Scaffolding Spanner Rathcet Socket Wrench Hand Tools

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 50000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

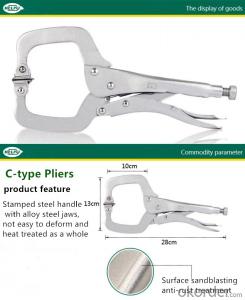

Scaffolding Spanner Rathcet Socket Wrench

Material:CR-V, 40cr

Finish: mirror polish ,sand blasting,matt,Black,spray

SIZE:

10*12

11*13

12*14

13*17

14*17

17*19

17*21

17*22

19*21

19*22

19*24

21*23

22*24

21*26

24*27

24*30

27*30

27*32

30*32

32*36

36*41

Packing:AS your request

- Q:What's a chain wrench?

- The chain is hinged with the clamp handle through the connecting plate, that is, one end of the chain is hinged with one end of the connecting plate, and the other end of the connecting plate is hinged with the clamp handle. The teeth at the front end of the clamp handle arc distributed in an arc. The chain type pipe at work, non articulated chain end is free, and the clamp handle is fixed or hinged, pipe clamping, rotating by friction between the pipe and winding its chain to achieve, and the torque by the meshing force of local cone and the front end of the clamp handle chain produced no, the clamp handle force on the pipe surface sites.

- Q:How to repair the air (pneumatic wrench)

- The air is used in the compressed air, compressed air enters the air cylinder to drive after the inside of the impeller and impeller rotating power, and then drive against parts connected by hammering similar movement, after each keystroke to screw up or down. It is an efficient and safe pneumatic wrench for dismounting screws.

- Q:What's the wrench for removing the cast iron radiator?

- Tool hammer, flat shovel is necessary etc..Ordinary cast iron radiators are divided into two kinds, one is called big 50, one is called "five small and zero", and their height is not the same, just 50 centimeters. As for disassembly and assembly, there are special tools (we call drum key here), it is recommended that you go to find a special plumber to help you assemble and disassemble, if you secretly get, not only you can not open, but also easy to leakage Oh ~ ~!

- Q:Screwdriver and "wrench" is the same tool?

- WrenchWrenchA manually operated tool for screwing bolts, screws, nuts, and other threads to secure the opening or sleeve of a bolt or nut. The wrench is usually provided with a clamping handle at one end or both ends of the handle part, and when an external force is applied to the handle, the bolt or nut can be screwed, and the opening or the hole of the bolt or nut can be screwed. When the utility model is used, an external force is applied to the handle in the direction of rotation of the screw thread, and the bolt or nut can be screwed.Wrenches are usually made of carbon structural steel or alloy structural steel.Several types of wrenches commonly used.Wrench: a fixed size opening at one or both ends is used to twist a nut or bolt of a certain size.Ring spanner: both ends have a working end with six corners or twelve corners. It is suitable for occasions where the working space is narrow and the ordinary spanner can not be used.Dual purpose wrench: one end is the same as a single head wrench, and the other end is the same as the plum wrench. The bolts or nuts with the same specifications are screwed at the two ends.Adjustable wrench: the opening width can be adjusted in a certain size range, and screws or nuts with different specifications can be screwed.Hook wrench: also known as the crescent wrench for screwing thickness restricted flat nut etc..Socket wrench: it is composed of a plurality of sockets with six corners or twelve corners and is provided with a handle, a connecting rod, etc., and is especially suitable for screwing bolts or nuts with very small or very concave positions.Inner six angle wrench: a L shaped six angle wrench, used exclusively for screwing six angle screws.Torque wrench: it shows the applied torque when screwing a bolt or nut; or when the applied torque reaches a specified value, it emits a light or audible signal. Torque wrenches are suitable for assembly work that specifies the torque magnitude.

- Q:What do you mean by the bolt capacity of the pneumatic wrench?

- This is the wrench. How big is it to tighten the bolts?

- Q:What's the manual wrench?

- Texture of material1.: chrome vanadium chemical symbol CR-V, is of good quality steel;2. carbon steel: quality in general, more circulation in the market.

- Q:Does the car show a small wrench? Is it the indication of maintenance? How to make it disappear?

- There is no indication of maintenance on the instrument panel. A wrench like condition indicates that the car is out of order and not in need of maintenance.There are many reasons for the trouble:Unreasonable operations will prompt;Mechanical failure in the form process;More because of random problems, in general, do not pay special attention to, if you care about, you can go to overhaul.

- Q:What material do open wrenches use?

- The open spanner is made of 45# medium carbon steel.

- Q:The difference between brush and brush in rechargeable electric wrench

- The difference between brushless electric wrench and brush electric wrench is a brushless electric wrench with digital control circuit commutation and speed reducer, electric wrench. Brushless electric wrench is no longer the use of mechanical brush commutation device solves the problem of life brush electric wrench insurmountable.

- Q:Will the wrench screw produce static electricity or sparks?

- Gas equipment construction, it is best to close the valve, exhaust gas, step-down. If the hot work should also be nitrogen replacement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Scaffolding Spanner Rathcet Socket Wrench Hand Tools

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 50000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords