Furniture Plain MDF board Raw MDF Sheet Melamine MDF

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

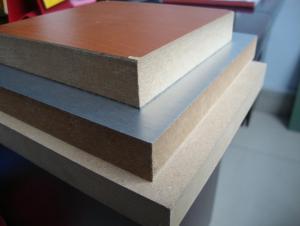

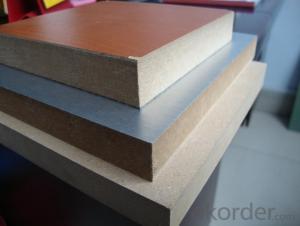

Specification

size:1220*2440mm

thickness:2.5-25mm

Surface process: Satin, glossy, pearl,many colors are available

Description

Size | 1220*2440mm, 1830*2440mm,1830x3600mm,ect. |

Thickness | 2.5-25mm(9mm,12mm,15mm,16mm,17mm,18mm,20mm,25mm) |

glue | E1/E2 |

moisture | Less than 8% |

color | more than 300 kinds color surface |

material | wood fiber |

density | 9mm--25mm:720-780kg/M3; 2.5mm--8mm:780--860kg/m3 |

Screw holding face | 1300N |

Screw holding edge | 800N |

certificate | ISO9001,9002, ISO14001, CARB |

Main market | Europe,Middle East,Africa,South Asia,South America and North America |

Features

high bending strength

low formaldehyde emission

little linear expansion coefficient

strong nail holding

moisture proof and easy work , moisture content 4%~6.6

FAQ

A. how many sheets for one cubic meter?

Answer:

6mm---56 sheets/CBM

9mm---37.33 sheets/CBM

12mm---28 sheets/CBM

15mm---22.40 sheets/CBM

18mm---18.66 sheets/CBM

21mm---16.00 sheets/CBM

B. how many cubic can load for one container?

Answer:

20FT---21.4 cbm 40ft---37 cbm

- Q:Embossed drawing veneer

- Three-dimensional and convex sense of a strong visual effects, in the LOFT style platform to be played by the most environmentally friendly level: E0 level features: pine fine texture, texture straight, after the anti-corrosion treatment, can effectively prevent mold, termites, microbial invasion Boring, the advanced technology effectively inhibit the changes in wood moisture content, wood deformation, no cracking, high density, beautiful texture, polished feel more delicate.

- Q:What is the double-panel, wardrobe with this back to do it?

- Double-sided can not look at the main material environmental protection is not

- Q:What is the price of decorative veneer?

- The decorative panel is a special way that the plywood is present, with a thickness of 3%.

- Q:Melamine plywood and fire board plywood which is good?

- Although both in the veneer materials contain the same resin, but the thickness, the structure of the different, resulting in significant differences in performance. The two can not be generalized.

- Q:What are the advantages and disadvantages of decorative panels?

- Melamine veneer makes the appearance of furniture strong, printed with color or imitation wood grain of paper itself is fragile, melamine plate in the transparent resin soaked in the formation of the film after the film to be hard, this film and the substrate hot pressing Into a body has a very good performance, with it to fight the furniture do not have to paint, the surface of the natural formation of protective film, wear, scratch resistance, Naisuan Jian, resistant to heat, pollution.

- Q:Melamine plywood (do board with the board) dirty how to clean

- Sichuan creative science and technology of melamine board is very good Kazakhstan, the brand "law is still" is the China Interior Decoration Association recommended products.

- Q:What is the thickness of the trim panel?

- The thickness of the panel is usually 3mm, but there are some other thickness of 0.9mm, 1.2mm, 1.5mm, 1.8mm, 2.0mm, 2.7mm / 3.0mm, 3.6mm, etc., the thicker the better the performance, The more true, the more clear texture, bright color saturation is good.

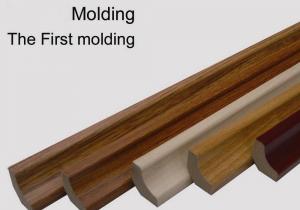

- Q:How many types of wooden lines

- Second, the protective effect, especially in the panel of the mouth of the mouth, if not to protect the line, the future use of the process of the surface of the panel can easily be scratched, affecting the use.

- Q:How to identify the furniture board is good or bad

- See the hardness of the wrench, hardness is also higher that the better the density.

- Q:What are the quality requirements for decorative panels?

- One: veneer in two kinds: Ma face and smooth, feel good plate flat no bubbles, stickers without broken. Second: the substrate is divided into two categories, MDF and particleboard, a tough degree of environmental protection is difficult to achieve poor water resistance. There are many kinds of wood-based substrate, the substrate is waterproof, the substrate can not have impurities (iron and stone) formaldehyde can not exceed the standard (no pungent odor) see you use dew river plate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Furniture Plain MDF board Raw MDF Sheet Melamine MDF

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords