of the shell, fouling may occur, on shell side. Delta T must be regulated to manufacturers specs. Also orientation and liquid venting may be an issue, I have seen this corrected with manifold type exchangers

- Q:I'm getting quotes for a replacement for our hot water heater. So far I've gotten 22K for materials and installation of a solar hot water heater (3-4 collector panels) with heat rejection and single zone open direct radiant heating to one floor (accessible through drop ceiling underneath). Both quotes include a backup hot water heating system; the expensive one would involve installing a new backup high efficiency heater by converting our propane tank to use for heating. This would be either the Polaris or 2 Takagi Jrs, one for the solar hot water and another to power the radiant heat. Another quote is for 12K for only the solar hot water and heat rejection using the Velux system.Are these really high? I've already contacted 3 companies but it doesn't look like too many people are installing them in Maryland yet. I'm still waiting on a quote from one final company. Thanks!

- Homemade okorder /

- Q:Ok i want to build a water heater system but i live in the northern US so i want to make a closed loop system for hot water i want to know how can i make a water heater with a heat exchanger inside the water heater can i just open up the tank cut the main tank open install a copper coil drill some holes for the coil in and out and seal the holes then weld the tank shut or would that not work?

- Most okorder /

- Q:We had a new AC put in around June and when we started up the furnace this small we're getting the smell kind of like something getting hot. We just had the furnace replaced this week (19 years old) and the smell is still there. Also, we had the ducts cleaned. We do have an unplugged booster fan in the ductwork from the previous owners. Any thoughts?

- whats a small ? its probably the duct fan plastic blade

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Spiral plate heat exchanger(Non-Detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords