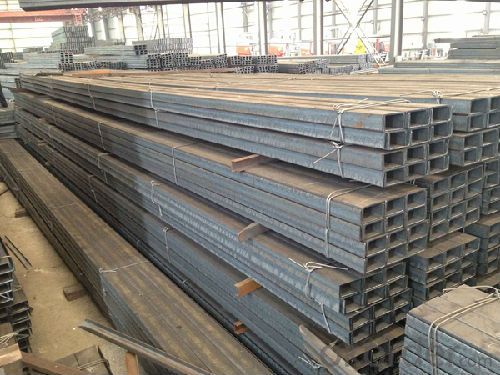

Q235 Hot Rolled Channel Steel With High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Q235 Hot Rolled Channel Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Q235 Hot Rolled Channel Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Q235 Hot Rolled Channel Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Description:

1. We are definitely specializing in manufacturing and supplying channel steel.

Standard: | GB |

Material/Grade: | Q235 |

Sizes: | 50mm to 280mm |

Sales Volume/Year: | 3000MT |

Destination Area: | Middle East, Africa, Southeast Asia |

2.Size, Length and Mass.

Size(mm) | Length(m) | Mass(Kg/m) |

180*68*7.0*10.5 mm | 6m, 12m | 20.174 kg/m |

180*70*9.0*10.5 mm | 6m, 12m | 23.000 kg/m |

Package & Delivery of Channel Steel:

The steel u channel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

And steel u channel could be loaded into 20ft or 40ft container, or by bulk cargo. If the weight of each bundle reaches less than 3.5 mt, the loading by break bulk cargo should be choosed. When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

All in all, we could do in accordance with customer's request.

Trade terms: FOB, CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q:Can steel channels be used in the construction of retaining walls?

- Yes, steel channels can be used in the construction of retaining walls. Steel channels provide strength, durability, and flexibility, making them suitable for supporting soil and resisting lateral pressures. They can be used as primary structural elements or as reinforcement in various retaining wall designs.

- Q:Are steel channels suitable for the mining manufacturing industry?

- Yes, steel channels are highly suitable for the mining manufacturing industry. Steel channels are commonly used in various industries, including mining, due to their excellent strength and durability. The mining industry requires heavy-duty equipment and machinery that can withstand harsh conditions and rigorous use. Steel channels, being made of a strong and robust material, can provide the necessary support and structural integrity to handle the demanding requirements of the mining manufacturing industry. Moreover, steel channels offer versatility in terms of design and configuration, allowing them to be used in a wide range of applications within the mining industry. They can be used to construct frameworks, support structures, conveyor systems, and other equipment necessary for mining operations. Furthermore, steel channels have high load-bearing capacities, which is essential in the mining industry where heavy loads and vibrations are common. They can efficiently distribute weight and handle stress, ensuring the safety and reliability of mining equipment and structures. Additionally, steel channels are resistant to corrosion, making them suitable for use in the mining industry where exposure to moisture, chemicals, and other corrosive substances is prevalent. This corrosion resistance prolongs the lifespan of the equipment, reducing maintenance and replacement costs. In conclusion, steel channels are highly suitable for the mining manufacturing industry due to their strength, durability, versatility, and resistance to corrosion. They provide the necessary support and structural integrity required for heavy-duty mining equipment and structures, making them a reliable choice for various applications within the industry.

- Q:What are the different methods for protecting steel channels from corrosion?

- There are several methods available for protecting steel channels from corrosion. Here are a few of the most common ones: 1. Coating: One of the most effective methods is to apply a protective coating on the surface of the steel channels. This can be done using paints, epoxy coatings, or galvanizing. Coatings act as a barrier between the steel and the corrosive elements in the environment, preventing direct contact and corrosion. 2. Cathodic protection: This method involves using a sacrificial metal or an impressed current to protect the steel channels. Sacrificial metal, such as zinc or magnesium, is connected to the channels. These metals are more reactive than steel and corrode in place of the channels. Impressed current systems involve the use of an external power source to generate an electric current that counteracts the corrosion process. 3. Corrosion inhibitors: These are chemicals that can be applied to the steel channels to slow down or prevent corrosion. Corrosion inhibitors work by forming a protective layer on the surface of the channels, which inhibits the reaction between the steel and the corrosive elements. 4. Design considerations: Proper design and construction practices can also help protect steel channels from corrosion. This includes ensuring proper drainage and ventilation to reduce moisture buildup, avoiding crevices and areas where water can accumulate, and using materials that are less susceptible to corrosion in corrosive environments. 5. Regular maintenance: Regular inspections and maintenance, such as cleaning and removing any accumulated debris or dirt, can help identify and address potential corrosion issues early on. This can include reapplying coatings, repairing damaged areas, or replacing corroded sections of the steel channels. It is important to note that the choice of protection method depends on factors such as the environment, the expected service life of the channels, and the budgetary constraints. Consulting with corrosion experts or professionals in the field can help determine the most suitable method for protecting steel channels from corrosion in a specific application.

- Q:Can steel channels be used for conveyors?

- Yes, steel channels can be used for conveyors. Steel channels are typically used in conveyor systems to provide structural support and stability. They are commonly used as the framework for the conveyor system, providing a sturdy base for the other components such as rollers, belts, and motors. Steel channels offer high strength, durability, and resistance to wear and tear, making them suitable for handling heavy loads and prolonged use. Additionally, steel channels can be easily customized and fabricated to meet specific conveyor requirements, allowing for flexibility in design and installation.

- Q:How do steel channels contribute to acoustic performance?

- Various applications can benefit significantly from the use of steel channels to improve acoustic performance. One of the main advantages of steel channels is their ability to minimize sound transmission and enhance sound insulation. When incorporated into wall or ceiling systems, steel channels act as a barrier that prevents sound from traveling between different spaces. The design and construction of steel channels allow for the installation of sound insulation materials, such as mineral wool or acoustic foam. These materials effectively absorb and dampen sound waves, reducing the transmission of noise from one area to another. By integrating steel channels into the construction of walls or ceilings, the overall acoustic performance of a space can be greatly enhanced. Steel channels not only excel in sound insulation but also contribute to the improvement of room acoustics. For instance, by utilizing steel channels to create a suspended ceiling, a more balanced and controlled sound environment can be achieved. The space between the steel channels can be filled with acoustic tiles or panels, which absorb sound reflections and minimize echoes, resulting in better speech intelligibility and overall sound quality. Furthermore, steel channels can also be utilized to support the installation of sound-absorbing materials on walls or ceilings. Materials such as fabric-wrapped panels or perforated metal sheets help reduce reverberation and echo in a room, thereby enhancing its acoustic performance. Steel channels provide a reliable framework to securely mount these materials, ensuring their effectiveness in enhancing sound absorption. In summary, steel channels contribute to acoustic performance by reducing sound transmission, improving sound insulation, and enhancing room acoustics. Whether used in the construction of walls, ceilings, or as a support for sound-absorbing materials, steel channels play a pivotal role in creating a more acoustically favorable environment, be it in residential, commercial, or industrial settings.

- Q:What are the different weight classifications for steel channels?

- Steel channels are classified based on their weight per linear foot. The weight classifications for steel channels include lightweight, medium weight, and heavy weight. Lightweight steel channels typically have a weight per linear foot ranging from 1.0 to 6.0 pounds. These channels are commonly used in applications where strength is not the primary concern and where the load requirements are relatively lower, such as in decorative or non-structural applications. Medium weight steel channels have a weight per linear foot ranging from 6.1 to 16.0 pounds. These channels are often used in structural applications where moderate strength and load-bearing capacity are required, such as in building frames, supports, and bracing. Heavy weight steel channels have a weight per linear foot ranging from 16.1 to 40.0 pounds. These channels are designed to provide maximum strength and load-bearing capacity and are commonly used in heavy-duty structural applications such as industrial buildings, bridges, and infrastructure projects. It is important to note that the weight classifications for steel channels may vary depending on the specific standards and specifications set by different countries and organizations.

- Q:How are steel channels used in the manufacturing of machinery?

- Steel channels are commonly used in the manufacturing of machinery due to their structural strength and versatility. These channels, also known as C-channels or U-channels, are typically made from hot-rolled steel and have a distinct shape resembling the letter "C" or "U". In the manufacturing process, steel channels are used for various purposes. They can be used as structural components to provide support and stability to the machinery. The channels are often used as frames or bases for equipment, providing a solid foundation for the other components to be attached to. Additionally, steel channels can be used as guides or tracks for moving parts within the machinery. By attaching rollers or bearings to the channels, machinery components can easily slide or roll along the track, enabling smooth and precise movements. Steel channels are also used as reinforcement for machinery components. They can be welded or bolted onto parts that require additional strength or rigidity. This reinforcement helps to prevent bending, warping, or distortion of the machinery during operation, ensuring its durability and longevity. Furthermore, steel channels can be used for mounting various accessories or attachments. By attaching brackets, clamps, or other components to the channels, machinery designers can easily customize and configure the equipment to meet specific requirements. Overall, steel channels play a crucial role in the manufacturing of machinery by providing structural support, guiding moving parts, reinforcing components, and facilitating customization. Their strength, versatility, and ease of use make them an ideal choice in the construction of robust and reliable machinery.

- Q:The types of channel steels are 6, 8, 10, 12, 16, 20, 25, 32 and 14. What are their tensile strength of these types of channel steel?

- Tensile strength and yield strength are independent of size and size, but only material.

- Q:Channel 10 is calculated, if the price per metre is calculated

- On the market, the sale of 10 channel steel, a lot less than the national standard weight, the general negative difference in 5% within the standard. Depending on your use requirements, the maximum negative difference may be as high as 30%.

- Q:What are the different types of bending for steel channels?

- Steel channels can be bent using various methods, including cold bending, hot bending, and press brake bending. 1. Cold Bending: To shape the steel channel without heating it, force is applied. This cost-effective method does not necessitate specialized equipment. Manual tools like hammers, pipe benders, or hydraulic benders can be utilized. Cold bending is suitable for simpler and smaller projects. 2. Hot Bending: The steel channel is heated to a specific temperature before being shaped. This technique is employed for more complex and larger bending projects, as it allows for precise and controlled bending. Induction heating or flame heating techniques are commonly used. After heating, hydraulic or mechanical force is applied to bend the steel channel. 3. Press Brake Bending: A press brake machine is employed in this method. It is highly accurate and ideal for large-scale production. The machine consists of a punch and a die. The steel channel is positioned between the punch and the die, and force is applied using the press brake to achieve the desired angle. The choice of bending method depends on factors such as the complexity of the project, the size of the steel channel, and the required precision. Each method has its own advantages and limitations, so it is crucial to select the appropriate method based on these factors to ensure the desired outcome.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q235 Hot Rolled Channel Steel With High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords