SBS Bitumen Waterproof Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- ONE WEEK PER CONTAINE m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Specification for SBS Waterproofing Membrane:

|

Item |

SBS modified bitumen waterproof membrane | ||||

|

Grade |

First |

Second | |||

|

Base |

PY |

G | |||

|

Cover |

PE |

S |

M |

Al | |

|

Thickness |

2/3/4mm | ||||

|

Color |

Black PE film |

Yellow/green/other Fine Sand |

Grey/Green/other MineralGrains/Flakes |

Aluminium Foil | |

|

Notes |

PY------Polyester Base G-------Glassfibre Base | ||||

SBS/APP modified bitumen waterproofing membrane is made by soaking the base in bitumen,or thermoplas ticityelastomer(such as styrene butadiene-SBS), or thermoplastics (such as atactic polypropylene-APP,APAO,APAL) modified bitumen, then covering double faces with elastomer(SBS) or thermoplastics( APP, APAO,APAL) modified bitumen, and last finiishing the upward face with fine sands, mineral slates(or grains) or polythene membrane ect, while downward face with fine sands or polythene membrane.

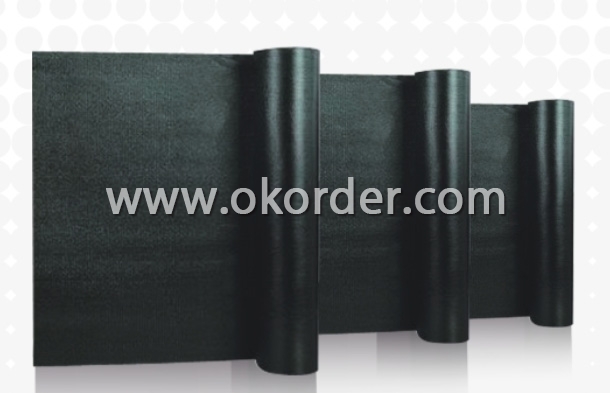

Pictures for SBS Waterproof Membrane:

- Q:Can a waterproofing membrane be used on precast concrete block surfaces?

- Yes, a waterproofing membrane can be used on precast concrete block surfaces. It helps to prevent water penetration and protects the structure from potential damage caused by moisture.

- Q:Can a waterproofing membrane be used for planter boxes or green roofs?

- Yes, a waterproofing membrane can be used for planter boxes or green roofs. In fact, it is highly recommended to use a waterproofing membrane in these cases to prevent water leakage and damage to the underlying structure. A waterproofing membrane acts as a protective barrier, preventing water from seeping into the planter boxes or green roofs and causing potential issues such as rot, mold, or structural damage. By effectively sealing the area, a waterproofing membrane ensures that the water is contained within the intended space, promoting healthy plant growth and preserving the integrity of the structure.

- Q:How does a waterproofing membrane perform in areas with chemical exposure or solvents?

- A waterproofing membrane is designed to provide protection against water penetration, but it may not be effective against chemical exposure or solvents. Chemicals can potentially degrade or damage the membrane, compromising its waterproofing capabilities. It is important to select a membrane specifically designed for chemical resistance if the area is expected to have chemical exposure or solvents.

- Q:Can a waterproofing membrane be used in rooftop gardens or green roofs?

- Rooftop gardens or green roofs can benefit greatly from the utilization of a waterproofing membrane. It is, in fact, imperative to establish a dependable waterproofing system to safeguard the underlying structure against water-related harm. Acting as a hindrance, the waterproofing membrane effectively prevents any infiltration of water into the edifice or potential structural complications. Typically, this membrane is positioned beneath the soil or growth medium of the rooftop garden or green roof, guaranteeing adequate drainage and upholding the building's structural integrity. Furthermore, these membranes are specifically designed to endure exposure to UV rays, temperature fluctuations, and root intrusion, rendering them suitable for prolonged application in rooftop gardens or green roofs.

- Q:Can a waterproofing membrane be used in government or municipal projects?

- Absolutely, government or municipal projects can most certainly utilize a waterproofing membrane. It is, in fact, a vital element frequently employed in the construction or refurbishment of diverse infrastructure projects like roads, bridges, tunnels, and buildings. The purpose of waterproofing membranes is to thwart water infiltration, which may inflict harm upon the structure and undermine its stability. By incorporating a waterproofing membrane, government and municipal projects can guarantee the endurance and robustness of their infrastructure, thereby diminishing the necessity for costly repairs or replacements in the future. Furthermore, these membranes also contribute to energy efficiency by preventing moisture intrusion, thereby reducing the potential for mold growth and enhancing insulation properties. All in all, it is highly recommended to integrate a waterproofing membrane in government or municipal projects to elevate the lifespan and functionality of the infrastructure.

- Q:Can a waterproofing membrane be used in high-rise buildings?

- Yes, a waterproofing membrane can be used in high-rise buildings. It is commonly utilized in high-rise buildings to prevent water infiltration and protect the structure from potential damages caused by moisture. The membrane is applied to various surfaces such as roofs, foundations, and walls to create a barrier against water penetration, ensuring the building remains dry and structurally sound.

- Q:Can a waterproofing membrane be used on precast stone surfaces?

- Indeed, the utilization of a waterproofing membrane is viable on precast stone surfaces. Similar to all other concrete or masonry surfaces, precast stone surfaces are prone to water infiltration, which may lead to long-term damage. By applying a waterproofing membrane onto the precast stone surface, one can effectively prevent water penetration and shield the stone from moisture-related problems such as cracking, spalling, and efflorescence. This membrane establishes a barrier that hinders water seepage into the stone while still permitting it to respire and release any trapped moisture. Hence, it is crucial to select a waterproofing membrane that is compatible with the precast stone material and meticulously adhere to the manufacturer's instructions for proper application.

- Q:Are waterproofing membranes resistant to gasoline vapors?

- Yes, waterproofing membranes are generally resistant to gasoline vapors. They are designed to create a barrier against moisture and other liquids, including gasoline and its vapors.

- Q:Is a waterproofing membrane suitable for use in areas with high groundwater levels?

- A waterproofing membrane works well in areas where the groundwater levels are high. Its purpose is to stop water from getting in, making it an effective barrier against groundwater. These membranes are usually made from materials like bitumen, PVC, or EPDM, which are extremely resistant to water and can handle a lot of pressure from below. They are built to create a tight seal, keeping water out of buildings or underground areas. Because of this, a waterproofing membrane is the perfect choice for places with high groundwater levels. It can successfully guard against water infiltration and the potential harm it could cause to structures or infrastructure.

- Q:Can a waterproofing membrane be used for a restaurant kitchen floor?

- Yes, a waterproofing membrane can be used for a restaurant kitchen floor. Restaurant kitchens are prone to spills and water exposure, so it is essential to have a waterproofing system in place to protect the underlying structure. A waterproofing membrane can provide a seamless and impermeable barrier, preventing water, oil, and other liquids from seeping into the floor and causing damage. Additionally, these membranes are often resistant to chemicals and can withstand heavy foot traffic, making them suitable for the demanding environment of a restaurant kitchen.

1. Manufacturer Overview |

|

|---|---|

| Location | Beijing, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | Mid East; Eastern Europe; North America; Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | Above 50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 600,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Negotiated |

Send your message to us

SBS Bitumen Waterproof Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- ONE WEEK PER CONTAINE m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords