High Quality PP Fiber Mesh for Concrete Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Fiber Introduction

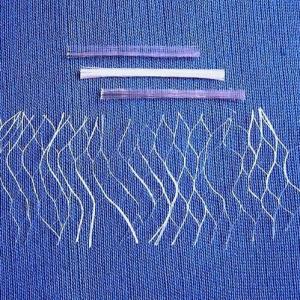

Polypropylene fiber also called PP fiber, is a new type of reinforcing and crack-resistant building material for bitumen concrete reinforcement. It is produced by special technique.With polypropylene as its raw material,fiber-mesh is produced by special technology.It appears net-like structure with many monofilaments connected.

The horizontal structure in monofilament can be destroyed in the course of the stirring owng to friction and rubbing,and the monofilament or net like structure will fully stretch, thus the concrete is reinforce by a great number(more than 7 million pieces per cubic meter) of polypropylene fibers.

Introduction of PP Fiber Mesh for Concrete Use

With polypropylene as its raw material..this fiber is produced by special technology. The products appear net-like structure with many fiber monofilaments connected.

When the fiber is put into the concrete ,the horizontal structure in fiber monofilament can be destroyed in the course of stirring owing to friction and rubbing. And the fiber monofilament or net –like structure will fully stretch, thus the concrete is reinforced by great number of polypropylene fibers.

Technical Data of PP Fiber Mesh for Concrete Use

Density(g/cm3) | 0.91 | Elastic Modulas(MPs) | >3000 |

Length(mm) | 12±1,19±1 | Equivalent Diameter(um) | 100 |

Shape | Beam-like Net | Crack Elongation(%) | 15%-50% |

Acid &Alkali Resistance | Strong | Water-Absorbency | No |

Tensile Strength(MPa) | >350 | Melting Point(C) | 160-170 |

Functions of PP Fiber Mesh for Concrete Use

·increase seepage resistance

·Strengthen spurt & fatigue

·Prolong endurance

·Improve tensile,bending & folding strength

·Improve steel protection

·Improve plastic deformity

·Increase cracking resistance

·Strong acid & alkali resistance and good

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

Application of PP Fiber Mesh for Concrete Use

- Q:Are earthwork products suitable for use in rooftop gardens?

- Yes, earthwork products are suitable for use in rooftop gardens. These products, such as soil, compost, and mulch, provide essential nutrients, improve drainage, and promote healthy plant growth. Additionally, they help retain moisture, reduce erosion, and enhance the overall aesthetic appeal of rooftop gardens.

- Q:What are the different methods of installing earthwork products?

- Some of the different methods of installing earthwork products include excavation and grading, compacting the soil, using geotextiles or geogrids for reinforcement, and installing drainage systems. These methods may vary depending on the specific earthwork product being installed and the desired outcome.

- Q:Can earthwork products be used for creating outdoor dining areas?

- Yes, earthwork products can be used for creating outdoor dining areas. Earthwork products such as gravel, sand, and paving stones can be used to create a solid and level surface for outdoor dining areas. Additionally, landscaping materials like timbers, boulders, and plants can be used to create attractive and functional outdoor dining spaces.

- Q:How are geosynthetic materials used in railway track stabilization?

- Geosynthetic materials are used in railway track stabilization by providing reinforcement and separation functions. They are commonly used in the construction of railway embankments to enhance the stability and load-bearing capacity of the tracks. Geosynthetics, such as geotextiles and geogrids, are installed beneath the ballast layer to prevent the mixing of subgrade soil and ballast, thereby improving drainage and reducing track deformation. Additionally, these materials help distribute the load evenly, increase track longevity, and minimize maintenance requirements.

- Q:How do geopipes help in stormwater management?

- Geopipes help in stormwater management by effectively collecting and conveying excess rainwater or runoff from paved surfaces. They provide a durable and efficient underground drainage system, allowing for the proper disposal or storage of stormwater, reducing the risk of flooding and erosion, and protecting the environment and infrastructure.

- Q:Can earthwork products be used in agricultural projects?

- Yes, earthwork products can be used in agricultural projects. These products, such as soil, gravel, and clay, can be utilized in various ways in agriculture, including land leveling, irrigation system construction, and erosion control. They can help improve soil quality, enhance water management, and prevent soil erosion, contributing to better crop growth and productivity in agricultural projects.

- Q:How are earthwork products used in construction projects?

- Earthwork products, such as soil, sand, gravel, and rocks, are essential in construction projects. They are used for various purposes, including excavation, grading, backfilling, and compaction. These materials are used to create a stable foundation, level the ground, and support structures. Additionally, earthwork products are used in landscaping, drainage systems, and road construction. Overall, they play a crucial role in ensuring the stability and durability of construction projects.

- Q:The Importance of Civil Engineering Materials in Engineering Construction

- Material to determine the process, according to the material to determine the construction methods, materials on the project cost, perception, quality requirements, engage in earthquake design, fire design, energy saving design and so have a very important impact

- Q:What are the benefits of using geonets in landfill gas collection systems?

- Geonets offer several benefits in landfill gas collection systems. Firstly, they provide effective and efficient gas collection by creating a network of channels that allow for the easy flow of gas. This helps maximize the capture of landfill gas, reducing its release into the atmosphere and preventing potential environmental hazards. Additionally, geonets act as a protective barrier by preventing the intrusion of debris and soil into the gas collection system. This helps maintain the integrity of the system and ensures its long-term functionality. Furthermore, geonets enhance the stability of the landfill by providing reinforcement and promoting better load distribution. This can help prevent settlement and subsidence issues, ultimately improving the overall safety and longevity of the landfill. Overall, the use of geonets in landfill gas collection systems can significantly improve gas collection efficiency, protect the system from external factors, and enhance the stability of the landfill.

- Q:What are the different material compositions available for earthwork products?

- Some of the different material compositions available for earthwork products include natural materials such as soil, clay, and sand, as well as synthetic materials like geotextiles, geogrids, and geomembranes. These materials can be used for various purposes in earthwork projects, such as stabilization, erosion control, drainage, and reinforcement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality PP Fiber Mesh for Concrete Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products