Self priming 6 inch diesel water pump with trailer

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction

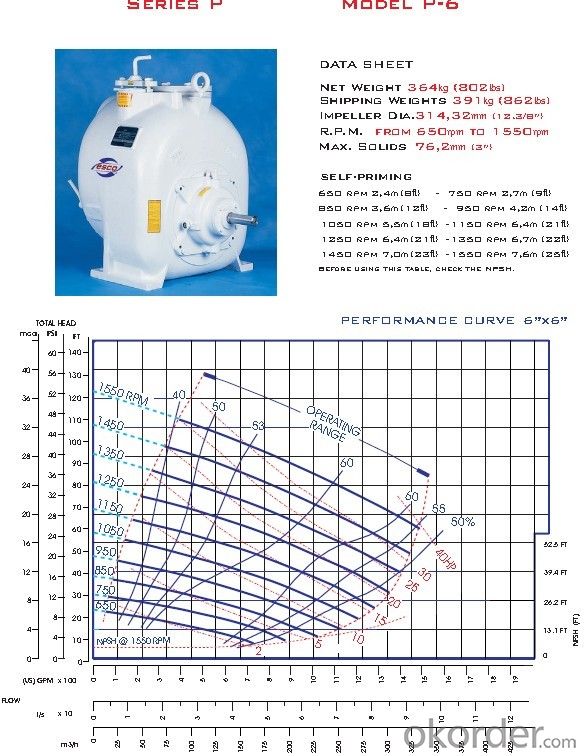

Main datas:

Capacity( flow rate) :35 ~ 310m3/h

Head :5~58 m

Speed:850 ~ 1950rpm

Impeller diameter:317.5mm

Pump weight:413kg /437kg

Power:5 ~ 75 hp

Advantage :

Big pump body pass 31.75mm solid ,high suction head 7.6 m

Convenient repair and clean (a person ten minutes)

Removable cover plate ,replaceable wear plate

OEM ,L/C ,TT ,O/A ,D/P,D/A and so on

CE ,TUV .ISO

NAME: 6 inch diesel water pump

Standard Self-Priming pump units are available for Solids Handling or Clear Liquid service. Typical mounting configurations are Engine Driven for Skid or Trailer Mounted packages and Frame Mounted Electric Driven. Pumps also are available in a variety of different metallurgies.

1) Main Character

1.Beautiful shape and fine structure,reliable performance.

2.With strong capacity of delf priming, no need to equip with flap valve.

3.Non-clog, and with powerful capacity of passing big solid..

4.The hole can make sure that stronger sewage can be cleaned quickly when pump is jammed.

5.The unique lubrication oil mechanical seal cavity makes the performance more reliable.

6.Special check valve structure can make the pump working quickly.

7. When working, the gas and liquid works together .

8. Low rotary speed,reliable operation,long time usage, easy to maintenance.

9.Advanced pressure protector make pump the pump work safe.

2) Application Area

1. Municipal project, sewage project, instruction project.

2.Uptown,hospital, hotel sewage transportation.

3.Classification of municipal sewage factory treatment and concentrate system engineering.

4. Factory and contaminated water delivery.

3) Industries Served

♦ Construction | ♦ Industrial | ♦ Municipal |

♦ Agricultural | ♦ Mining | ♦ Dewatering |

♦ Industrial Waste | ♦ Sewage | ♦ Oil Field |

♦ Petrochemical | ♦ Paper Mills | ♦ Processing |

4)Parameter

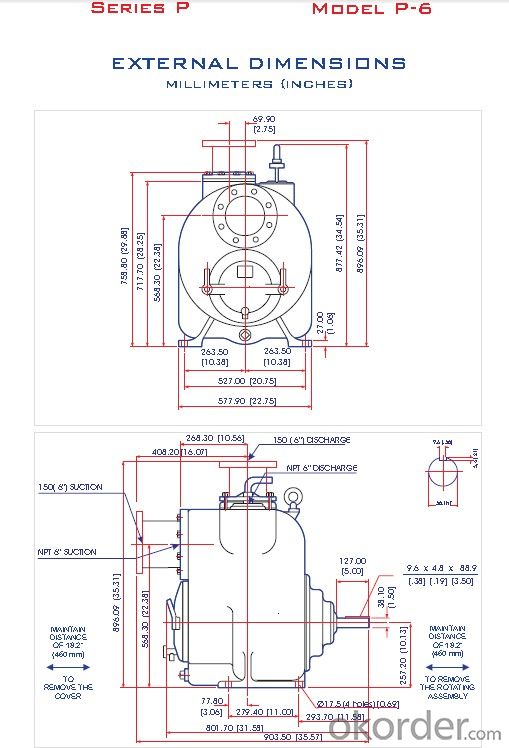

| 1.Inlet/Outlet | 2''(50mm), 3''(75mm), 4''(100mm), 6''(150mm), 8''(200mm), 10''(250mm), 12''(300mm) | |

| 2.Impeller Diameter | 158.74mm-457.2mm | |

| 3.Rotary Speed | 550RPM-2150 RPM | |

| 4.Flow Rates | 8m3/h-1275m3/h | 20GPM-5500GPM |

| 5.Head | 6m-63m | |

| 6.Horsepower | 1HP-125HP | |

| 7.N.W | 92KG-998KG | |

| 8.G.W | 114KG-1066KG | |

| 9.Solid Passing | 20.63mm-76.2mm | |

| 10.Material | Cast Iron, ADI, CD4MCU, 316 SS, Alloy 20, C276. | |

| 11.Diesel Driving | Water cooled or air cooled | |

| 12.Method of Connection | Self-priming pumps are available as basic units or may be flex-coupled, V-belt driven or engine mounted. | |

| 13.Drive Variation | Cummins, Deutz, Ricardo, Perkins or Chinese Diesel, Electric Motor | |

| 14.Skid Mounted on Trailer | 2 or 4 wheels Trailer/Trailor,Cart | |

| 15.Package | Exporting plywood case | |

| 16.Certification | CE , ISO9001:2008 ,TUV | |

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Prameter

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Samply available: 7~10days.

Qty: 1pc, only pump head is provided.

Price: US$100~200

OEM is welcome

OEM expierence: more than 10 years.

Countries: Germany, U.S.A, Spain, Italy, United Kingdom etc

Warranty: the whole pump is guaranteed within 1 year, the pump's spare parts are guranteed for 3 months from the date of delivery.

For more information, please do not hesitate to contact me.

The information should be including inquiry as following:

1.Pump's flow rate

2.Pump's Head (Pressure)

3.Driven Mode: By electric motor or diesel engine or bare shaft etc

4.Power and rotary speed

5.Suction lift for self priming pump

6.Temperature of liquid if you can provide

Upon the receipt of the pump's parameter, we can send our quotation to you within 24 hours.

Or the condition of pump station would be provided.

♦FAQ:

1. Q: Can I know more about your products?

A: Pls view our website: www.lanco.cc.

2. Q: What’s your MAQ of this item?

A: 1~2PCS

3. Q: What is the lead time?

A: 10~30 days after receiving your payment,depends on pumps.

4. Q: where is your loading port?

A: Ningbo, China port

5. Q: Are you a manufacturer or trading company

A: We are a manufacturer specialize in water pump and other pumps more than 20 years.

For more information, please contact me.

- Q:What is the nominal pressure of the hydraulic pump and hydraulic motor?

- Rated flow refers to the flow under the rated speed and rated pressure input to the motor.Due to leakage loss, the actual flow of the input motor must be greater than its theoretical flow. Actual flow of motor (i.e. inlet flow) leakage flow = theoretical flow of the motor.

- Q:How is the pump level of submersible sewage pump determined?

- Below the top elevation of the sump, 200 is the warning water levelBut note: 1, the effective volume of the sump meets the requirements. 2, the pump should have enough submerged water level

- Q:Working principle and diagram of axial piston pump with pressure compensation variable

- The size of the outlet flow pressure compensated variable displacement pump with outlet pressure of approximately in a certain range according to the constant power curve. When the pressure oil from the main part of the channel (a), (b), (c) into the inferior vena cava (d) variable shell, oil by the channel (E) respectively into the channel (f) and (H), when the spring force is greater than the oil (f) into the lower end of the piston ring servo hydraulic thrust area when the oil liquid (H) to the chamber (g), push the variable downward movement of the piston, the pump flow increases. As for the hydraulic servo piston end thrust force ring shaped area is greater than the spring when the servo piston moves upward, blocking channels (H), the (g) (I) through the cavity of the oil cavity pressure relief, at this time, the piston moves up, the variable head angle decreases, the pump flow rate decreases.

- Q:What is the difference between centrifugal pump and rotary vane pump? What are the distinctive characteristics or principles of rotary and centrifugal? O (a _ U) O thank you!

- Directly said vane pump on the line, generally do not say rotary vane pump.The centrifugal pump is divided according to the direction of the liquid flow in the impeller

- Q:What is the function of a submersible pump?Do you have any knowledge about submersible pumps?.

- The working principle of submersible pumpBefore the pump is opened, the suction pipe and pump must be filled with liquid. Open the pump, the impeller rotating speed, which leaves the liquid together with the rotation under the action of centrifugal force, the left outside impeller injection, injection of the liquid in the pump shell gradually slow the spread of indoor speed, the pressure gradually increased, and then from the pump outlet, the outflow discharge tube. At this time, in the leaves at the center of the vacuum area of low pressure liquid was thrown to the surrounding formation there is no air and no liquid, liquid pool at the surface of the liquid under the action of atmospheric pressure, through the suction pipe into the pump, the liquid is continuously pumped up from the liquid pool is also continuously from the outflow discharge tube.

- Q:What are the main performance parameters of hydraulic pumps?

- Main performance parameters of hydraulic pump:1. Hydraulic pump pressureHydraulic pump operating pressure is the pump (or motor) in actual work output (or input) oil pressure, determined by the external load.Rated pressure refers to the maximum pressure under continuous running in accordance with the test standards under normal working conditions. The size of the pump is limited by the service life, and the service life of the pump (or motor) will be shorter than the design life if it exceeds the rated pressure. When the work pressure is greater than the rated pressure, it is called overload.

- Q:Operating procedures for measuring pumps

- Pressurization(1) for the discharge pressure below 2.0MPa, then the pump stroke length should gradually increase, each increase of 20%, to maintain 15 minutes.(2) for the discharge pressure greater than 2.0MPa, you need a special pressure, to ensure that the pump discharge pressure gradually increased, each time for the final row pressure of 20%.(3) when the pressure is not increased, the stroke of the pump is gradually increased by 20% strokes per time.Note (1) when pressure is applied, the pressure gauge should be observed at the side of the loading side (slow motion)(2) check ammeter, forbid overload

- Q:Fire hydrant pump button, under what circumstances do not need to install?

- The installation of hydrant pump buttons depends on the type of water supply:(1) municipal water supply; (in this case, do not have to install)(2) there is a fire pump; (must be installed)

- Q:Water pump does not produce water, what are the reasons?

- The reason why centrifugal pump does not produce water:1. pump inlet or sink, water tank water shortage.2. water pump pipe blocked or valve not open.

- Q:What's the pump? Where can I use it?

- Pump can usually be divided into three types of displacement pumps, power pumps and other types of pumps according to the principle of operation. In addition to classification according to the working principle, it can be classified and named according to other methods.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Self priming 6 inch diesel water pump with trailer

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords