Polypropylene Biaxial GeoGrid with CE Certificate with High Tear-resistance for Soil Reinforcement

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 122000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polypropylene Biaxial GeoGrid with CE Certificate with High Tear-resistance for Soil Reinforcement

1. Introudction for Polypropylene Biaxial GeoGrid with CE Certificate with High Tear-resistance for Soil Reinforcement

Plastic earthwork grid is a drawing of a square or rectangle of polymer mesh material, according to its manufacture different stretching direction can be unidirectional and bi-stretch. It is in the extruded polymer sheets (raw materials for PP or HDPE) punch, and heating purposes of directional stretch. Unidirectional grid only stretch along plate length direction, which is biaxially oriented grid continues to be one of the grid and then in the direction of its length vertical stretch.

2. Features for Polypropylene Biaxial GeoGrid with CE Certificate with High Tear-resistance for Soil Reinforcement

a). Low Elongation

b).High Tensile Strength

c). Warp / Weft: tensile strength(kn/m): 15,20, 30, 40, 50

d). High Tear-resistance

3. Specifications and Technical Data for Polypropylene Biaxial GeoGrid with CE Certificate with High Tear-resistance for Soil Reinforcement

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

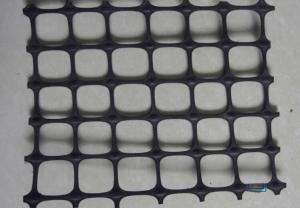

4. Some photos for Polypropylene Biaxial GeoGrid with CE Certificate with High Tear-resistance for Soil Reinforcement

- Q:Fiberglass grille and geogrid which use more

- Fiberglass geogrid is glass fiber rovings as the main raw material, the reticular structure material of the knitting process, for the protection of glass fiber and improve the overall performance, through a special coating treatment process and the formation of new excellent soil substrate.

- Q:Are geogrids suitable for railway track stabilization?

- Yes, geogrids are suitable for railway track stabilization. Geogrids are commonly used in railway construction and maintenance projects to enhance the stability and load-bearing capacity of the tracks. They provide reinforcement and prevent lateral movement of the ballast, helping to reduce track settlement and increase track longevity. Geogrids also improve the overall performance and safety of the railway infrastructure by minimizing track deformations and improving drainage.

- Q:What are the factors that affect the design of geogrid-reinforced structures?

- The factors that affect the design of geogrid-reinforced structures include the type and strength of geogrid material, soil properties (such as strength and settlement characteristics), loading conditions, design life requirements, construction techniques, and potential environmental factors (such as temperature variations and chemical exposure). Additionally, factors such as site-specific conditions, project constraints, and regulatory requirements may also influence the design of geogrid-reinforced structures. Overall, a comprehensive understanding of these factors is crucial to ensure the optimal design and performance of geogrid-reinforced structures.

- Q:How to determine the number of geogrid detection method

- What are the geogrid testing items1) place: in the surface layer of 50cm thick sand gravel or sand (egg) gravel cushion, and compaction, which is not only conducive to improve the friction between the soil and the grid, but also conducive to the consolidation of the foundation drainage.

- Q:How does the steel plastic geogrid stretch? Where do you have a special fixture to sell? What is the best thing to use?

- Steel plastic geogrid price steel plastic geogrid specification steel plastic geogrid roleWhich is the professional manufacturer of steel plastic geogrid?Poi634 | browse 331Posted on 2017-02-21 12:33 best answerPlastic geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other additives by extrusion become composite high strength tensile band, and surface roughness is embossed, high strength reinforced geotextile. The single belt is formed by the longitudinal and horizontal spacing or the clamping arrangement, and the welding joint is formed by adopting the welding technology of special strengthening bonding to weld the joint

- Q:How do geogrids improve the performance of geosynthetic-reinforced slopes in seismic zones?

- Geogrids improve the performance of geosynthetic-reinforced slopes in seismic zones by providing additional stability and reinforcement to the soil. They act as a strengthening element within the slope, enhancing its resistance to the dynamic forces generated during seismic events. The geogrids effectively distribute the loads throughout the slope, reducing the potential for slope failure or displacement. This reinforcement mechanism helps to maintain the integrity and overall stability of the slope, mitigating the adverse effects of seismic activity.

- Q:Geocell of earthwork grid construction method

- Engineering application of geocell1, deal with half fill roadbedOn the ground of natural slope in 1:5 acts on the slope of embankment, embankment should be dug in steps, step width not less than 1M when the stage of building or rebuilding highway widening, convergence of old and new subgrade embankment slope, excavation step should be of high grade highway, the step width is 2M, the laying of geocell in each layer step on a horizontal plane, using geocell own facade side limit reinforcement effect, the problem of uneven subsidence of a better solution.2, sandy area roadbedSandy area on the low embankment subgrade, filling height is generally not less than 0.3M. due to the Low Subgrade Construction of sandy area and heavy bearing professional requirements, the geocell can play on the loose packing lateral confinement effect, with high stiffness and strength in the limited height of subgrade protection, to load large vehicle stress.3, the back embankment fillThe geocell reinforced abutment can achieve the purpose of better, geocell and fillers can generate enough friction, effectively reduce the roadbed and structures between uneven settlement, can effectively alleviate the "final abutment jump" disease of the early impact damage of bridge deck.

- Q:Can geogrids be used in reinforcement of bridge abutments and wing walls?

- Yes, geogrids can be used in the reinforcement of bridge abutments and wing walls. Geogrids are high-strength synthetic materials that can improve the stability and load-bearing capacity of soil structures. In the case of bridge abutments and wing walls, geogrids can be installed to provide additional reinforcement, reducing the potential for settlement and enhancing the overall performance and longevity of the structure.

- Q:Can geogrids be used in reinforcement of underground storage facilities for hazardous materials?

- Yes, geogrids can be used in the reinforcement of underground storage facilities for hazardous materials. Geogrids are highly effective in providing soil reinforcement and stabilization, which is crucial for ensuring the structural integrity and safety of underground storage facilities. By enhancing the load-bearing capacity of the surrounding soil, geogrids can help prevent ground movements and potential leaks or ruptures, thereby minimizing the risks associated with storing hazardous materials.

- Q:What are the factors that affect the installation time of geogrids?

- The factors that affect the installation time of geogrids include the size and complexity of the project, the type and condition of the soil, the equipment and manpower available, the weather conditions, and any potential obstacles or site constraints that may need to be addressed.

1. Manufacturer Overview |

|

|---|---|

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Polypropylene Biaxial GeoGrid with CE Certificate with High Tear-resistance for Soil Reinforcement

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 122000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords