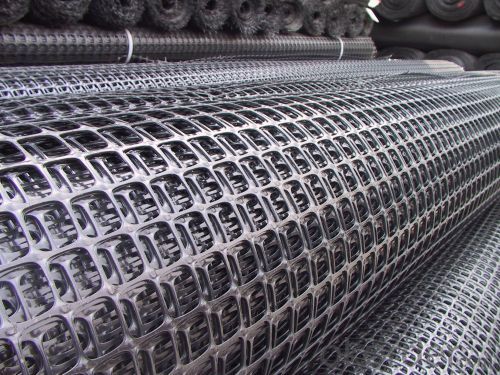

Plastic Biaxial Geogrid for Road Construction 15KN-50KN

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Biaxial PP Geogrid,

Biaxial geogrids are made of macromolecule polymer by the process of being stretched out, formed into lamella, punched regularly and then longitudinal and transverse elongated. They have much higher longitudinal and transverse tensile strength. These structures can supply alinking system to soil, which be used broadly to enable the permanent bearing capacity of roadbed.

Biaxial Geogrid Features:

1. high tension resistance.

2. high plane torsion resistance modulus.

3. good creep resistance and stable chemical nature.

4. high mechanic damage resistance.

5. reduce filling thickness, improve bearing capacity.

Geogrid Features:

(1)High intension,high tenacity,high occlusive force with soil or gravel,erosion-resistant,

water drainage,light weigth.

(2)Reinforce soft soil roadbed,rib side slope of embankment,enhance isolation,

inhibit ground deformation,prevent crack by reflection,increase strength of roadbed.

Geogrid Usages:

1.Increasing the bearing capacity of roadbed and prolonging its service life.

2.Preventing road surface and foundation from subsiding or cracking and keeping clean and beautiful ground surface.

3.Being convenient for construction,saving time and labor, shortening construction period and maintenance cost.

FAQ:

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q:Where is the best geogrid to do?

- Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. Two way, single main look at the design, there are many domestic manufacturers of geotechnical materials, product quality depends on the order contract, to meet the national standards have a lot of. It's all about there.

- Q:Performance parameters of steel plastic geogrid

- gsz30 30 30 30 30 30≤3≤3≤3≤3 232 232 gsz40≥35 40 40 40 40 40≤3≤3≤3≤3 149 149~35≥gsz50(A)50 50 50 50 50≤3≤3≤3≤3 220 220~35≥gsz50(B)50 50 50 50 50≤3≤3≤3≤3 125 125≥35 gsz60(一)60 60 60 60 60≤3≤3≤3≤3 170 170~35≥gsz60(B)60 60 60 60 60≤3≤3≤3≤3 107 107 gsz70 35≥70 70 70 70 70≤3≤3≤3≤3 137 137~35≥80 80 gsz80≤3≤3 80 80 80≤3≤3 113与&;lt;,,/指距> gsz100 113~35≥100 100 100 100 100 100≤3≤3≤3≤3 35≥95

- Q:Are geogrids suitable for use in high groundwater conditions?

- Yes, geogrids are suitable for use in high groundwater conditions. Geogrids are designed to provide reinforcement and stability to soil structures, and they are typically made of durable materials that can withstand the effects of high groundwater levels. Additionally, geogrids have excellent drainage properties, which allow water to flow through and prevent the buildup of hydrostatic pressure. This makes them a reliable choice for applications in areas with high groundwater conditions.

- Q:What is the recommended geogrid junction spacing for specific applications?

- The recommended geogrid junction spacing for specific applications can vary depending on factors such as soil type, load requirements, and slope stability. It is important to consult engineering guidelines and specifications for each specific application to determine the appropriate geogrid junction spacing.

- Q:How to fill in the geogrid evaluation form

- Detection method and frequency in accordance with the requirements, the other reference to your command requirements!

- Q:Can geogrids be used in bridge abutments?

- Yes, geogrids can be used in bridge abutments. Geogrids are commonly used as a soil reinforcement material to improve the stability and load-bearing capacity of soil structures, including bridge abutments. They help distribute the load from the bridge to surrounding soil, reducing settlement and improving overall performance and longevity of the structure.

- Q:Can geogrids be used in reinforcement of retaining walls?

- Yes, geogrids can be used in the reinforcement of retaining walls. Geogrids are commonly used in retaining wall construction to improve stability and strength. They are placed within the soil layers of the wall to provide additional support, prevent soil movement, and increase the overall load-bearing capacity of the structure.

- Q:Where can I do three to the geogrid test?

- There's a lot more to do. The key is where you are. See if there is a recent. The test of top breaking, puncture and tear of geotextiles.

- Q:The difference between polyester glass fiber cloth and glass geogrid

- There are many types of geogrid, glass fiber geogrid is only one kind of geogrid, geogrid also includes polyester grille, steel plastic grille, plastic grille, etc.!

- Q:Can geogrids be used in ground reinforcement for recreational facilities?

- Yes, geogrids can be used in ground reinforcement for recreational facilities. Geogrids provide stability and reinforcement to the soil, making them suitable for applications such as sports fields, playgrounds, and running tracks. They help prevent soil erosion, improve load-bearing capacity, and enhance the overall durability of the ground, ensuring a safe and reliable surface for recreational activities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Biaxial Geogrid for Road Construction 15KN-50KN

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords