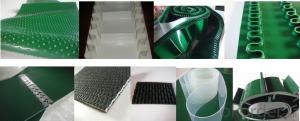

Roll Material Green Rough Top PVC Conveyor Belt 5.0mm 5.5mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Roll Material Green Rough Top PVC Conveyor Belt

PVC/PU Conveyor Belt

With advanced coating machine and other excellent facilities, we are professionally producing PVC&PU light conveyor belts, which are extremely suitable for light industry such as beer industry, paper making industry, food industry, textile industry etc.

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise (LdB belts)

* Working temperature ranges from -10 to 80Deg.C

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Please contact us freely if you need any conveyor belt.

- Q:How do I see if the plastic cup is qualified?

- As a result, the identification of plastic varieties has become simple and easy, and the cost of recycling has been substantially reduced. Today, many countries in the world have adopted the SPI logo scheme. China enacted almost identical labeling standards in 1996.

- Q:How do olive nets affect the air circulation around olive trees?

- Olive nets can impede the natural air circulation around olive trees. The nets create a physical barrier that restricts the flow of air, potentially reducing the exchange of gases and trapping stagnant air. This can lead to increased humidity levels, limited ventilation, and may create a favorable environment for the growth of fungal diseases.

- Q:Do olive nets affect the water and nutrient uptake of olive trees?

- Yes, olive nets can have an impact on the water and nutrient uptake of olive trees. These nets are used to protect the olives from birds and other pests, but they can also create a barrier that affects the tree's ability to absorb water and nutrients from the soil. The nets reduce the amount of rainfall and irrigation water that reaches the tree's roots, and they can also limit access to sunlight, which is essential for photosynthesis and nutrient uptake. Therefore, it is important to monitor and manage the use of olive nets to ensure that they do not negatively impact the water and nutrient uptake of olive trees.

- Q:How to classify waste plastics? Identification methods?

- The rapid development of the plastics industry also brings a series of social problems caused by waste plastics, waste plastics and waste plastics which people are unwilling to see. Plastic products have been applied to every corner of society. From industrial production to basic necessities of life, plastic products are everywhere. People began to find that the plastic garbage has quietly come to us, seriously affect our health and living environment, such as agricultural land due to the impact of waste plastic and waste plastic production began, triggered by the "white pollution" to make people headache, not decay decomposition boxes can not be effectively recovered, with plastic life the garbage can not start treatment...... The sharp increase in plastic waste and the social and environmental problems caused by it are placed in front of people and placed in the place where people live and live all over the world.

- Q:How are olive nets removed after harvesting?

- Olive nets are typically removed after harvesting by carefully lifting and gathering them from the ground. The olives are first collected from the nets, and then the nets are rolled or folded up for storage until the next harvest season.

- Q:Do olive nets affect the quality of harvested olives?

- Yes, olive nets can affect the quality of harvested olives. While they serve the purpose of preventing olives from falling to the ground and potentially getting damaged or contaminated, improper use of nets or leaving olives on the tree for too long can lead to overripe or spoiled olives. Additionally, if the nets are not properly cleaned and maintained, it can result in mold or fungal growth on the olives, affecting their quality. Therefore, it is important to use olive nets correctly and harvest the olives at the appropriate time to ensure optimal quality.

- Q:Can olive nets be used in combination with soil erosion prevention techniques?

- Yes, olive nets can be used in combination with soil erosion prevention techniques. Olive nets are commonly used in olive groves to protect the fruit from birds, but they also have a secondary benefit of reducing soil erosion. The nets act as a physical barrier that prevents rainwater from directly hitting the soil surface, reducing the impact of water runoff and soil erosion. Additionally, when properly installed, the nets can help retain moisture in the soil, further reducing erosion. Therefore, incorporating olive nets into soil erosion prevention techniques can provide an effective and sustainable solution to combat soil erosion in olive groves.

- Q:Can olive nets be used to reduce the risk of soil erosion in areas with high rainfall?

- Yes, olive nets can be used to reduce the risk of soil erosion in areas with high rainfall. Olive nets are designed to cover the soil surface and prevent rainwater from directly hitting the ground, thus reducing the impact of heavy rainfall on soil erosion. Additionally, olive nets help to retain moisture in the soil and promote the growth of vegetation, which further helps in preventing erosion.

- Q:Do olive nets protect against hail damage?

- No, olive nets are not designed to protect against hail damage. They are typically used to prevent birds from eating the olives, not to shield against hailstorms.

- Q:What harm does it take to eat hot food with plastic?

- If a plastic bag containing more than 50~60 degrees of food is used, the lead in the bag will dissolve into the food, and the plastic bag will release poisonous gas and invade into the food. Long term intake of the human body can seriously impair health and cause disease. Especially hot food, high temperature will make the poisonous substances in plastic absorbed by food, once entered the body will cause accumulation of towel poison, so when the hot food, must not mess with plastic bags.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roll Material Green Rough Top PVC Conveyor Belt 5.0mm 5.5mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords