Roller for Steel Rolling Mill Forged Mill Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Roller for Steel Rolling Mill Forged Mill Roll

Products Description

Centrifugally cast compound steel back -up rolls have a shell of cast steel with alloying elements such as Ni,Cr,Mo.After heat-treatment the roll shell get a fine temper structure, which exhibits good strength and ductility combined with high fatigue properties. When used, the roll shows a high wear and spalling resistance all the time.

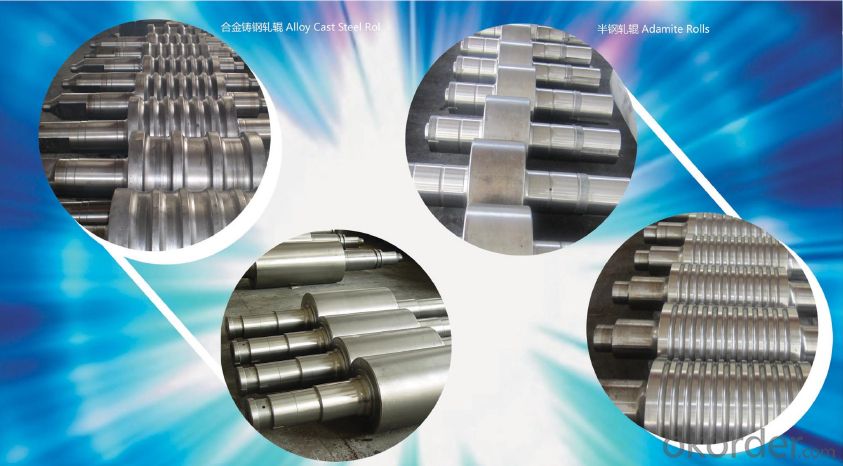

Products Pictures

Chemical Composition:

Classification | C | Si | Mn | P | S | Ni | Cr | Mo |

CrMo semi-chilled nodular cast iron rolls | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 0.20-0.60 | 0.20-0.60 | |

CrMo indefinite chilled nodular cast iron rolls | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 0.20-0.60 | 0.20-0.60 | |

NiCrMo indefinite chilled nodular castiron rolls(Ⅰ) | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 0.50-1.00 | 0.20-0.60 | 0.20-0.80 |

NiCrMo indefinite chilled nodular castiron rolls(Ⅱ) | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 1.01-2.00 | 0.30-1.20 | 0.20-0.80 |

Nodular pearlitic rolls(SGPI) | 2.90-3.60 | 1.40-2.20 | 0.40-1.00 | ≤0.15 | ≤0.03 | 1.50-2.00 | 0.10-0.60 | 0.20-0.80 |

Nodular pearlitic rolls(SGPⅡ) | 2.90-3.60 | 1.20-2.00 | 0.40-1.00 | ≤0.15 | ≤0.03 | 2.01-2.50 | 0.20-1.00 | 0.20-0.80 |

Nodular pearlitic rolls(SGP Ⅲ) | 2.90-3.60 | 1.00-2.00 | 0.40-1.00 | ≤0.15 | ≤0.03 | 2.51-3.00 | 0.20-1.00 | 0.20-0.80 |

Centrifugally acicular nodular cast iron rolls(SGAⅠ) | 2.90-3.60 | 1.20-2.20 | 0.20-0.80 | ≤0.10 | ≤0.03 | 3.01-3.50 | 0.20-1.00 | 0.50-1.00 |

Centrifugally acicular nodular cast iron rolls(SGAⅡ) | 2.90-3.60 | 1.00-2.00 | 0.20-0.80 | ≤0.10 | ≤0.03 | 3.51-4.50 | 0.30-1.50 | 0.50-1.00 |

NiMo nodular cast iron roll( Ⅰ) | 2.90-3.50 | 1.50-2.40 | 0.40-0.80 | ≤0.05 | ≤0.03 | 1.00-2.50 | 0.10-0.50 | 0.40-0.80 |

NiMo nodular cast iron roll( Ⅱ) | 2.90-3.50 | 1.20-2.40 | 0.40-0.80 | ≤0.10 | ≤0.03 | 2.51-3.50 | 0.10-0.50 | 0.40-1.00 |

Physical Performance:

Products | Barrel Hardness (HSD) | Neck Hardness (HSD) | Tensile Strength (Mpa) |

CrMo semi-chilled nodular cast iron rolls | 40-55 | 35-55 | >300 |

CrMo indefinite chilled nodular cast iron rolls | 55-70 | 35-55 | >300 |

NiCrMo indefinite chilled nodular cast iron rolls(Ⅰ) | 55-70 | 35-55 | >300 |

NiCrMo indefinite chilled nodular cast iron rolls (Ⅱ) | 60-70 | 35-55 | >300 |

Nodular pearlitic rolls (SGPI) | 60-70 | 35-55 | >450 |

Nodular pearlitic rolls (SGPⅡ) | 55-65 | 35-55 | >450 |

Nodular pearlitic rolls (SGP Ⅲ) | 62-72 | 35-55 | >450 |

Centrifugally acicular nodular cast iron rolls(SGAⅠ) | 55-78 | 32-45 | >350 |

Centrifugally acicular nodular cast iron rolls(SGAⅡ) | 55-78 | 32-45 | >350 |

NiMo nodular cast iron roll( Ⅰ) | 42-52 | 32-43 | >300 |

NiMo nodular cast iron roll( Ⅱ) | 42-52 | 32-43 | >300 |

Quotation Elements

| ITEM | QUOTATION ELEMENTS |

1 | What kind of products the factory produce? Hot Rolled Steel Coil? Cold Rolled Steel Coil? Wire Rod? Rebar? |

2 | Production Process of Roll --Cast or Forged |

3 | Grade of Roll |

4 | Chemical Composition of Roll |

5 | Physical Property of Roll: Hardness/Tensile Strength/Elogation/Bening Strength |

6 | Drawing of Roll |

7 | Quantity |

8 | Delivery time |

Quality Control and Package

Products Display

- Q:Big brother on the 1 floor is exaggerating. It's impossible at all

- If the precision of the thread is not high enough, it can be produced by pressing.

- Q:Use of waste cemented carbide

- Two, crushing methodFor hard alloy containing drilling is not high, because the hardness is relatively low, can use manual or mechanical means broken to a certain fineness in wet grinding mill for a period of time, to reach a certain size for reproduction of hard alloy. This force is a method has the advantages of simple process, short process, low energy consumption, no pollution to the environment, but often in the manual crushing hard alloy, metallic materials due to debris into the tools have broken material pollution, in addition, due to the hard alloy drill containing high amount of easily broken, mechanical crushing method is very limited; cemented carbide complex material by this method is also very difficult to ensure the quality of recycled products. Process method: artificial crushing is broken, crushed into powder 200 mesh or using bulk of hard alloy ball mill for crushing strikes the ball, then add in the bjm alcohol in wet grinding, and then enter the remanufacturing process of hard alloy.Some companies use cooling method: first crushing waste hard alloy in a muffle furnace heated to 80 above this immediately into the water quench, resulting in hard alloy cracking, and then enter the mechanical crushing process. This force is a method in the last century in 90s in Hebei Province Qinghe to gain popularity, there were dozens of county size ranging from recycling plant using the recycled and processed hard alloy, hard alloy processed over a thousand tons of annual production, the total output value of 300 million yuan, becoming one of the local pillar industry. At present, there is still a certain space for development of the crushing method, and the crushing method still needs to be improved by adopting more advanced and clean crushing equipment or by means of the force method which does not destroy the microstructure of cemented carbide with high efficiency.

- Q:What kind of industry can use carbide?

- Blade material used in mechanical processing

- Q:What materials are hard alloys used to process?

- YT hard alloy, resistant to impact, high temperature, processing steel, aluminum and so on.

- Q:What kind of cemented carbide is used for processing HRC40 degrees stainless steel?

- It is recommended to choose YS8 welding tool. Very good processing quality can be obtained.

- Q:Can CBN wheels grind cemented carbide? Why?

- Cubic boron nitride grinding should not hard alloy and non-metallic hard materials in grinding, high temperature, CBN in alkaline aqueous solution will produce a chemical reaction, CBN wheel can be decomposed in 300 DEG C in alkaline solution, can trace decomposition in boiling water, the crystal grains were damaged, so the grinding, can only use oily the cooling liquid, and can not use water-based coolant.CBN wheel grinding for mild steel, heat-resistant steel, high hardness alloy steel precision grinding and finish grinding. The special steel products such as tungsten, molybdenum and cobalt high speed steel, alloy steel, high-speed steel with special grinding, super finishing machining of heat-resistant parts, and other steel quenching workpiece grinding line.

- Q:Are there any German products called K44 which are imported into cemented carbide materials? I am machining hole, K44 is better than domestic material K30?

- Germany never heard of K44, I know K40 is the international organization for standardization as the equivalent of the national standard YG-10H, the hardness of about 1300HV, used for processing softwood or hardwood and nonferrous metal; K30 is equivalent to the national standard YG-8, the hardness of about 1400HV, suitable for low hardness of grey cast iron, low tensile strength steel and compressed wood.Compared with the two, K40 has higher toughness, but its wear resistance is lower.

- Q:5 meters long hard alloy bars, where are they sold?

- Almost impossible to sell, you can choose to use media, multi section welding, bonding completed.AskMultistage welding? What welding is it?Chasing the answerUsing a steel as the matrix, the copper inserts are used to complete the desired specifications.

- Q:Make cutting dosage

- YT for steel, steel castings, aluminum parts, not shock resistance. YG is used for rough cast iron parts, cast iron parts, shock resistance and high temperature resistance.

- Q:What is the hardness of cemented carbide?

- Different grades, different hardness, usually (86 ~ 93HRA, equivalent to 69 ~ 81HRC);

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roller for Steel Rolling Mill Forged Mill Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords