The spiral plate heat exchanger (Non-detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The spiralplate heat exchanger is a high-efficient heat exchanging equipment used inalcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration,organic chemistry, metallurgical industry, suitable for convection heattransfer of liquidtoliquid,gas to gas, gas to liquid.

The spiralplate heat exchanger comprises detachable and nondetachable exchanger. Thespiral plate heat exchanger is made of carbon steel and stainless steel.

The argument list of carbon steel spiral plate heat exchanger

Nominal heat transfer areaNominal heat transfer areaNominal heat transfer area | Channel Spacing | Calculate heat transfer area | handling capacity(flow rate: 1m/sec) | Nozzle nominal diameter | Model | I6T quality II6T quality | |

40 | 10 | 40.9 | 20.9 | 80 | I6.II6T40-0.6/1200-10 | 1730 | 2772 |

14 | 42.3 | 39.3 | 100 | I6.II6T40-0.8/1200-14 | 1843 | 2835 | |

18 | 44.9 | 63.5 | 125 | I6.II6T40-1.0/1200-18 | 2069 | 3061 | |

50 | 10 | 50.2 | 35.3 | 100 | I6.II6T50-1.0/1000-10 | 2334 | 3070 |

14 | 53.2 | 49.4 | 125 | I6.II6T40-1.0/1200-14 | 2408 | 3400 | |

18 | 54.0 | 76.3 | 125 | I6.II6T40-1.2/1200-18 | 2430 | 3422 | |

60 | 10 | 60.8 | 20.9 | 80 | I6.II6T60-0.6/1400-10 | 2673 | 4231 |

14 | 60.7 | 39.3 | 100 | I6.II6T60-0.8/1400-14 | 2750 | 4308 | |

18 | 61.6 | 63.5 | 125 | I6.II6T60-1.0/1400-18 | 3097 | 4655 | |

80 | 10 | 81.4 | 28.1 | 100 | I6.II6T60-1.0/1400-10 | 3365 | 4923 |

14 | 80.6 | 39.3 | 100 | I6.II6T80-0.8/1600-14 | 3445 | 5796 | |

18 | 82.0 | 63.5 | 125 | I6.II6T80-1.0/1600-18 | 3682 | 6033 | |

100 | 10 | 101.4 | 28.1 | 100 | I6.II6T100-1.0/1600-10 | 4250 | 6601 |

14 | 101.8 | 49.4 | 125 | I6.II6T100-1.0/1600-14 | 4390 | 6741 | |

18 | 108.2 | 76.3 | 125 | I6.II6T100-1.2/1600-18 | 4460 | 6811 | |

120 | 14 | 121.5 | 42.5 | 125 | I6.II6T120-1.2/1700-14 | 5130 | 7718 |

18 | 120.0 | 59.4 | 125 | I6.II6T120-1.2/1800-18 | 5250 | 7960 | |

130 | 14 | 130.5 | 32.5 | 125 | I6.II6T130-1.2/1800-14 | 5570 | 8280 |

18 | 131.0 | 49.4 | 125 | I6.II6T130-1.2/1900-18 | 5700 | 9005 | |

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

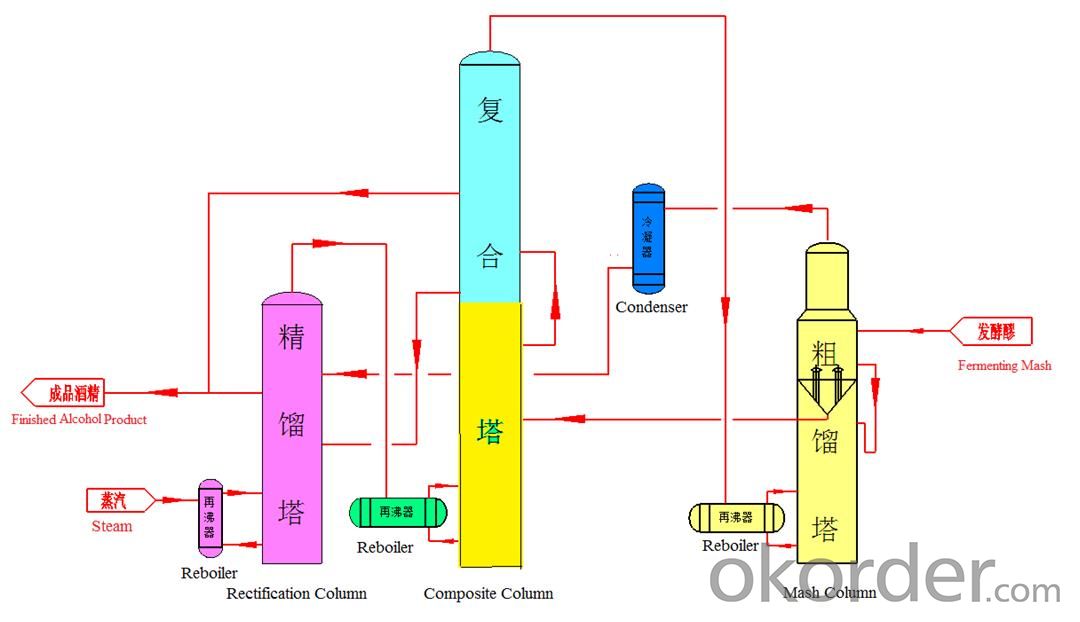

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q:i have a 1999 pontiac grand prix se and my heat is not working at all.even if you turn the knob it won't turn on.my mechanic says that there is an electric problem.that it's not getting any power.is it possible to directly connect the heater to the battery without any risks.i already checked all the fuses and they're fine.

- WHO IS GOING TO USE A HEATER WHEN HE HOT?

- Q:note that the flow is assumed to be turbulent

- Questions look bad without answers.

- Q:I have been told quadrafires aren't as good as St. Croix or Enviro.Somebody wrote that the stoves are now made in China....is that true?They have an aluminum heat exchanger which I believe the Harmins and others have stainless steal.I could save about $500 by going with a quadrafire, but obviously I don't want to if they are going to be junk...help!!

- Quadrafires and Harmans are popular brands here if that makes any difference. I don't use a pellet stove but it's my understanding they don't really get that hot so would the difference between aluminum and stainless really matter? Perhaps the thickness of the metal would be the determining factor. I've heard more discussion on the type of auger, fans, and motors than heat exchanger. (I use a wood stove which is less complex and gets really hot).

- Q:Price of heat exchanger for a furnace?

- If the heat exchanger is under warranty I suggest you buy a new heat exchanger. Some of these have a warranty of 2 years to a lifetime warranty. if it is not under warranty, I suggest you gather some quotes for a new furnace even though it will still cost you more to replace the whole furnace. The supply house COST of one can vary. $0 (warranty) - $3,000. (usually around $500 for residential)

- Q:Is it possible to use an air conditioner to heat a pool? It seems like I might be able to use a liquid heat exchanger to cool the hot part of the air conditioning cycle using swimming pool water. Can someone give me an overview of how to build a system like the following myself

- I have never seen an actual AC heat a pool but by theory it would work. It probably wouldn't raise the temp of the pool enough to notice but it should make your AC more efficient. I wired up a system 6 months ago that had the same components as an AC (compressor, metering device, coils) that heated some doctors pool. It pulled 100A though. I don't know if it would be more efficient than gas. Email me at and remind me to call him to see if it worked well, if it was efficient, and what name brand. I have also installed water heaters that are pre-heated by a heat pump. The superheated vapor circulated through the water heater before returning to the condenser. Hope this helps!!!

- Q:Please tell me the name of heat exchanger specific .

- Air to liquid heat exchanger

- Q:The hot water is working, I just want to know what else to check, if there is a valve that needs to be turned or if my temp isn't set correctly.

- Hello Tammy. Your question has been unanswered for 2 days. My best guess is because it needs a few more details. Is your installation a boiler, feeding a heat exchanger to forced air? How long since you witnessed it functioning? Has it been worked on?

- Q:We have a Worcester 24i junior boiler for our gas heating/water.A few weeks ago the entire town lost water pressure for a day. Since then the boiler only heats the water if the central heating is on.Now it's stopped heating water ever when the central heating is on. The pressure is 1.5 bar, the radiators have all been bled recently, we've read a mission questions like this but with no solution.The quot;reset buttonquot; is, according to the manufacturer, on the top of the boiler at the left, there's nothing there!I do not have boiler cover.

- Were you informed that the water was going to be shut off.You may have damaged the heat exchanger. As it is there are a number of fault areas to look at .Thermister,bypass,solenoid/diverter,etc... You will have to get a professional to have a look.I know british gas do a one price fix ,i dont know the detail but this should be a fairly simple fix. Mick

- Q:i need that information to find the heat transfer coefficient. Thanks in advance

- The hot fluids could be steam, heat medium fluids, natural gas or propane associated with compression, any of the paraffin series of hydrocarbons, ethylene or triethylene glycol, amines, steam condensate and sulfur. The cold fluids could be any of the paraffin series of hydrocarbons, glycol, natural gas

- Q:but when using shell and tube we use mean temperature

- Actually you use log mean temperature difference for all counter current heat exchangers. It gives a more representative case for the difference between the two fluids as they pass through the heat exchanger. Double pipe is just a specialized version of a shell and tube exchanger and the heat transfer calculation is treated the same

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

The spiral plate heat exchanger (Non-detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords