SMD LED

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

SMD LAMP can be used in many aspects,like:

Lighting used in Automobile;

Indoor&Outdoor display; Traffic Indicating;

Scrolling Display or Panel;

And general Lighting and so on.

Products in photo album are part of main products in my company.And we also can

manufacture other smd led according to the requirements from customers.

Looking forward to your inquiry!

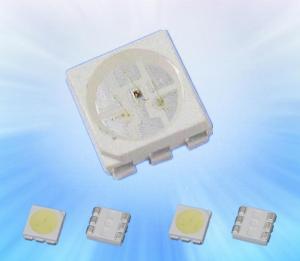

- Q:What does "1210" mean in patch LED?

- 1210 refers to the lamp specifications.LED common lamp specifications and parameters of patch0603, 0805, 1210, 3528, 5050 refers to the LED lamp belt, often used in light-emitting components ----LED size (English / Metric) name, for example, 0603 refers to the length of 0.06 inches, width of 0.03 inches. But note that the 3528 and 5050 units are metric

- Q:The ten patch LED lights are connected in parallel. The rated power is 5 watts. How much voltage do you need?

- The voltage needs to be determined according to the product specification, usually 3.1 - 3.5V

- Q:Which is good for LED patch and LED bulb?

- LED (light emitting diode) patch (package)LED patch (SMD) made by FPC circuit board, LED, high quality silica gel. The waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising - Entertainment decorative lighting lighting field.LED bulbA solid state semiconductor device that converts electric energy into visible light by means of LED (light-emitting diode), which converts electricity directly into light; LED = Large, Electronic, Display,;

- Q:Indoor full color LED display module and LED what is the difference between a full color?

- (1): LED full color light emitting module display module is generally yellow green, pure green module price is more expensive; SMD full color LED display using pure green tube coreThe display module (2): LED full color pixel visual feeling is thick, low brightness, easy to have the mosaic phenomenon; patch LED full color consistent, high brightness;(3): maintenance module LED full color display is not easy to maintain, the whole module replacement cost is high; SMD full-color LED screen for easy maintenance, repair and replacement of single lamp;

- Q:How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

- You can also use the ohmmeter's ohmmeter. To dial multimeter, to "ohm X1" file, the light emitting diode when the red pen is connected to the positive terminal of SMD LED, the black probe is connected to the negative terminal of SMD LED.

- Q:Does anyone know what the current rating of a white high brightness LED patch is? Where can I find out?

- LED high power and low power, small white rated current and LED wafer, such as a chip is 20MA two 40MA.... High power 0.5W, 100-150MA, 1W, 350MA current rating in the relevant product specifications

- Q:How do led patches measure good or bad?

- LED patch how to measure methods: use two meter meter test, red pen is positive, black pen negative, if there is "bee" sound is bad, if the light is good

- Q:What is patch SMD-LED?

- SMD LED is the surface mount light emitting diode. It is a solid state semiconductor device that converts electricity directly into light. The heart of LED is a semiconductor wafer, one end of which is attached to a bracket, one end is negative, and the other is connected to the positive electrode of the power to encapsulate the entire wafer with epoxy resin.

- Q:What are the storage requirements of SMT patch LED (LED)?

- Moisture-proof packing- anti SMD LED in the transport and storage of moisture absorption, SMD LED shall be placed in sealed moisture-proof bag, inside put damp proof agent for protection, and placed the humidity humidity SMD display card packaging bag.

- Q:Patch LED features

- The principle of luminescence is that of cold luminescence, not by heating or discharging light, so the component life is about 50~100 times longer than that of tungsten filament bulb, and about one hundred thousand hours.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SMD LED

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords