All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is cold-rolled steel utilized in the medical field for the manufacture of surgical instruments and equipment?

Cold-rolled steel is widely used in the medical field for the production of surgical instruments and equipment due to its numerous advantages. The cold-rolling process enhances the steel's strength, durability, and resistance to corrosion, making it ideal for surgical instruments that require precision, sharpness, and longevity. Additionally, the smooth and clean surface of cold-rolled steel prevents bacterial growth, ensuring a hygienic environment during medical procedures. This versatile material also allows for intricate designs and customization, enabling the production of specialized surgical instruments tailored to specific medical procedures. Overall, cold-rolled steel's superior properties make it an indispensable material in the manufacturing of surgical instruments and equipment in the medical field.

What standards and certifications are relevant for cold-rolled steel products?

There are several standards and certifications that are relevant for cold-rolled steel products. Some of the key ones include ISO 9001:2015, which ensures quality management systems are in place; ASTM A1008/A1008M, which specifies the general requirements for cold-rolled carbon steel sheets; EN 10130, which outlines the requirements for cold-rolled low-carbon steel flat products; and JIS G 3141, which sets the standards for cold-reduced carbon steel sheets and strips. Additionally, certifications like RoHS and REACH may also be relevant, ensuring compliance with environmental regulations regarding the use of hazardous substances.

Can you explain the significance of pickling and oiling in the cold-rolled steel manufacturing process?

Pickling and oiling are essential steps in the cold-rolled steel manufacturing process for various reasons. Pickling involves the removal of surface impurities and mill scale from the steel using acid baths. This process not only enhances the steel's appearance but also improves its corrosion resistance by creating a clean and smooth surface.

On the other hand, oiling is done after pickling to provide temporary corrosion protection and lubrication. A thin oil coating is applied to the steel surface, which acts as a barrier against moisture and atmospheric elements, preventing rust formation. Furthermore, it facilitates easy handling and prevents scratching or damage to the steel during subsequent processing or transportation.

Overall, pickling and oiling play a crucial role in cold-rolled steel manufacturing as they enhance the quality, appearance, and durability of the final product while ensuring optimal performance in various applications.

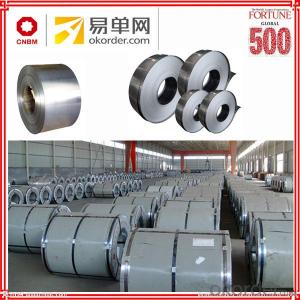

Wholesale Cold Rolled Steel from supplier in Spain

We are a Cold Rolled Steel supplier serving the Spain, mainly engaged in the sale, quotation, and technical support services of various Cold Rolled Steel products in the Spain region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Cold Rolled Steel procurement services in the Spain. Not only do we have a wide range of Cold Rolled Steel products, but after years of market development in the Spain, we can also provide valuable experience for your projects.