Plain Aluminum Aluminio for Pre-Insulated Insulated Panel Ductwork

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Plain Aluminum Aluminio for Pre-Insulated Insulated Panel Ductwork

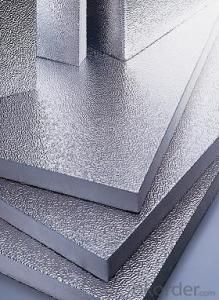

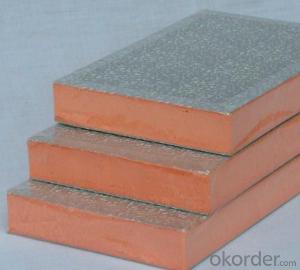

1.Structure of Plain Aluminum Aluminio for Pre-Insulated Insulated Panel Ductwork

Air ductwork supply is pre-insulated aluminum panels constructed of both aluminum and Poly-isocyanurate. The sandwich panels are comprised of expanded Poly-isocyanurate rigid foam board, faced on both sides by aluminum foil.Ducting is the key part of any central air-conditioning system. It is similar in function to the arteries and veins in the human body as it helps in regulating the temperature in a building. The material used for making ducts for air-conditioning is constantly evolving in order to satisfy the demand for higher thermal efficiency, eco-friendliness, and increased energy savings. Many different materials and systems such as magnetite composite, PVC and so on have been developed as alternatives to the galvanized sheet metal used traditionally. But pre-insulated ducting materials is by far the most popular ducting system in use today. It is essentially a panel made with an insulating material such as PIR (Polyisocyanurate), PUR (Polyurethane) or Phenolic foam material sandwiched in between two layers of aluminium foil. Such a foam panel is easier than traditional galvanized sheet metal to manipulate for complex designs and lighter than its predecessors for installation. These qualities in addition to the fact that it has a much higher thermal efficiency than galvanized sheet metal make it an ideal material for fabricating Airconditioning ducts in harsh climates like the Gulf. Its application has been gradually extended to every type of air distribution system: industrial and commercial.

For construction of air ducting in HVAC systems, the Polyisocyanurate (PIR), PUR (Polyurethane) and/or Phenolic foam panel with 45kg/m3 density, coated with 80/80µm thick embossed aluminum foil have two panel types:

The air ducts fabricated using ALU 80/80 panels can be installed in plants:

with air speed up to 15m/s

with pressure up to 1000Pa

indoor

The air ducts fabricated by using ALU 80/200 panels can be installed in plants:

with air speed up to 35m/s

with pressure 1750Pa

outdoor

2.Main Features of Plain Aluminum Aluminio for Pre-Insulated Insulated Panel Ductwork:

Air Duct Panel / Pre-insulated Duct Panel / HVAC Duct Panel :

HVAC Aluminum Foil Duct Board

1. Be used for HVAC Duct system;

2. BS 476 Part 6&7 Class 0.

3. Low thermal conductivity.

3.Plain Aluminum Aluminio for Pre-Insulated Insulated Panel Ductwork Images

Our embossed aluminum sheet/Coil series include:

1.diamond embossed aluminum sheet/Coil

2.orange peel embossed aluminum sheet/Coil

3.stucco embossed aluminum sheet/Coil

4.Plain Aluminum Aluminio for Pre-Insulated Insulated Panel Ductwork Specification

Air-conditioning Areas Exposed to weather

Thickness of panels 20 Mm 30 Mm

Thickness of aluminum 80/80 Microns 80/200 Microns

Density of the foam 44-48 Kg/m3 42-48 Kg/m3

Finishing of aluminum Embossed Embossed

Dimension Length: 4meter Width: 1.2meter

Note: Both sides of the aluminum foil are lacquered with a 3g/m2 weatherproof and ultraviolet ray protection polyester lacquer.

Certificate: FORM A, CO ,FORM E ,FORM B ,MTC, SGS and ROHS(client paid for it), MTC

Surface Quality: without any dent, scratches, oiliness , oxidation .

Chemicial composite and Machinary Property: Meet with GB/T, JIS,ENAW, ASTM standard

Month Capacity: 5000MT/month

exporting port: Tianjin, Shanghai

payment: TT or LC at sight

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long for your delivery time?

Commonly 30 working days can be served. If you need the products urgently, we can shorten the delivery time into 20 days.

3. Where the Panels can't be used?

As extractors in the kitchen, as chimneys for smoke or chemical laden smoke

As transportation for solids

Outside temperature range -35ºC and +110ºC

Air speed >15m/s for 20mm thick panel and >35m/s for 30mm thick panel

when the negative or positive pressure inside the duct is: 20mm thick panel >1000Pa and 30mm thick panel >1750Pa

- Q:My 4 year old got some nail polish on my comforter and sheet on my bedHow do I remove it from fabric? I tried nail polish remover but it only makes it lighter and doesn't remove it.

- Soak the spots in a bowl of full strength nail polish removerJust wad the entire area right into the bowlLet it sit for a whileThe polish should waft offMake sure you don't spill any nail polish remover on anything valuable(You might sit the bowl on top of aluminum foil or some other form of protection.) Then launder the comforter and sheet as usual.

- Q:What's the raw materials of high-precision alumimium foil?

- It's the high-precision aluminium. Aluminium foil is produced by constant rolling and annealing.

- Q:My question is, why there are differences between the british enlish and our enlish?I really don't understand, I know that the quot;realquot; english is the british one, but i don't know why some words change, I understand that the pronunciation change, but the words? Why? I really wanna know that.

- This Site Might Help YouRE: How Can I cure myself of Claustrophobia? Four months before my fourth birthday, my mother let me play with some of the kids who lived next door and across the streetThey took me down the street to where a house was being builtThey stuffed me into some kind of tube or pipe and left me thereI couldn't get outIt was Dallas and.

- Q:What do you make that is quick, and tasty?Please don't say carry-out or take-awayI already figured that out! :-))

- Take a large square of heavy duty aluminum foil and fold the sides up to make a packagePlace a boneless chicken breast in the center and season well with whatever you're hungry for at the moment - barbeque sauce, teryaki sauce, lemon pepper, dill butter, or whatever you fancyPlace a quartered, peeled potato, a carrot cut into chunks, a few brocolli spears, and some slices of onion (if you like it )around the chickenDot the veggies with a little butter, salt, and pepper, then fold the foil up to make a tight packageBake at 350 degrees until the chicken is done and the veggies are cooked(Usually about 25 to 30 minutes.) Serve with a deli salad of your choice and some warm garlic breadsticksIt's good, easy, covers most of the food groups, and there's little clean-up.

- Q:My father had a business were he sold gun ammoIn May the business caught on fire and all the ammo in the metal cases went offI have 4 ammo cases( probably over 500 rounds) that he gave me and told me to turn it in for the moneyI have no clue about ammoMost of the cases look like brass to me, but some look copper and so do the tips that went off and were still in the boxI just would like to get this stuff out of my garage and recycledI thought about just taking them to the recycling center and taking their word for what is copper and what is brassAny help would be great.

- No, they make brass, steel, aluminum and even plastic cases The ones you have probably are not copperMost likely copper colored brass.

- Q:Can I get away with 3/4quot; EMT? Or do I need regular square tubing? I will have to bolt it for now as some stole my welder.BQ: How do you get a dog used to a hack?

- You won't get better than the previous answerIn the days of long ago, in the UK, fingering was what we called sock yarn.

- Q:Ok so i have an Angel G7 gun, a Torque 440 hopper, a Pure Energy 48/3000 aluminum tank, a Vents Helix Mask, Viewloader 150 round pod(s) with hip strap, a Dye c6 Jersey, Charger and original owners manual for gun, gun/equipCase and an extra set of eyes for the gunHow much yall think i can get out of it everything is in great condition no probs whatsoever

- Depands a lot on the condition of the gun and the hopperAs far as the tank, is it in date or not and how much time is left on itThe jersey and casereally not much thereBut Nercore is right, in good (working) condition, $400 max.

- Q:so, I made an awesome pipe out of a book but I don't know what to make the bowl out of since I heard smoking out of foil is bad and it makes it taste weird and much more harshany ideas?

- You have anxietyI wouldn't care what human douchebags think about you though thats what i realized now i can live the rest of my sht life in this shthole world.

- Q:What are some cheap environmental upgrades I can make on my house?

- You can use aluminum foil on your windows to keep your house warmer in the winterIt will keep it quite a bit warmer Start recycling your plastic bags by bringing them to the store and packing your groceries in them instead of using the ones that the store gives youTell the cashier you will bag your own groceries Use labels to put over the envelopes you recieve from others in the mail and tape them to re use the envelopes instead of purchasing a new box Rip your old towels and use them as rags instead of tossing them out.

- Q:I have to do a project for science, and my topic is recyclingI have found out from my research that if you recycle one aluminum can, it saves enough energy to run a TV for 3 hoursI am a little confused, as to if the recyled can is giving the energy for the tv or what?Please Help! Any would be appreciated! I would like it quite soon so i could further my research instead of contemplating this statement for soo long!

- Use Hello Hydration from Herbal Essences And theres a mix it works really good! mix a couple eggs and milk together then pour on your hair and leave it for 5 minutesIt's amazing! And rinse of course.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plain Aluminum Aluminio for Pre-Insulated Insulated Panel Ductwork

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords