PVC Coated Plywood for 30 Times Recycling

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plywood :

Plywood is an important parts in construction formwork system , it is with flat surface and with PVC film coated , to make sure the smooth concrete .Our plywood can be recycling 30 times .

Name | Film faced plywood | |

Material | Poplar, combi core, hardwood,brich | |

Size | 1220*2440/ 1250*2500 mm,or as per your request | |

Thickness | 9-25mm | |

Glue | E2, E1, E0,Melamine,WBP, MR | |

Thickness(mm) | 6-27mm | 1/4inch(6-6.5mm) |

1/2inch(12-12.7mm) | ||

5/8inch(15-16mm) | ||

3/4inch(18-19mm) | ||

Moisture | ≤10% | |

Thickness tolerance | ≤ 6mm | +/-0.2mm to 0.3mm |

6-27mm | +/- 0.5mm | |

Packing | For transportation of Ocean and Land, Inside Pallet is wrapped with 0.2mm plastic bag, Steel strip or PVC for strength, More than 2mm plywood sheet or hard paper covering all the sides left, right,top and bottom. | |

Quantity | 20GP | 8 pallets/21M3 |

40GP | 16 pallets/42M3 | |

40HC | 18 pallets/53M3 | |

Usage | Usage Adequate for concrete forming for construction | |

Feature:

1.High bending strength

2.Strong nail holding

3.Resistance to cracking, shrinkage, splitting, and twisting/warping, used instead of plain wood

4.High degree of strength and very hard to bend

- Q:What does plywood mean and its synthesis?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

- Q:What are the plywood specifications?

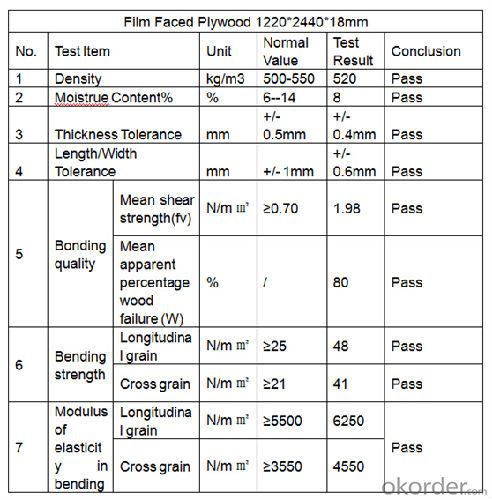

- The physical and mechanical properties of the plywood are described in terms of moisture content, density, thermal conductivity, and bonding strength

- Q:The usual length and width specifications are:

- 1220 × 2440mm, while the thickness specifications are generally: 3,5,9,12,15,18 mm and so on.

- Q:Why is the plywood commonly used in the singular layer

- if put a piece into a striped. (Then this time there will be positive is the pattern of wood

- Q:What kind of glue is today's plywood?

- if you want to make outdoor use of wood products, you can use E1 grade (or even E0 level) phenolic glue.

- Q:Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- Plywood also has solid wood plywood, in general, solid wood panels will be more expensive than plywood

- Q:Judging wood is the standard for plywood

- If you can identify the type of wood used by your own furniture, it will help you identify the true value of the furniture

- Q:according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- Ⅲ, Ⅳ plywood moisture content of not more than 15%). ③ quality. Finished products should have rectangular straight edges and obvious edges and corners;

- Q:How do I determine if plywood contains formaldehyde?

- The plywood itself is easy to identify because each side can see the shavings that are pressed together, but it becomes hard to find it after making furniture

- Q:Today, most of the furniture is made of wood, pine, bakelite and popla

- . At that time, high-quality furniture, timber supply is sufficient, those who are not beautiful or poor durability of wood used only for non-exposed parts of furniture.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Coated Plywood for 30 Times Recycling

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords