Polypropylene Fiber 12mm for Concrete Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Polypropylene fiber Introduction

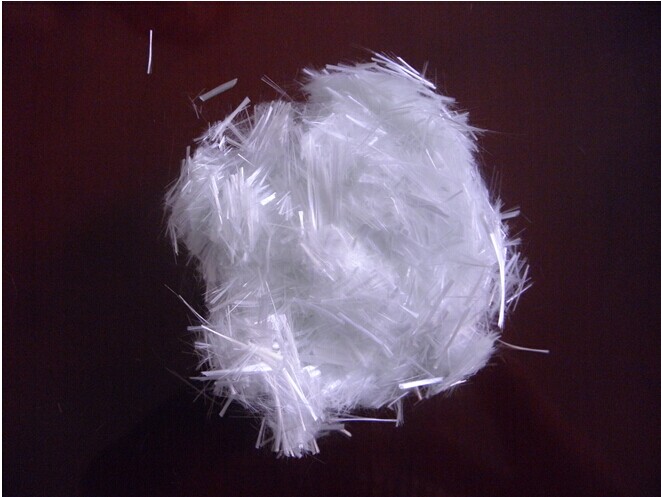

With polypropylene as its raw material, this fiber is produced by special technology,

the products have net-like structure with many fiber monofilaments.

When the fiber is put into the concrete,

the horizontal structure in fiber monofilament can be destroyed in the course of stirring owing

to friction and rubbing, and the fiber monofilament or net like structure will fully stretch,

thus the concrete is reinforced by a great number of polypropylene fibers.

2. Characteristics of Polypropylene fiber 12mm

Appearance | Bunchy monofilametn | Elastic Modulas(MPa) | >3500 |

Density(g/cm³) | 0.91±0.01 | Crack Elongation(%) | >10 |

Shape | Net-like structure or monofilametns | Water-Absorbency | No |

Acid&Alkali Resistance | Strong | Melting Point(°C) | 160-180 |

Tensile Strength(MPa) | ≥560 | Hot conduction | low |

Electrical Conduction | low | Thickness | 25-35um |

3. Application of PP Fiber for Concrete Reinforcement

1)Industrial projects,such as the floor, inner & outer wall;underground waterproof layer,

natatorium/swimming pool, pond and dam, workshop,warehouse and parking lot;

2)Common concrete projects,such as highway, railway,bridge and others;

3)Used as refractory material;

4)Basement of the civil construction

4. PP Fiber advantages:

1.Prevention of the mortar’s contraction crack.

2.Improvement of the wall’s anti-shock and resistance to stripping.

3.Increasing of anti-permeability of wall.

4.Strengthen resistance to freezing and thawing.

5.Improve the ability of protection of reinforcement.

6.Prevent mud crack and crack propagation of mortar.

7.Substitute for steel mesh.

5. FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

6. Product Photos of PP Fiber for Concrete Reinforcement

- Q:Can earthwork products be used in green roof construction?

- Yes, earthwork products can be used in green roof construction. These products, such as soil, compost, and drainage materials, are essential components for creating a healthy and sustainable environment on a green roof. The earthwork products help in providing a suitable growing medium for plants, aiding in water retention, and facilitating proper drainage.

- Q:How are geotextile mattresses used in earthwork?

- Geotextile mattresses are used in earthwork to stabilize and protect slopes, riverbanks, and shorelines. They are typically placed on the surface to prevent erosion by trapping soil particles while allowing water to pass through. These mattresses provide an effective solution for erosion control and can be easily installed and maintained.

- Q:What are the advantages of using geotextile tubes for canal restoration?

- There are several advantages of using geotextile tubes for canal restoration. Firstly, geotextile tubes provide effective erosion control, preventing further degradation of the canal banks. Secondly, these tubes are made of permeable fabric, allowing water to pass through while retaining sediment, which helps in the natural process of sediment deposition and formation of stable canal beds. Additionally, geotextile tubes are easy to install and can be customized to fit different canal sizes and shapes, making them a versatile solution for restoration projects. Lastly, these tubes are durable, resistant to UV degradation and chemicals, ensuring long-term stability and effectiveness in restoring and maintaining canal infrastructure.

- Q:How do geosynthetic liners prevent contamination in waste containment facilities?

- Geosynthetic liners act as a barrier between the waste and the surrounding environment, preventing the leakage of harmful substances. They are designed to be impermeable, ensuring that no contaminants seep into the soil, groundwater, or nearby water bodies. This protective layer effectively contains and isolates the waste, minimizing the risk of contamination and protecting the ecosystem.

- Q:How are geocells used for erosion control on riverbanks?

- Geocells are utilized for erosion control on riverbanks by providing a reinforced structure that stabilizes the soil and prevents its erosion. These cellular confinement systems are filled with soil or other suitable materials, and then placed along the riverbank to create a strong and stable barrier against water flow. The interconnected cells within the geocell system not only enhance the overall strength and stability of the soil, but also promote vegetation growth, further aiding in erosion control.

- Q:What are the different jointing options available in earthwork products?

- The different jointing options available in earthwork products include mechanical jointing, such as using bolts or connectors to secure the pieces together, and adhesive jointing, which involves using adhesives or sealants to bond the pieces. Other options include interlocking jointing, where the pieces have interlocking shapes that fit together, and mortar jointing, which involves using mortar or grout to fill the gaps between the pieces for added stability.

- Q:How do earthwork products help with water quality improvement?

- Earthwork products help with water quality improvement in several ways. Firstly, they can be used to create retention ponds or wetlands, which act as natural filters for pollutants and sediments. These structures capture and retain stormwater runoff, allowing time for sedimentation and the removal of harmful substances before the water is discharged into rivers, lakes, or underground aquifers. Additionally, earthwork products like permeable pavers or gravel trenches can be employed to construct infiltration systems that promote groundwater recharge. By allowing stormwater to infiltrate into the soil, these systems help reduce surface runoff and the transport of pollutants into water bodies. Overall, earthwork products play a crucial role in managing stormwater and protecting water quality by mitigating the impacts of urbanization and promoting sustainable water management practices.

- Q:What are the different types of concrete barriers?

- There are several types of concrete barriers, including Jersey barriers, F-shape barriers, T-shape barriers, and temporary concrete barriers.

- Q:Can earthwork products be used in both residential and commercial projects?

- Yes, earthwork products can be used in both residential and commercial projects. Earthwork products, such as soil, gravel, and sand, are commonly used in various construction projects, including building foundations, landscaping, road construction, and drainage systems, which are applicable to both residential and commercial developments.

- Q:How are geotextile tubes used in sediment control during dredging operations?

- Geotextile tubes are commonly used in sediment control during dredging operations by acting as containment structures for the dredged sediment. The tubes are filled with the sediment and the water is allowed to drain out, leaving behind the solid material. This process helps in separating and dewatering the sediment, allowing for the efficient disposal or reuse of the dredged material while minimizing environmental impacts.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polypropylene Fiber 12mm for Concrete Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords