QB Series Peripheral Water Pump with Brass Impellers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 400 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Application of the pump:

1> Clean Water without abrasive particles, non-aggressive liquid.

2> Domestic use.

3> In particular for delivering water in combination with small pressure sets and for irrigation.

4> Installed in enclosed places, or at least protected against inclement weather.

2. Operating conditions.

1> Suction lift up to 8m.

2> Liquid temperature up to +40℃

3> Ambient temperature up to +40℃。

4> Max. working pressure: 6bar.

3. Motor description:

1> 2-pole induction motor: 50Hz.

2> Insulation: Class B.

3> Protection: IP44.

4> With capacitor and thermal overload protection.

4. Material of the pumps:

1> Pump body: Cast Iron.

2> Motor bracket: Aluminum.

3> Impeller: Brass.

4> Shaft with rotor: Stainless steel or CS45#

5> Mechanical seal: Ceramic-Graphite.

6> Copper Winding.

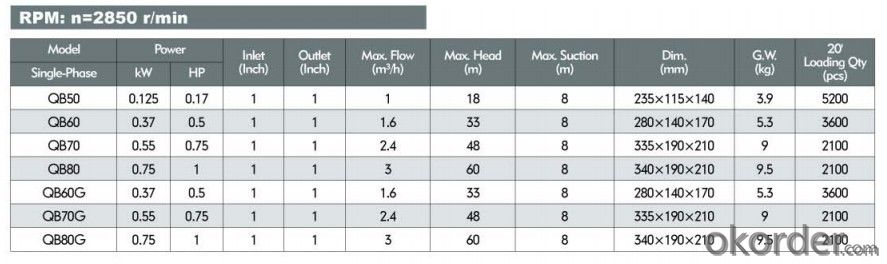

5. Detailed specification for the pumps:

6. FAQ

1). Can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

2). Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

3). How long is your warranty?

Unless otherwise expressly authorized in writing, by specifying a longer period or different conditions, CNBM states that, for a period of twelve (12) months from delivery date, all Products supplied are free from defects in materials and workmanship, and conform to the applicable specifications. Either the delivery documentation or the invoice must be provided to prove delivery date. In absence of such documents, the production date appearing on the product label may suffice.

- Q:What is the lift of diaphragm pump?

- Diaphragm pump lift is different from the centrifugal pump, refers to the diaphragm pump can raise the height of water, the unit is meters water column. Lift depends on the size of the outlet pressure, the pressure per kilogram is equivalent to 10 meters height

- Q:If the calculation of the required pump flow is 45, lift 110, and the actual pump flow 100, head 125, what will happen in operation? Can I use it properly?

- The air pump.The pump itself is mechanical failure.The pump outlet valve core off.Low voltage power.

- Q:Bolus dosage of infusion pumpWhat is the purpose of the pill dose control in the special safety standard for infusion pumps? If the risk is not properly controlled, what is the degree of risk? And how can the open infusion pump be used in this regard?

- (three) infusion limited number of pills produced after the dose of obstruction by infusion pump and specification of the matching test, will reach acceptable when the storage pressure of the pressure to determine the alarm blocking. Thus, some have restrictions on the infusion tube blocked after the maximum dose pill may have blocked the trigger before the alarm.

- Q:Why is the flow of the pump too small will occur cavitation phenomenon?

- Why is it easy to produce cavitation when the inlet flow of pump is lowered?This is because the main performance parameters such as the head, power and efficiency of the centrifugal pump are not fixed, but vary with the flow rate. The curve drawn on a coordinate paper is called the performance curve or characteristic curve of the centrifugal pump. What happens when the flow rate decreases? The disadvantage of throttling adjustment is that the pump flow is small, and the impeller is easy to cause cavitation

- Q:What's the meaning of the pump head in the water pump, please advise, thank you

- In general, the pump removes the motor, and all the fittings are part of the pump head.A pump is a machine that transports liquids or pumps liquids.

- Q:What's the difference between non negative pressure and variable frequency water pump?

- Re pressure to a given pressure pressure zone water supply, than frequency conversion water pump energy savingFrom a health perspective, a water tank variable frequency water pump, water tank and the atmosphere, easy occurrence of water pollution two, no negative pressure equipment without negative pressure tank and pump and valve fittings etc., no water tank, the whole process of water supply of water is completed in a closed system, with air contact to avoid two pollution problems water supply.From the management point of view, no negative pressure is fully automatic intelligent operation, reduce management costs, no water tank, reducing the trouble of tank cleaning. No negative pressure is the upgrading of variable frequency water pump products

- Q:How much water does the water ring vacuum pump run for an hour? If there is no steam separator, does the water vaporize?

- For example: water storage is relatively small, it needs to reduce the temperature of the heat exchanger. If the tank is relatively large, it does not need cooling water circulation pump again when the temperature is very low, there is no need to heat exchanger. So you need to ask how much water this is not OK.In a soda separator problem:

- Q:No negative pressure water supply equipment, both the main pump and auxiliary pump, power is not the same, how to choose the control cabinet?

- Non negative pressure water supply equipment can be divided into non negative pressure tank and box type non negative pressure compensation device, steady flow tank type non negative pressure water supply equipment is the negative pressure tank, pressure tank can eliminate the negative effect of network equipment, is equipped with a vacuum suppressor and water protection box; non negative pressure water supply equipment has the advantages of simple device is a water tank with the boost voltage stabilizing device of complex box at the same time with no negative pressure tank.The tank type non negative pressure water supply equipment adopts vertical multistage centrifugal pump. This kind of pump is low noise and high efficiency. Such as CDL series and imported CR seriesOrdinary box type non negative pressure water supply equipment can use multi-stage centrifugal pump, also can use stainless steel submersible pump, submersible pump costs will be lower, but the maintenance costs will be high.

- Q:What's the pump? Where can I use it?

- A pump is a machine that transports liquids or pumps liquids. Pumps are ubiquitous in life. They can be used to transport liquids such as water, oil, acid and alkali, emulsions, suspensions and liquid metals, as well as liquids, gas mixtures, and liquids containing suspended solids.

- Q:What are the advantages and disadvantages of the pump control system and valve control system in the hydraulic system? How to choose in the project?

- Valve control system is generally used for open systems, through the proportional valve or servo valve flow changes to control the motor or cylinder actuator action. The advantages of the system are energy saving, heat generation, and control accuracy. The disadvantage is that the system is complex and the cost is higher.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

QB Series Peripheral Water Pump with Brass Impellers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 400 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products