Spiral plate heat exchanger(Non-Detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The spiralplate heat exchanger is a high-efficient heat exchanging equipment used inalcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration,organic chemistry, metallurgical industry, suitable for convection heattransfer of liquidtoliquid,gas to gas, gas to liquid.

The spiralplate heat exchanger comprises detachable and nondetachable exchanger. The spiral plate heat exchanger is made of carbon steel and stainless steel.

The argument list of carbon steel spiral plate heat exchanger

公称换热面积m2 | 通道间距m2 | 计算换热面积m2 | 流速1m/sec时处理量m3/h | 接管公称直径dg | 型 号 | 质 量(kg) I6T型 II6T型 | |

40 | 10 | 40.9 | 20.9 | 80 | I6.II6T40-0.6/1200-10 | 1730 | 2772 |

14 | 42.3 | 39.3 | 100 | I6.II6T40-0.8/1200-14 | 1843 | 2835 | |

18 | 44.9 | 63.5 | 125 | I6.II6T40-1.0/1200-18 | 2069 | 3061 | |

50 | 10 | 50.2 | 35.3 | 100 | I6.II6T50-1.0/1000-10 | 2334 | 3070 |

14 | 53.2 | 49.4 | 125 | I6.II6T40-1.0/1200-14 | 2408 | 3400 | |

18 | 54.0 | 76.3 | 125 | I6.II6T40-1.2/1200-18 | 2430 | 3422 | |

60 | 10 | 60.8 | 20.9 | 80 | I6.II6T60-0.6/1400-10 | 2673 | 4231 |

14 | 60.7 | 39.3 | 100 | I6.II6T60-0.8/1400-14 | 2750 | 4308 | |

18 | 61.6 | 63.5 | 125 | I6.II6T60-1.0/1400-18 | 3097 | 4655 | |

80 | 10 | 81.4 | 28.1 | 100 | I6.II6T60-1.0/1400-10 | 3365 | 4923 |

14 | 80.6 | 39.3 | 100 | I6.II6T80-0.8/1600-14 | 3445 | 5796 | |

18 | 82.0 | 63.5 | 125 | I6.II6T80-1.0/1600-18 | 3682 | 6033 | |

100 | 10 | 101.4 | 28.1 | 100 | I6.II6T100-1.0/1600-10 | 4250 | 6601 |

14 | 101.8 | 49.4 | 125 | I6.II6T100-1.0/1600-14 | 4390 | 6741 | |

18 | 108.2 | 76.3 | 125 | I6.II6T100-1.2/1600-18 | 4460 | 6811 | |

120 | 14 | 121.5 | 42.5 | 125 | I6.II6T120-1.2/1700-14 | 5130 | 7718 |

18 | 120.0 | 59.4 | 125 | I6.II6T120-1.2/1800-18 | 5250 | 7960 | |

130 | 14 | 130.5 | 32.5 | 125 | I6.II6T130-1.2/1800-14 | 5570 | 8280 |

18 | 131.0 | 49.4 | 125 | I6.II6T130-1.2/1900-18 | 5700 | 9005 | |

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

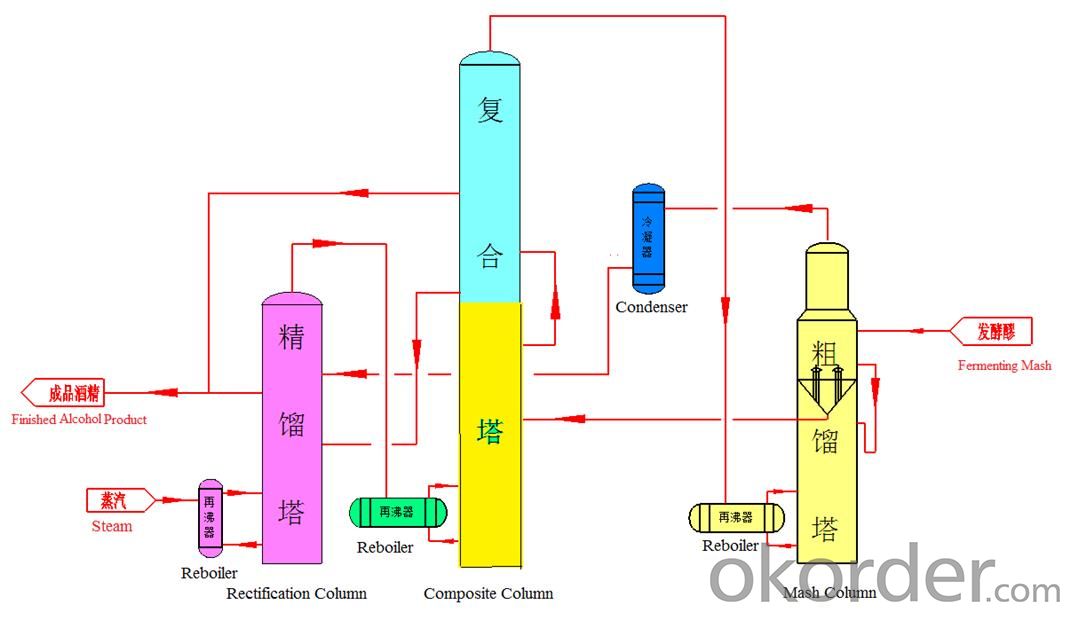

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety

Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q:An insulated heat exchanger is designed to cool an air flow from 640 K to 400 K both states at 500 kPa. The coolant is water taken from a stream at an average temperature of 15 degrees C and pressure 100kPa. If the water exits the heat exchange as saturated mixture with quality of .95, determine the mass flow rate of the water, in kg/s, necessary to attain the design parameters if the volume flow rate of the air is 12 m^3/s. (assume variable specific heats for air and R is .287 kPa-m^3/(kg-K)

- OK, okorder . It's free !

- Q:preferably a liquid to liquid heat exchanger. hopefully something with variables like flowrates, specific heat capacities, and inlet temperatures for each liquid, and surface area. a like to a website would be fine.

- Heat okorder /

- Q:I need to heat about 3500 gallons of biodeisel from 20°C to 45°C, i was thinking in using a Fired Heater and a Heat Exchanger, this is only for femonstrational purposes, but can anyone tell me an alternative mean to heat Biodiesel, less complicated and for god sake cheaper!!

- A fired heater will probably be the cheapest way. You could try electric heaters (you can buy the elements from water heaters at appliance repair shops - they use 240V), but the electricity cost will probably be more than for the fuel (if you were thinking gas/petrol, maybe propane or natural gas will be cheaper). I also don't know if I'd be comfortable putting electric elements in 3500 gallons of biodiesel - I've seen a few kitchen fires, and burning oil is never pleasant. You could also consider solar heating - it would be cheaper in the long run, but any efficient installation would have to involve heating panels, piping, pumps, and a lot of water. You could try painting your tank black, but that probably won't work very well unless you live in the desert or high plains.

- Q:under heat exchanger design .thanks

- The question is not clear. What heat integration scheme. More details would help. Your additional details just asks the original question over with no more info so I'll take a stab at your question. In using steam as a heat medium you want the lowest temperature that will satisfy your requirements. That typically is the lowest cost for the energy involved. Since steam temperature goes up with pressure you would then want the lowest pressure steam to achieve the temperature level you need for the heat exchanger design. Typically an approach temperature of about 5 degrees F is the economic limit for a given exchanger but you can by doing cost estimates determine if that is true for the case you might be studying.

- Q:I found out the area. Is it L=pi*D*L or L= n*pi*D*L and what is n?I have to find this for a) for one shell pass, 2 tube passes(b) for one shell pass, 3 tube passes(c) for two shell passes, four tube passes

- Starting from scratch you need the overall heat transfer coefficient and the approximate velocity that was used for that calculation. You also need the amount of heat to be transferred and the log mean temperature difference for the two streams. This is all basic heat transfer and heat exchanger design information With that information you can calculate a surface area. You have to select a tube size to determine the area per foot of tube length. From that you can get the total length of tubing you need. Next select the number of tubes so the velocity in the tubes will be in the range of that used to determine the overall heat transfer coefficient. With the number of tubes and the total tube length you can come up with the tube length needed to satisfy these conditions. Hint, the approach on the heat exchanger is typically 5 to 10 degrees F and a very common tube size is 3/4. Tubes typically come in increments of 10 feet up to about 60 to 100 feet. If you have multiple pass exchangers, you figure the tube length for a single pass and divide the length by the number of passes.

- Q:two apartment house -one oil fired hot water peerless boiler. When heating hot water circulating pumps do not run for heat. Is this correct? We took hot water off priority but still heats first before heat. Also we have run out of hot water (4 girls using) and it takes forever for turnaround time to heat water. In the meantime temperature in house gets colder as heat does not kick in until tank is full of hot water. Any suggestions?

- I am so very sorry, I cannot get past the part with 4 girls taking showers! My imagianations runs wild. I am not trying to be annoying but I bought a tankless water heater that never runs out of hot water and I love it so far! I know this would be a loot of work for you guys so ... I have a peerless for my small house heat ... the pump runs as soon as I need heat so I guess yours should too, no pumping means no water getting to your radiators... I would seperate house heat from shower heat and get a tankless, it's cheaper and ... never run out of hot water ... I am not the greatest persont o ask though since I am an electrician ... good luck and thanks for the shower images!

- Q:Once at the beginning of each season, I have to remove the cover of the heat exchanger in order for it to fire up. It seems to have something to do with too much vacumn in the chamber. After it fires up the first time, it's good for the rest of the season.

- Have it serviced.

- Q:I have two fluids entering a shell and tube heat exchanger.One enters at 393K and leaves at 323KThe other fluid enters at 353K and leaves at 308K.Is this even possible?

- It is not clear if these are measured numbers or calculated numbers. In the case of measured numbers I have seen such things happen due to errors in temperature measurement. In the case of calculated numbers I can only see a case where a fluid can enter an exchanger at a given temperature and leave at the same temperature while the other fluids is cooled down. That is the case of liquid such as a refrigerant liquid that enters the exchanger at its boiling temperature, boils and then leaves the exchanger at the boiling temperature.

- Q:what is the cheapest way to heat an inground pool?

- Having a pool cover and many sunny days.

- Q:which cooling fluid is available for this processc?

- As long as pressures are low, flat plate heat exchangers are cheapest to construct. If pressures are above 1 atm by much plate and tube is the next cheapest. Cooling fluids are either R-12 or its replacement (R-134a?) and ammonia (if food is involved) . Ammonia probably is cheapest and best refrigerant for industrial use. Other refrigerants at this temp are CO2 and propane

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Spiral plate heat exchanger(Non-Detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords