PVC Waterproof/waterproofing Membrane For Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

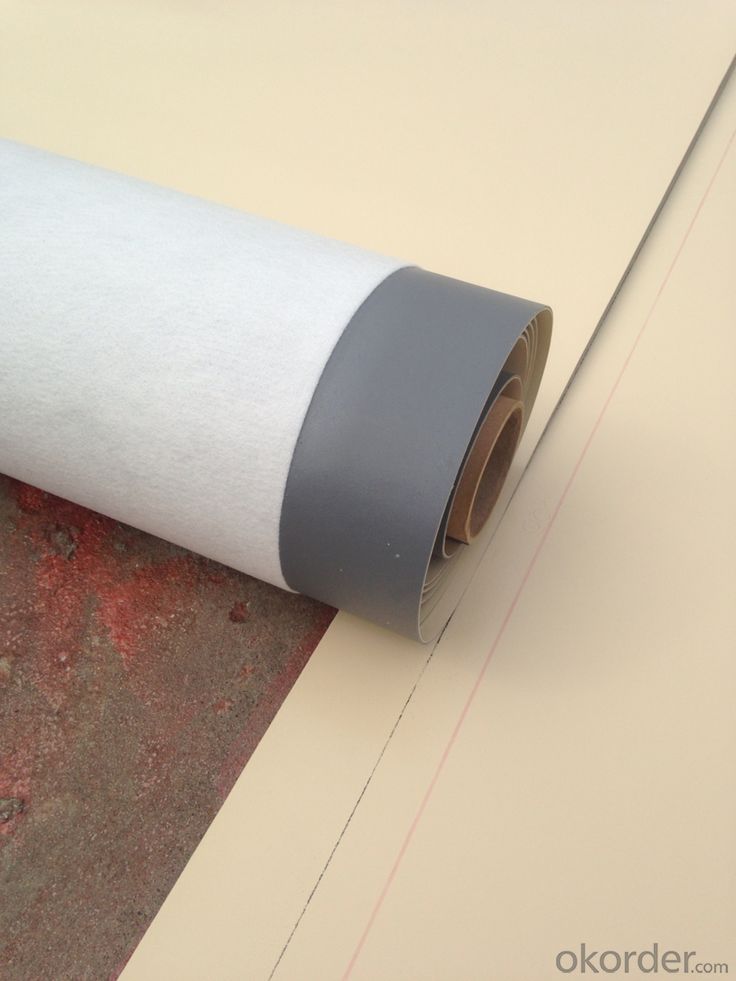

Polyvinyl chloride PVC waterproof membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

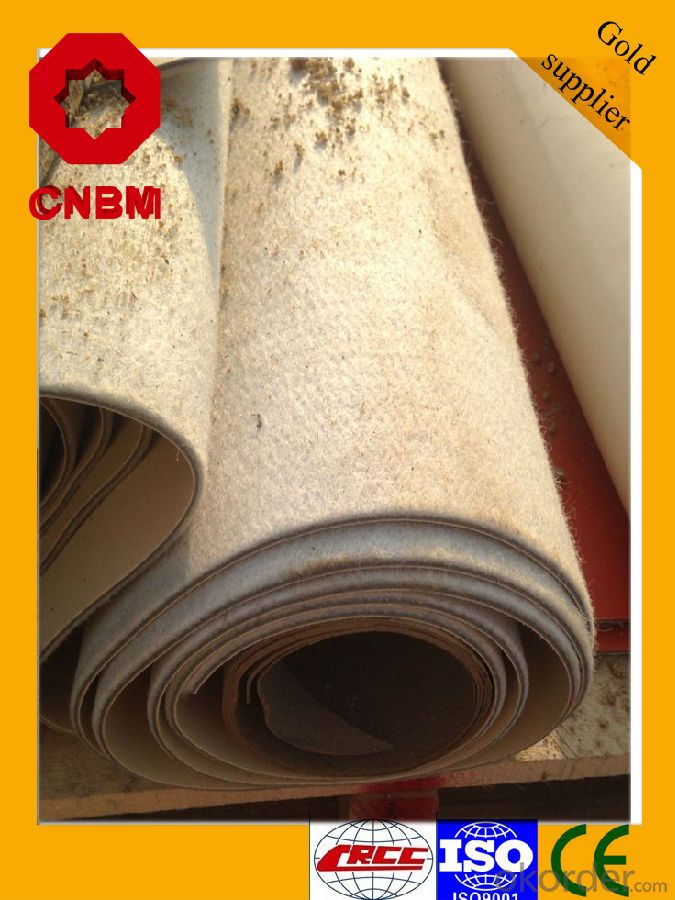

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q:Can a waterproofing membrane be used for wastewater facilities?

- Yes, a waterproofing membrane can be used for wastewater facilities. Waterproofing membranes are commonly used in wastewater facilities to prevent water leakage and seepage. They provide an effective barrier against water infiltration and protect the structure from water damage. Additionally, these membranes are resistant to chemicals and can withstand harsh environmental conditions often found in wastewater facilities.

- Q:Can a waterproofing membrane be used for restaurants or kitchens?

- Yes, a waterproofing membrane can be used for restaurants or kitchens. It provides an effective barrier against water penetration, preventing leaks and water damage. This is particularly important in areas where there is frequent exposure to water, such as kitchens and restaurant facilities. Waterproofing membranes can be applied to various surfaces like floors, walls, and even countertops, ensuring a watertight seal and maintaining a hygienic environment.

- Q:Can a waterproofing membrane be used on vinyl surfaces?

- Yes, a waterproofing membrane can be used on vinyl surfaces. The membrane serves as a protective layer that prevents water from penetrating and damaging the vinyl material.

- Q:Can a waterproofing membrane be used for underground parking structures?

- Yes, a waterproofing membrane can be used for underground parking structures. Underground parking structures are particularly vulnerable to water infiltration due to their location and exposure to groundwater. Waterproofing membranes are designed to provide a protective barrier against water penetration, preventing potential damage to the structure and its contents. These membranes are typically applied to the exterior walls and floors of the underground parking structure, ensuring a watertight seal. Additionally, the use of a waterproofing membrane can also help to prevent the formation of moisture-related issues such as mold growth, corrosion, and deterioration of concrete. Therefore, incorporating a waterproofing membrane is essential for the long-term durability and functionality of underground parking structures.

- Q:Are waterproofing membranes suitable for below-grade applications?

- Waterproofing membranes are well-suited for below-grade applications, as they are specifically designed to prevent water infiltration into structures below ground level, such as basements, foundations, and retaining walls. These membranes are constructed using durable materials, capable of withstanding soil and water pressure, thus providing long-term protection against leaks and water damage. Typically, they are installed on the exterior side of below-grade structures to create a barrier that blocks water from permeating the walls or floors. Moreover, waterproofing membranes possess flexibility, allowing them to accommodate structural movements, ensuring their effectiveness even in challenging below-grade environments. In summary, waterproofing membranes serve as a dependable and efficient solution for safeguarding below-grade structures from water intrusion.

- Q:Can a waterproofing membrane be used on tile surfaces?

- Yes, a waterproofing membrane can be used on tile surfaces. It helps to provide an additional layer of protection against water damage and helps to prevent water penetration through the tile surface and grout lines.

- Q:How does a waterproofing membrane handle expansion and contraction of the substrate?

- A waterproofing membrane is designed to accommodate the expansion and contraction of the substrate through its flexibility and elasticity. It can stretch and contract along with the movement of the substrate, ensuring a watertight seal is maintained without compromising its integrity.

- Q:Can a waterproofing membrane be used on precast stone block surfaces?

- Yes, a waterproofing membrane can be used on precast stone block surfaces. Waterproofing membranes are commonly used to prevent water penetration and moisture damage in various types of surfaces, including precast stone blocks. These membranes are designed to create a barrier against water, preventing it from seeping into the surface and causing issues such as mold, deterioration, or structural damage. Applying a waterproofing membrane to precast stone block surfaces can help enhance their durability and longevity by protecting them from water-related problems. However, it is important to carefully follow the manufacturer's instructions and ensure that the chosen waterproofing membrane is suitable for the specific type of precast stone block surface being treated.

- Q:Can a waterproofing membrane be used for potable water tanks?

- Using a waterproofing membrane for potable water tanks is not recommended. Although a waterproofing membrane is effective in preventing water penetration and protecting surfaces from moisture damage, it is not suitable for guaranteeing the safety and purity of potable water. To ensure the safety of the water, materials specifically designed and approved for water storage, such as food-grade coatings or liners, should be used for potable water tanks. These materials are formulated to prevent any leaching or contamination of the water, thus ensuring its suitability for consumption. Hence, it is crucial to adhere to industry standards and regulations and utilize appropriate materials when constructing potable water tanks.

- Q:Are there any specific considerations for installing a waterproofing membrane on concrete surfaces?

- Yes, there are several specific considerations for installing a waterproofing membrane on concrete surfaces. Firstly, it is important to ensure that the concrete surface is clean, dry, and free from any loose materials, oil, grease, or other contaminants. Any dirt or debris on the surface can prevent proper adhesion of the waterproofing membrane, compromising its effectiveness. Secondly, it is crucial to inspect the concrete surface for any cracks, spalling, or other damage. These defects should be repaired prior to installing the waterproofing membrane, as they can allow water to penetrate through the membrane and compromise its ability to protect the concrete. Additionally, the type of waterproofing membrane chosen should be suitable for the specific conditions and requirements of the project. There are various types of membranes available, such as sheet membranes, liquid-applied membranes, or cementitious coatings. Each type has different application methods, durability, flexibility, and resistance to various substances, so it is important to select the appropriate membrane for the specific concrete surface and its intended use. Furthermore, the installation of the waterproofing membrane should be carried out in accordance with the manufacturer's instructions. This includes applying the membrane at the recommended thickness, ensuring proper overlap and adhesion of the membrane seams, and using any recommended primers or adhesives. Lastly, it is important to consider the long-term maintenance and durability of the waterproofing membrane. Regular inspections, maintenance, and repairs should be conducted to ensure the membrane remains intact and effective in preventing water penetration.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Waterproof/waterproofing Membrane For Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords