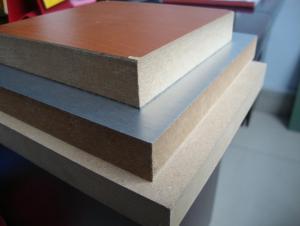

Red Oak Veneered MDF Panels Medium Density Fiberboard

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description:

Red oak veneered MDF are usually be used in decoration and furniture.

Characters:

Light, easy to install, disassemble and beautiful.

Products Details:

Detailed Specification:

Product name: Red oak veneered MDF

Size: 1220*2440mm

Thickness: 4mm

length/width tolerance: +/- 0.5mm

thickness tolerance: +/- 0.2mm

glue: E1,E2,E0

moisture: 6~12%

packing: seaworthy export pallet packing,strengthen by steel tape with 3*6 or loose packing in containers

loading quantity: 21.5CBM per 20'container

minimum order quantity: one 20'container

usage: used for furniture

payment term: by T/T or L/C at sight

delivery time: within 20 days after we got your advance payment

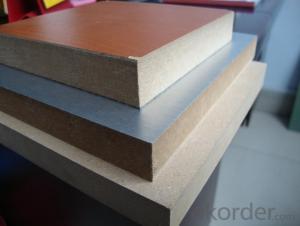

2. Packing Details of Red oak veneered MDF

Four sides are around with MDF in thickness ≥4mm,

Top cover is thin MDF in thickness ≥ 8mm,

Bottom board is MDF in thickness ≥12mm ,

4+8 steel strips.

FAQ:

Q1. How long can we receive the product after purchase?

A1: Normally, cargoes can be shipped within 25days if the paper are in fast-moving colors; however, if colors are special need to be matched, then, we need at least one month to prepare and produce

- Q:Decoration house, mud carpenter approach, the need to pay attention to what the problem?

- , carpentry should bring their own toolbox, workstations, air compressors and other commonly used tools, especially the table must not let the decoration workers to buy wood with the owner made, before the decoration must be with the decoration company or decoration team foreman clear The The following are the same as the "

- Q:Do you want to paint the panel, what panel?

- Best to plywood. 1, paste Austrian song board. Austrian pine board is more delicate, make the paint better effect. But limited to mixed oil.

- Q:What is called a panel?

- Three hydrogen ammonia plywood, specifications are: 1.22 * 2.44m, 1.22 * 3m, generally used for furniture or interior decoration!

- Q:Do the furniture of the woodworking board need to be plywood?

- Wood panels need to plywood, finger board can not

- Q:What is the difference between a whitewash board and a veneer?

- It is made of natural wood slicing or peeling into the thickness of 0.2-1mm thin slices, after the parquet paste in the plywood, fiberboard, particleboard and other substrates made of.

- Q:What is an ecological board? Can be used to do?

- Jinliyuan in Hangzhou, they are facing the country, the old reputation, reassuring

- Q:Woodworking desk, too long, paste the panel after the varnish will have how to deal with seams ah

- If you need to extend the desk, the original design should be in accordance with the decorative panel to design the collage.

- Q:Home improvement commonly used plate which?

- MDF process: also known as fiberboard. To wood fiber or other plant fiber as raw material, the application of urea-formaldehyde resin or other suitable adhesive made of surface treatment is mainly mixed oil process.

- Q:What are the quality requirements for decorative panels?

- Decorative panels - the construction quality requirements: First, first of all depends on the floor of the panel is flat, solid Second, depends on the panel texture direction or pattern is not one to third, look at the face of the panel is empty , Look around the panel is not sticky

- Q:What is the difference between solid wood veneer doors and solid wood composite doors?

- Shi Mu Square of the uniform use of 8 miles thick, which all solid wood, cost is high, the key recommendation!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Red Oak Veneered MDF Panels Medium Density Fiberboard

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords