Pneumatic Double Flange Butterfly Valve Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

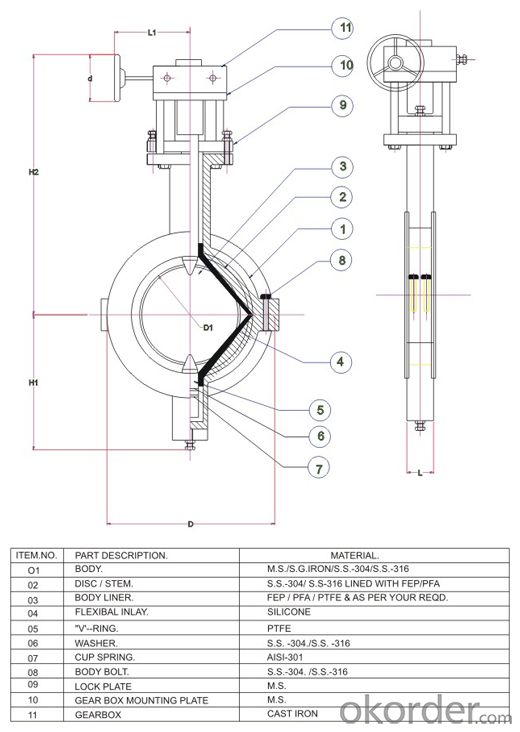

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

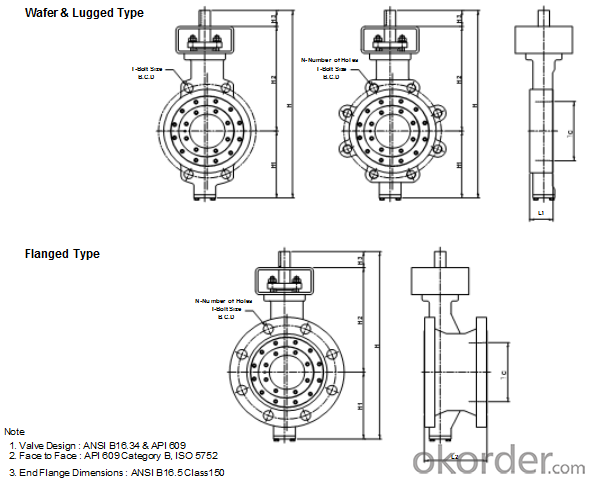

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:The general signal valve installation, or other valve installation is not installed with the groove flange clamp hoop Yucca or direct way? What's the convenient way to install the following diagram? I don't understand. Neither groove, flange nor hoop. Thank you, sir!

- The blue one is the separate body, and the red one is the welded flange on the pipe. There is rubber on the valve body, and it can be sealed with flange. This is determined by the structure of the butterfly valve, usually DN150 of the small diameter butterfly valve are installed this way. It comes with flanges, but the prices are much higher. Small caliber general butterfly valve is generally used for low pressure, leakage requirements are not high, so rarely use its own flange. With flanges, it is generally used in petrochemical systems and has a much higher pressure level.

- Q:How do you calculate the flow of the valve?

- Valve flow calculation value is very vague, pipe pressure, back pressure, medium viscosity, medium temperature, valve structure, and so on, will affect the calculated value.

- Q:What is a lift rod valve?

- The valve stem and valve plate are relatively fixed, and the valve stem rises up when the valve plate is raised

- Q:Hydrant valve leaks, how do you close other valves? Specific steps?

- Crown valve pressFirst, make sure the front of the fire hydrant has a gate valve or butterfly valve Yes, it will be closed and replaced by the lineNo, then useSecond, the pressure of the pipeline to see how big, and if it is rare, replace it with water

- Q:What are the specifications of the valves PN25, DN50?

- Upstairs professional level can be seen very solid.... Clap your hands... Popular speaking, that is, the valve bore is 50, resistance to pressure is below 25, is no problem.

- Q:How does the valve open?

- The general water switch valve and valve is counterclockwise, but there are some special components are clockwise off, specific can correct the switch travel around open to see, do not be too fierce force damage to the switch, you can switch with a wrench

- Q:How about leaking water pipe valve?

- 1, if it is household valveA, the valve and pipe connections at the leakage, in the connection, do not rub tape (the best counter clockwise direction, so that when the valve is connected, the more twisted the more tight) ;B, if the valve itself in the leak, there are ways, it is necessary to open the valve, in which to add sealed or O ring, but it is recommended to replace a more convenient.2, if it is industrial valvesA, industrial valves leaking, if not the valve itself in the leak, then in the valve and pipe connections to join the sealing ring,B, if the valve itself is leaking, it is best to return to the manufacturer for maintenance, if not convenient, then only the manufacturers to come here for maintenance.

- Q:What are the main equipments for valve production?

- Press machine, CNC lathe, instrument lathe, drilling machine, machining center, assembly line, pressure test bench, plane, measuring instruments, etc.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q:Remove the handle and lever the stem rotation with a wrench,

- 1, carbon steel (WCA, WCB, WCC) applies to working temperature between -29 ~ 425 degrees between the middle and high pressure valve. Used for superheated steam. High temperature and low temperature oil, liquefied gas, compressed air, water, natural gas and other media.2 、 low temperature carbon steel (LCB) is suitable for working temperature between -46 ~ 345 Degrees of low temperature valve.3, alloy steel WC6, WC9 is suitable for the working temperature -29 to 595 degrees between the non corrosive medium high temperature and high pressure C5, C12, C12A for working temperature -29 to 650 degrees between the corrosive medium high temperature and high pressure valve.4 austenitic stainless steel for working temperature between -196 ~ 600 degrees corrosion of any medium valve.5,

- Q:What is the difference between the valve before the pump and the valve after the pump?

- Before the pump few valves, up to a foot valve, pump valves, convenient maintenance, then the most important is that the action of check valve backflow, water hammer....

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pneumatic Double Flange Butterfly Valve Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords