PVC Belting Light Duty PVC Conveyor Belts For Food Processing Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

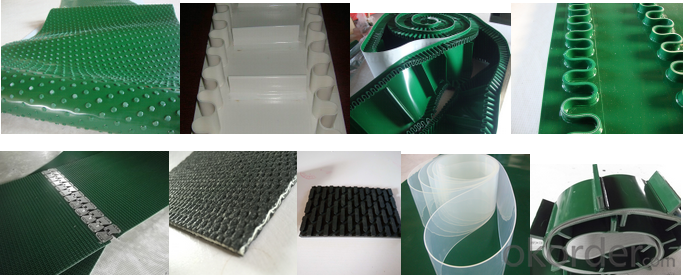

High Quality Light Duty Pvc Conveyor Belts For Food Processing Industry

PVC conveyor belt,PU conveyor belt and some special material,such as silica gel, rubber and etc.

Conveyor belt fabric layers:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

Packaging & Shipping

1.Free for samples, Door-to-Door.

2. By Air or by Sea for batch goods, Airport/ Port receiving.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:Based on customers' quantity. In general,25 days for batch goods.

CNBM:

Listed 267th on Fortune Global 500,2014

Ranking 46th among the top 500 Chinese Enterprises,2013

Ranking 1st of the Chinese building materials industry

Pls contact me freely if any inquiry,thank you!

- Q:How do olive nets help in reducing the risk of sunburn on olive fruits?

- Olive nets help in reducing the risk of sunburn on olive fruits by providing shade and protection from direct sunlight. The nets cover the olive trees, creating a barrier that filters the intensity of the sun's rays. This prevents the fruits from overheating and getting sunburned, which can lead to a decrease in quality and yield. Additionally, the nets also offer protection against hail and birds, further safeguarding the olive fruits.

- Q:Do olive nets affect the nutritional value of the olives?

- No, olive nets do not affect the nutritional value of the olives.

- Q:PC plastic can be welded with any plastic electrode

- PC plastic is welded by ultrasonic, plastic and plastic welding. The ultrasonic welding machine not only can weld PC, but also can weld PE, PP, PS and so on.

- Q:How do olive nets affect the overall appearance of an olive grove?

- Olive nets have a significant impact on the overall appearance of an olive grove. When the nets are spread across the trees, they create a visually striking pattern, transforming the landscape into a sea of green. This uniform and orderly arrangement of the nets enhances the aesthetic appeal of the grove, giving it a more organized and pleasing appearance. Additionally, the nets help to protect the olives from being damaged by birds or falling prematurely, ensuring a higher yield and healthier harvest. Overall, olive nets not only contribute to the beauty of the grove but also play a vital role in maintaining the quality of the olives.

- Q:How do olive nets prevent damage from herbicide drift?

- Olive nets act as a physical barrier that prevents herbicide drift from reaching the olive trees. The fine mesh of the nets blocks the movement of herbicide particles, effectively reducing the risk of damage to the olive trees caused by herbicide drift.

- Q:Can olive nets be used in different soil types?

- Yes, olive nets can be used in different soil types. Olive trees can grow in various soil conditions, such as loamy, sandy, or even rocky soils. The nets are primarily used to collect fallen olives during harvest, which is independent of the soil type.

- Q:Can I make tea with a plastic cup?

- The plastic cups sold in the mall are qualified and unqualified. As consumers, we can only make a simple judgement from the surface of the goods. For example, look at the trademarks, factory name, site, telephone, raw materials, texture, certificate and so on

- Q:Can olive nets be used in combination with rootstock selection methods?

- Yes, olive nets can be used in combination with rootstock selection methods. Olive nets are primarily used to protect the olives from pests and birds, while rootstock selection methods involve choosing the appropriate rootstock for the olive tree based on various factors such as soil conditions and climate. Both methods serve different purposes but can be utilized together to ensure optimal olive tree growth and fruit production.

- Q:Can olive nets be used on olive trees grown in coastal regions?

- Yes, olive nets can be used on olive trees grown in coastal regions. Olive nets are commonly used for various purposes, including protecting olive trees from birds, reducing fruit drop, and facilitating harvesting. Since coastal regions often have a higher bird population, using olive nets can help prevent bird damage to the olive trees and fruits. Additionally, the nets can also provide some protection against strong coastal winds, which can potentially cause damage to the trees. Therefore, using olive nets is beneficial for olive trees grown in coastal regions.

- Q:How does an olive net affect the overall water usage in the olive grove?

- An olive net can significantly reduce water usage in an olive grove. By placing the net over the trees, it helps retain the moisture in the soil by preventing evaporation. This means that less water is required for irrigation, as the net helps maintain a more consistent and efficient water supply for the olive trees.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Belting Light Duty PVC Conveyor Belts For Food Processing Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords