Refractory Grade Calcined Bauxite 80 PCT Sands

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Grade Calcined Bauxite 80 PCT Sands

Calcined Bauxite Introduction

Property | Specifications |

Name | aluminous soil ; bauxite |

Color | White, offwhite, auburnish yellow or light red (with Fe) |

Bulk Density | 2.55~3.6 g/cm3 |

Hardness | 1~3 |

Main usages | 1. Aluminium metallurgy 2.Refractory |

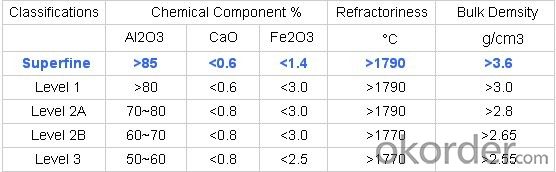

Calcined Bauxite Specifications

Size:

Sized Sand: 0~1mm

1~3mm

3~5 mm

5~8mm

8~12mm

Fine Powder:

100mesh

180mesh

240mesh

320mesh

Calcined Bauxite Applications

1. Aluminium metallurgy

2. Precision casting / Investment casting:

bauxite grog fines can be made into mold for precision casting.

3. Refractory: high alumina bauxite’s refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance. (Al2O3 ≥48% with low Fe2O3)

4. Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under 2000°C-2200°C in the electric arc furnace.After a series of processing, it can become aluminium silicate refractory fiber,

which can be made into fiber blanket, plate,cloth.

5. Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining

performance.

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability,

low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock.

Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy,

defense and other industries.

(5) in magnesia and bauxite clinker as raw materials, add the appropriate binder,

used for pouring ladle whole ladle lining has particularly good effects.

(6) manufacture alumina cement, abrasive materials,

ceramic industry and chemical industry can be aluminum of various compounds

Pictures:

- Q:How much is the content of boron carbide in refractory material?

- Boron carbide is used in refractory material. For example, generally we could add 0.2% of boron carbide into magnesia carbon bricks. It is suggested that 0.5% is enough, because it has strong effect in boosting melt. It is said that 0.5% would be alright since boron oxide after oxidation belongs to material of low melting point, so the amount should be limited within 0.5%-1%,

- Q:Who knows what kind of fire protection material is better?

- Characteristic of polyurethane rigid foam thermal insulation decorative composite board: (1) ultra high cost performance, increased property's selling point (high cost performance) new model of thermal insulation material, excellent thermal insulation properties, elegant decorative effect, 50 years of service life, reduce maintenance costs and social waste. (2) it overcomes defects of traditional insulation technology (to solve the freezing and thawing, veneer cracking and shedding) traditional benzene board, the phenomenon of freezing and thawing that is easily appear in plastic extruded sheet, paint finish is easy to crack; its veneer facing can easily fall off; thermal insulation materials and wall are poorly adhered, easy off the whole. There is a themal bridge in dry hanging wall. (the characteristics of polyurethane composite board)

- Q:how does the fire endurance of first rate fire resistant window?

- the classes are different. class A window not less than 1.5 hours, and the time is short, class B window not less than 1 hours, with shorter time, Class C window not less than 0.5 hours.

- Q:Who can introduce the difference between galvanized fireproof?coatings and steel structure fireproof materials?

- There is no difference between them because they are the coating with the same texture. But generally galvanized treatment is not necessarily needed for brushing fireproof coating. Fireproof coating and galvanized surface have relatively poor bond strength. So it is advisable to bursh trasitional lacquer or micaceous iron on galvanized surface.

- Q:Who knows about the criteria of fireproof and thermal insulation materials?

- Seven levels are divided according to "The classification of combustion performance of building materials and products", namely, A1, A2, B, C, D, E, F. It mainly refers to the combustion performance of materials. You can check on this standard for the specific dividing evidence. There are detail charts which mainly describe that whether there is drip or not, the ignition time, continuous burning time and so on.

- Q:What are the characteristics of clay refractory materials?

- Clay refractory has excellent performance in anti fatigue. The fatigue strength of the general metal is 50% ~ 40 of the tensile strength, and some composite materials can be as high as 70 ~ 80%. The fatigue fracture of the composite is from the matrix, which is gradually extended to the interface between the fiber and the matrix. Therefore, the composite material has omen before destruction, and it can be checked and remedied. Fiber composite material also has good performance in anti vibration fatigue. The fatigue life of The helicopter rotor made of composite material is longer that made of metal. I hope my answer will help you!

- Q:What are the specifications of fireclay bricks?

- Hello: I'm glad to answer your questions! Sizes of refractory brick (mm) 230 * 114 * 65 Xiaoshang Refractory Materials Factory in Zibo city has a relatively large market share, and the products are of high quality at a price of 490 yuan per ton. The cost performance is relatively high and the products are popular in the industry. I hope my answer will be helpful to you.

- Q:Which are fireproofing external wall materials?

- For example, Grade-A waterproofing external wall thermal insulation material: glass wool, foam glass, foam cement, hole-closed perlite, rock wool; Grade-B1 waterproofing external wall thermal insulation material: XPS after special treatment. There are also PU after special treatment, phenolic aldehyde and gelatine powder polyphenyl granule. Grade-B2 waterproofing external wall thermal insulation material: PE, and EPS. Grade-A: Completely fireproofing buliding material. Without probility of burning, completely fireproofing buliding material is expensive and unnecessary for home decoration. It is usually used in arsenal and electrical equipment department store. Grade-B1: nonflammable building material: With good flame resistance, nonflammable building material will not burn in the air or at high temperature, but it maby burn in the air and at high temperature. But when the fire source ransfers, it will be out immediately. Grade-B2: combustible building materials. Due to its small firresistance, it is easy to burn in the air or at high temperature, such as wooden building materials. The above are external wall fireproofing material of different classes.

- Q:What is the function of refractory material?

- Refractory is a basic material in the field of high temperature technology. Generally, the refractory is used as structural material or lining to resist high temperature in various thermal equipment and high temperature container. In the iron and steel industry and metallurgy industry, coke ovens are mainly composed of refractory materials. Various refractories that meet the requirements are essential in blast furnace for ironmaking, hot stove, all kinds of steel-making furnaces, soaking furnace and heating furnace. Not only the die casting for molten steel needs lots of refractory materials, but also the continuous casting needs some high-quality refractory materials. Without high-quality refractory materials, external refining is also not impossible to achieve. Statistics show that the steel industry is the sector that needs the most refractory. Pyrometallurgy and thermal processing of ferrous metal also needs refractories. All high-temperature furnaces or lining in construction materials industry or other high temperature industries that produce silicate products such as glass industry, cement industry, and ceramics industry must be constructed with refractory materials. All kinds of roasting funaces, sintering funaces, heating furnaces, boilers, flues, chimneys and protective layers in chemical, power and machinery manufacturing industry need refractories. In short, when some kind of structures, devices, equipments or vessels are used under high temperature, they all should utilize refractory to resist the high temperature because those materials will deform, soften and fuse or will be eroded, scoured or broken due to the physical, chemical, mechanical effects, which may stop the operation, affect the production, contaminate processed objects and impact the quality of products.

- Q:How to divided the grade of external wall thermal insulation materials?

- 1, According to China's national standard GB8624-97, combustion performance of building materials will be divided into the following grade level A: Incombustible building material: It is a kind of material that almost does not occur burning. Level B1: Nonflammable building material: Non-flame material has good flame resistance. It is difficult to fire under the condition of open fire in the air or high temperature, and it is not easy to quickly spread, and when the combustion?source is removed, the combustion will stop immediately. Level B2: Combustible?building?materials: Flame material has a good flame resistance. In case of fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as wooden column, timber roof truss, timber beam and wooden stairs. Level B3: Combustible?building?materials: It has no any flame resisting effects, and is easy to burn, so the fire risk is high. 2, The external wall thermal insulation materials is divided by fire rating 1) level A combustion performance thermal insulation material Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. I hope my amswers are helpful to you

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Grade Calcined Bauxite 80 PCT Sands

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords