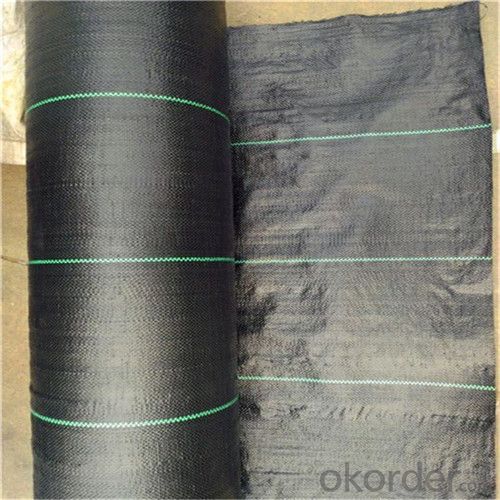

PP Landscape Fabric// Geotextile for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Geotextile Introduction

PP Geotextiles are composed from synthetic polypropylene/polyester fibres through a mechanical process of needling the fabric and adding, when necessary, a thermo fused process, resulting in a uniform porous structure with excellent tensile strength and chemical deterioration.

PP Geotextile Specification

1) Weight / Mass: 75g/m2-400g/m2 .

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP

5) Color: Black , white , grey, others

6) The biggest geotextile manufacturer/factory in China for many years . The equipment is introduced from Germany.

7) This geotextile can be made of polypropylene (PP).

8) The mass is available from 75g/m2 to 400g/m2 and the width available from 1.0m-8m, monolayer or multilayer (reinforcement geotextiles), long fiber or short fiber.

9) Color: all kinds of color are available. The annual production ability is 10 million square meters.

10) The fabric can also be heat treated by infrared at customer's requirements. Our geotextile are UV stabilized to give protection against aging under exposure to natural ultra-violet light.

PP Geotextile Application

1) Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3 )Reinforcement:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4 )Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:The difference between short wire geotextile and filament geotextile

- Geotextile is a collectively, he includes filament geotextile, short wire geotextile, woven geotextile, woven geotextile, hot pressed nonwovens. Polyester filament geotextile color is mainly white, green. Gray two categories. The length of the fiber is greater than 4.5 cm. Strong strength is very high. Looks very good distinction.

- Q:How do geotextiles improve the performance of tunnels?

- Geotextiles improve the performance of tunnels by providing reinforcement, drainage, and filtration functions. They help to enhance the stability of the tunnel lining by acting as a reinforcement layer, preventing soil movement and reducing the risk of settlement. Additionally, geotextiles allow for effective drainage of water, preventing water accumulation that could lead to structural damage or deterioration. They also act as a filtration layer, preventing the migration of fine soil particles into the drainage system, thus maintaining its efficiency. Overall, geotextiles play a crucial role in enhancing the durability, safety, and longevity of tunnels.

- Q:How do geotextiles help with reinforcement of geogrid reinforced walls?

- Geotextiles are used in conjunction with geogrids to reinforce walls by providing additional support and stability. They prevent soil erosion and migration, acting as a barrier between the geogrid and the surrounding soil. This helps to distribute the load evenly, reducing the risk of wall failure and improving the overall strength and durability of the structure.

- Q:250 grams of two cloth a film 0.8 thick geotextile what price

- 250 grams of two cloth a film 0.8 thick geotextile per square meter between about 10 yuan -13 yuan, the current price is the lowest in recent years.

- Q:300g / m2 geotextile permeability coefficient is generally how much?

- Geotextile cloth short fiber geotextile and long fiber geotextile, the two geotextile permeability coefficient is basically the same. According to the requirements of the national standard 300g / ㎡ geotextile permeability coefficient for the K * (10 negative side ~ 10 negative three power), K is between 1.0-9.9 values. From the indicators can be seen 300g / ㎡ specifications of the geotextile has a good water filter, can be used for water, filter them.

- Q:What are the advantages of using geotextiles in green space development?

- Geotextiles offer several advantages in green space development. Firstly, they help with soil stabilization by preventing erosion and promoting vegetation growth. This ensures the longevity of the green space by protecting the soil from being washed away during heavy rainfall or other environmental factors. Secondly, geotextiles can act as a barrier against weeds, reducing the need for herbicides and manual weed removal. This saves time and effort in maintaining the green space. Additionally, geotextiles improve water drainage and filtration, allowing for better moisture retention and preventing waterlogging. This leads to healthier plants and prevents water accumulation which can cause damage. Lastly, using geotextiles can enhance the aesthetics of the green space by providing a clean and uniform appearance. Overall, the use of geotextiles in green space development offers practical and aesthetic benefits, contributing to the successful and sustainable management of these areas.

- Q:What are the factors to consider when selecting geotextiles for landfill applications?

- When selecting geotextiles for landfill applications, there are several factors that need to be considered. These include the strength and durability of the geotextile, its filtration and drainage capabilities, chemical resistance, and its ability to withstand long-term exposure to environmental conditions such as moisture and ultraviolet radiation. Additionally, factors such as cost, availability, and compliance with regulatory requirements should also be taken into account.

- Q:What are the different methods of geotextile testing for strength and durability?

- There are several methods used for testing the strength and durability of geotextiles. These include tensile testing, puncture resistance testing, burst strength testing, tear resistance testing, and abrasion resistance testing. Tensile testing measures the maximum force a geotextile can withstand before breaking. Puncture resistance testing evaluates the ability of a geotextile to resist puncture forces. Burst strength testing measures the pressure at which a geotextile will burst. Tear resistance testing assesses the resistance of a geotextile to tearing forces. Abrasion resistance testing determines how well a geotextile can withstand wear and tear caused by rubbing or scraping. These tests help assess the strength and durability of geotextiles, ensuring they meet the required standards for various applications.

- Q:What are the specifications for geotextiles in gas venting projects?

- The specifications for geotextiles in gas venting projects typically include factors such as the required permeability, strength, and durability. The geotextile should have a high porosity to allow efficient gas flow while preventing the passage of fine particles. It should also possess sufficient tensile strength and puncture resistance to withstand installation and long-term exposure. Additionally, UV resistance and chemical compatibility with the surrounding environment are crucial considerations to ensure the geotextile's longevity and performance in gas venting projects.

- Q:How are geotextiles used in slope stabilization?

- Geotextiles are used in slope stabilization by providing reinforcement and erosion control. They are installed in layers or grids along the slope to increase its stability, prevent soil erosion, and promote vegetation growth. The geotextiles act as a barrier, preventing the movement of soil particles while still allowing water to drain through. This helps to retain the soil and prevent it from sliding or eroding, ultimately stabilizing the slope and protecting it from further damage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Landscape Fabric// Geotextile for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords