PVC Foam Sheet for Furniture Wall Almirah Designs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

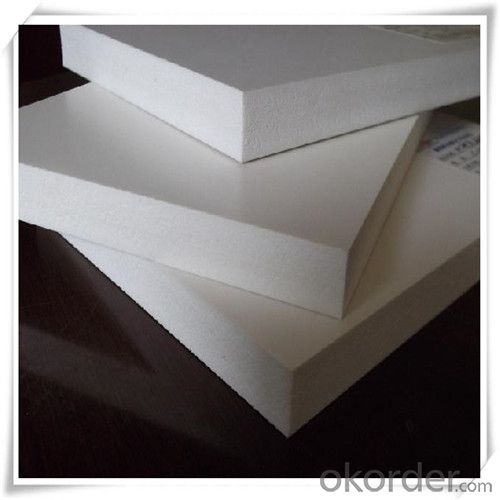

1. Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

Hardness:≥10Mpa

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

5. Product Picture

6.FAQ

Q:We can get the free sample?

A:Of course.

- Q:What types of plastics are used to make plastic sheets?

- There are various types of plastics used to make plastic sheets, including polycarbonate, acrylic, polyethylene, and polypropylene.

- Q:How do you paint gouache on a plastic board?

- Suggest:1, painted on the plastic plate, spray painted liquid, to prevent premature fall;2, do not direct sunlight, do not store in places where the temperature is too high to prevent falling;3, the best use of oil painting, painting, oil paints of a wide range of applications, can be very good attached to the plastic board, dry should not fall off.

- Q:the plastic should be plain without any writting at all.

- Hi: The Local hardware store sells Plexiglas Plastic sheet, However you could be use Poster-board or Cardboard for your templates instead of it ,It's cheaper and you use it to cut the stain glass better if you need it thicker than that, Then Layer it with identical pieces or use it to cut a thick piece of cardboard into the shape, Place it where you want it. Mark it with a felt tip marker. than you can start cutting it out where you want it and then use alcohol to clean the Felt tip marking's off ( use a wax marker to number the pieces) then start soldering or whatever to assemble it I hope this helps

- Q:Are plastic sheets UV-resistant?

- Yes, plastic sheets can be made UV-resistant by incorporating specific additives during the manufacturing process. These additives protect the plastic from the damaging effects of ultraviolet (UV) radiation, helping to prevent discoloration, degradation, and loss of strength.

- Q:A square sheet of plastic measures 1 yard by 1 yard. Square pieces, each 5 inches by 5 inches, are cut from the plastic sheet. What percent of the plastic is wasted?Give your answer correct to one decimal place.A) 5.5%B) 3.6%C) 1.6%D) 0.3%

- 1 - (plastic used)/(total plastic sheet) = 1 - (35)^2 / (36)^2 = 1 - 0,94522 ≈ 0.05478 ~ 5.5 % Σ

- Q:I want to print colour diagram on thermal plastic sheet, but the ink wont dry.

- relies upon on the plastic, yet laminate sheets might probable soften. maximum laser printer have fuser temperatures at or around 400F, so purely plastics particularly made for laser printers could be used.

- Q:Are plastic sheets resistant to chemicals used in pools?

- Yes, plastic sheets are generally resistant to the chemicals used in pools.

- Q:I must be having a brain fart! I can't remember why I bought six rolls of duck tape and heavy gauge plastic sheeting. I remember that it had something to do with the Y2K scare but what the hell? Can someone refresh my memory, please?

- Water collector?

- Q:Are plastic sheets resistant to discoloration?

- Yes, plastic sheets are generally resistant to discoloration.

- Q:I would like it to be something around the house or not to spendy! thanks

- Plastic wrap would work (although it would need to be replaced often) a piece of glass (as was already stated would work best), a glass baking dish could fit over it, etc... pretty much anything clear.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Foam Sheet for Furniture Wall Almirah Designs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords