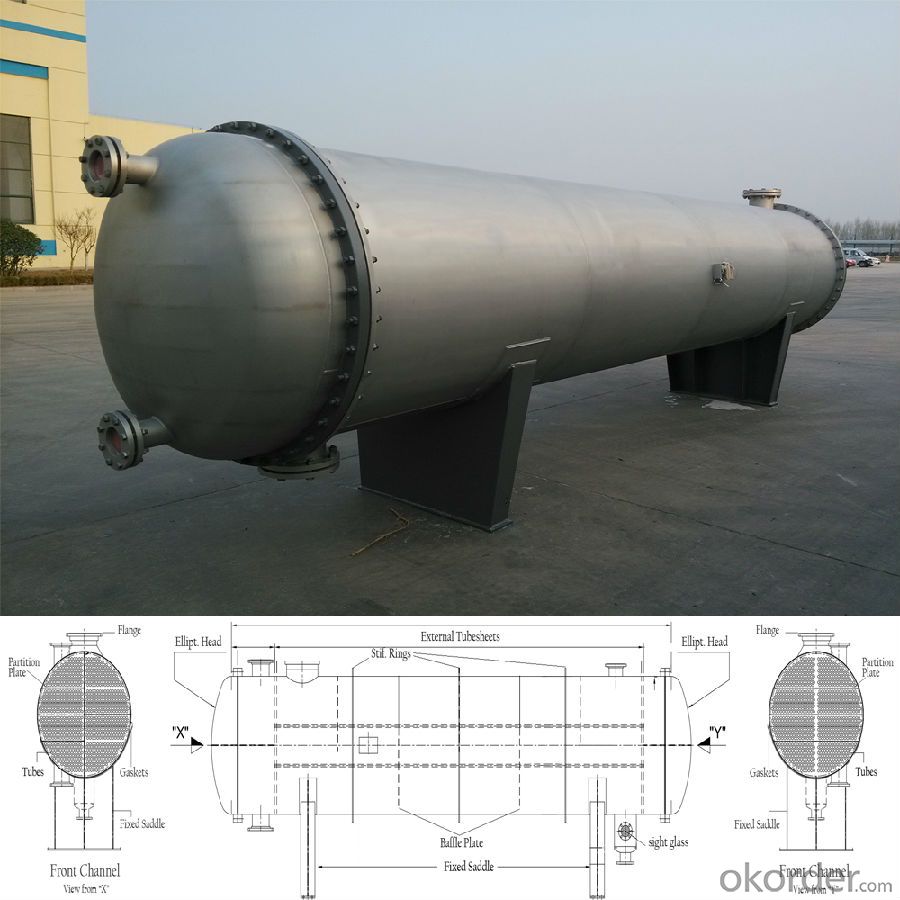

pre-heater

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-heater is a high-efficient heat exchanging equipment used in alcohol, solvent, foodferment, pharmaceutical, petrochemical, refrigeration, organic chemistry, metallurgicalindustry, suitable for convection heat transfer of liquidtoliquid,gas to gas,gas to liquid.

The heatexchangeris divided into tubular heat exchanger, spiral plate heat exchanger.And the tubular heat exchanger comprises condenser, Pre-heater, Re-boiler,Evaporator, drying machine. The spiral plate heat exchanger comprisesnon-dismountable and dismountable exchanger.

The heatexchanger is made of carbon steel and stainless steel.

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latest Five-Column Three-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

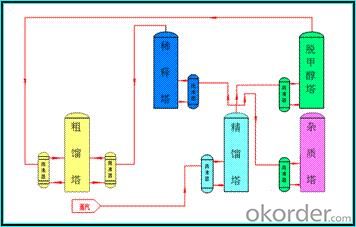

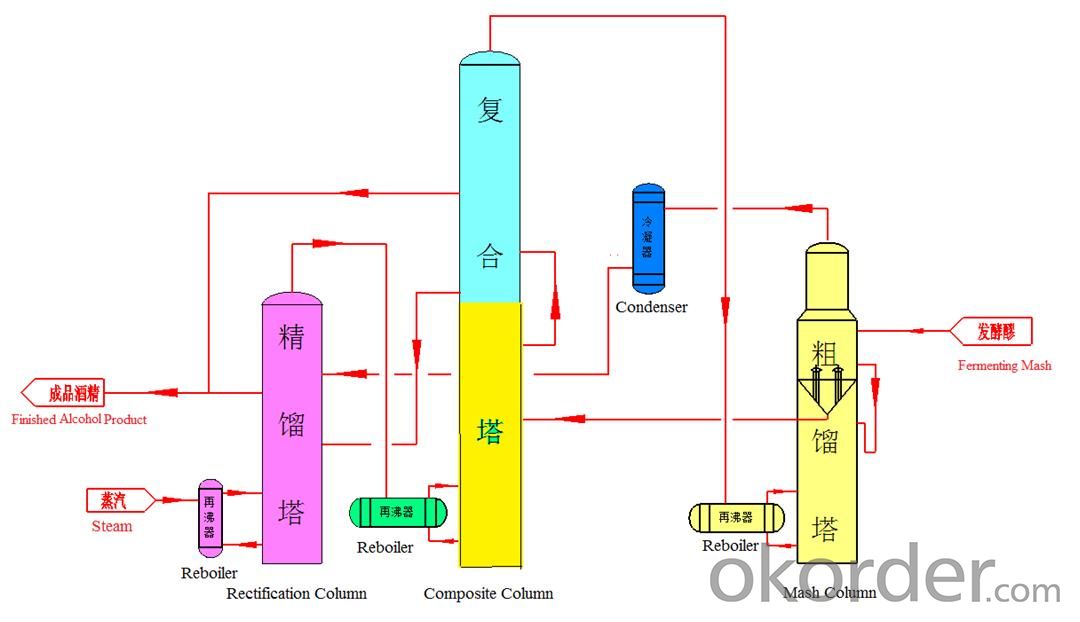

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;it saves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce 6 full sets of equipment (including crushing section, liquefying saccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2).We can reach the project site after receiving the user’s notification.

6.Package & Transport

- Q:What is a regenerative heat exchanger?

- Regenerative heat exchangers for regenerative heat transfer equipment.

- Q:I have heard that there is a minimum temperature at which you should have your house in the winter to protect the heat exchanger on a high-efficiency furnace. I've heard stories of people going on vacation and leaving their thermostat temperature set to 45 degrees or something, and it does damage to the heat exchanger. Is this true, and if so, what is the recommended minimum temperature that I should set my thermostat to ?

- I have installed and serviced many 90+ furnaces. It clearly states in the installation book you must have a min return air temperature of no less than 60 degrees for continuous running and 55 degrees for intermittent. Also you don't want the return air to be over 80 degrees. If the return air is too cold in a 90+ furnace the combustion air will condensate where its not suppose to, namely the unprotected first heat exchanger, and not just in the second, lined, heat exchanger. Which rots out the first heat exchanger. I would not set my stat lower than 60 just to be safe.

- Q:Hej! I would like to have a general idea of the cost...internal circular exchanger cost would be perfect, any other good as well... thx!

- A lot depends on the temp. diff. you're working with. Is there any vapor transfer to consider? A unit that big should be engineered for the application.

- Q:at temperature 120 C

- oeman50 is right on, but I would strongly suggest that you investigate whether your mixture is in the explosive range before having anything to do with this project !!! You need to consider possible process upsets, including startup and shutdown conditions as well. Even if this is in the explosive range, there are ways of doing it safely, but they are complex, and if only to cover your butt [legal liability] you should hire an expert.

- Q:Can i convert a tower fan into a cooler..by using a heat exchanger?

- What kind of heat exchanger? Moving air does not cool anything, it just moves air around. To get cooling you need either an condenser/evaporator such as in an air conditioner, or an evaporative cooling system, such as is used in swamp coolers.

- Q:After my heating system is shut off, (let's say after 10 PM), my fan is still running for a while (about 15 - 20 minutes). Meanwhile, it makes some noise. 1. Why is my fan is still running for quite a while after the heating system is shut off? 2. Why it makes noise? 3. How to fix it?

- This is a poke. Gas furnaces have fan limiters which determine how long fans run during the heat cycle. They're adjustable I know, but I can't help you much in telling you where the limiter is. Why is the fan making noise? It might just need some ordinary cleaning and light oiling.

- Q:I have a 15 year old Comfortmaker furnace. The heat exchanger was replaced in 2003 for free except for the labor to install.Now the heat exchanger is bad (cracked, ring left off). The tech who installed in 2003 is not longer available but I have his receipt with the model and serial numbers as followsModel: GDI078A012AINSerial: L934690028Is it worth replacing the heat exchanger for a 3rd time in a furnace this old or time to replace with more efficiency? Also what would make the heat exchanger keep going bad (cracking, etc.) could it be getting too much pressure /heat? or a duckwork problem. Please help. Thanks.

- If you have the means, replace the furnace because cracked heat exchangers = carbon monoxide. Since this is number three, going for four is kinda like playing Russian Roulette. :( Poor return and supply duct capacity might be the cause of failure. As well as improper fan speed (too slow) or dirty filters. An improperly adjusted gas valve or a botched fuel conversion could be a cause as well as faulty burner controls. Have these points checked/evaluated when you request bids for a new furnace. Any reputable HVAC outfit should be eager to answer your questions if they truly value your business.

- Q:When central heat unit kicks on it starts blowing right away. Which is cold air and then the hot air comes on after a little bit

- That is a natural characteristic of electric heat..... the reality is that the duct work holds that cool air in suspension, then when the blower fan starts, the heat strips must get hot (which only takes slightly less than 15 seconds) for that air to become warm. if this is gas heat then you need a tech out there first thing tomorrow. The inducer fan for some reason is either not running or the fan switch really needs to be re calibrated, or is failing on temp delay. On gas furnaces the heat exchanger must get hot before the blower fan is supposed to energize... (edit) Since the duct work is the same in both electric and gas systems, it stands to reason that same cool air has to be displaced by warm air. Instead of thinking YOU are an idiot or calling another poster an idiot, I figured you were smart enough to extrapolate that...... The reality is that gas systems will displace that cool air much better; the air from an electric furnace is only 87 to 92F, the gas furnace will produce 130 degree air all day long. An idiot wouldn't know that. Its a shame mg couldn't point that out.... It must be a real joy working with mg..... not

- Q:Prove that hot can never be colder than cold?

- In your example heat transfer is proportional to minus the temperature gradient, so heat never flows into hot. To prove it?... Isn't it the second law in some statements? Wiki says, the simplest formulation of the second law, the heat formulation or Clausius statement: Heat generally cannot spontaneously flow from a material at lower temperature to a material at higher temperature. EDIT: Classical Thermodynamics assumes relatively slow processes, so that a system changes state smoothly.

- Q:i'm doing this experiment on heat exchanger. I'm supposed to discuss the effect of changing the flow rate on the overall heat transfer coefficient as well as the effect on the temperature and efficiency. I need some help so anything would be great.

- Heat Exchanger Flow Rate

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

pre-heater

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords